ITEM SPECIFICS

-

Brand

KBH

-

origin

Republic of Korea

-

Size(Capacity)

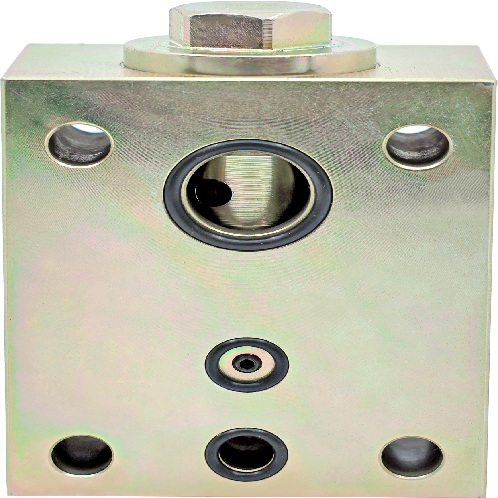

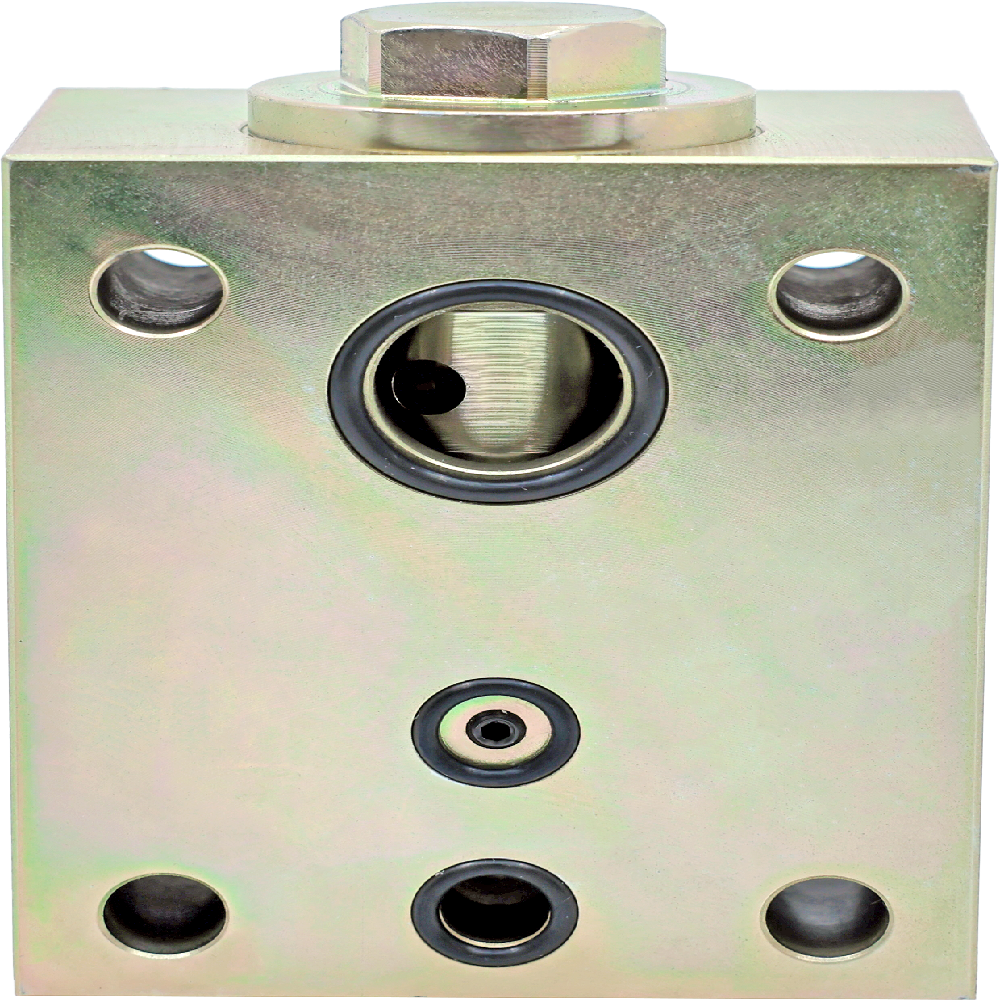

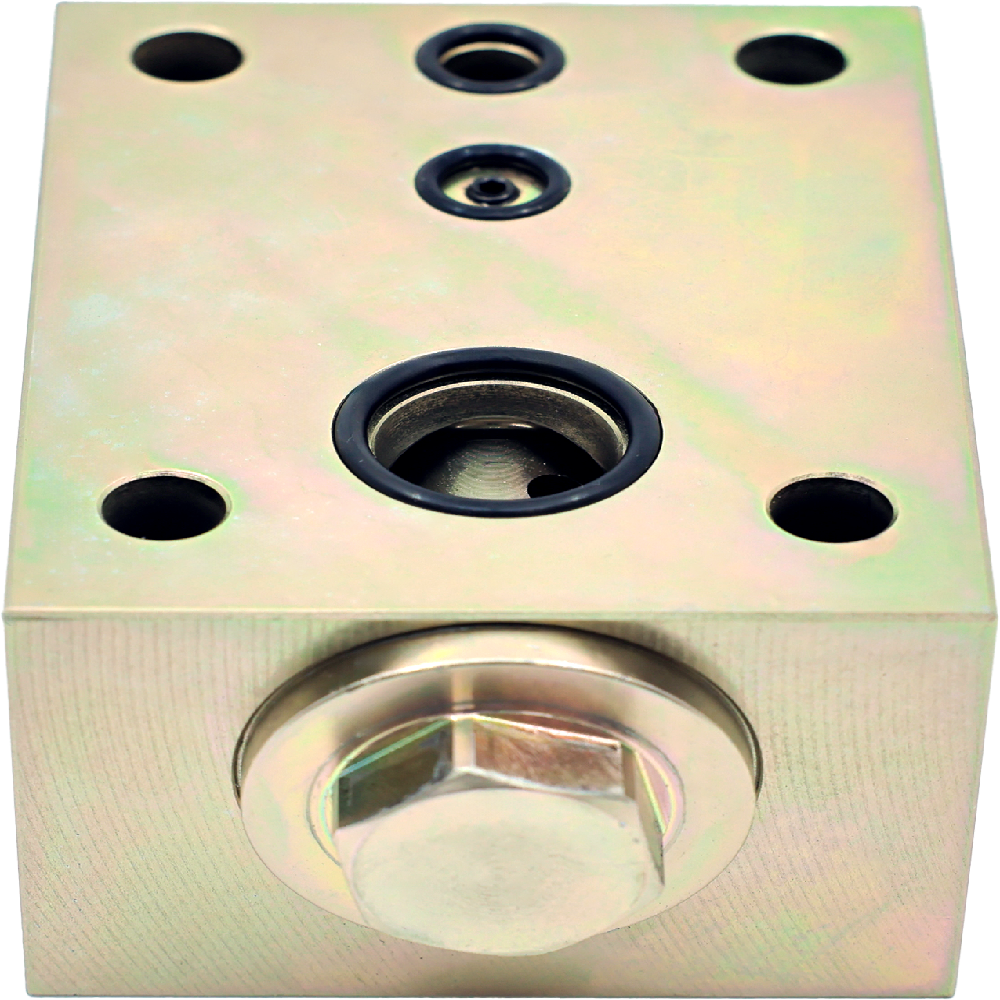

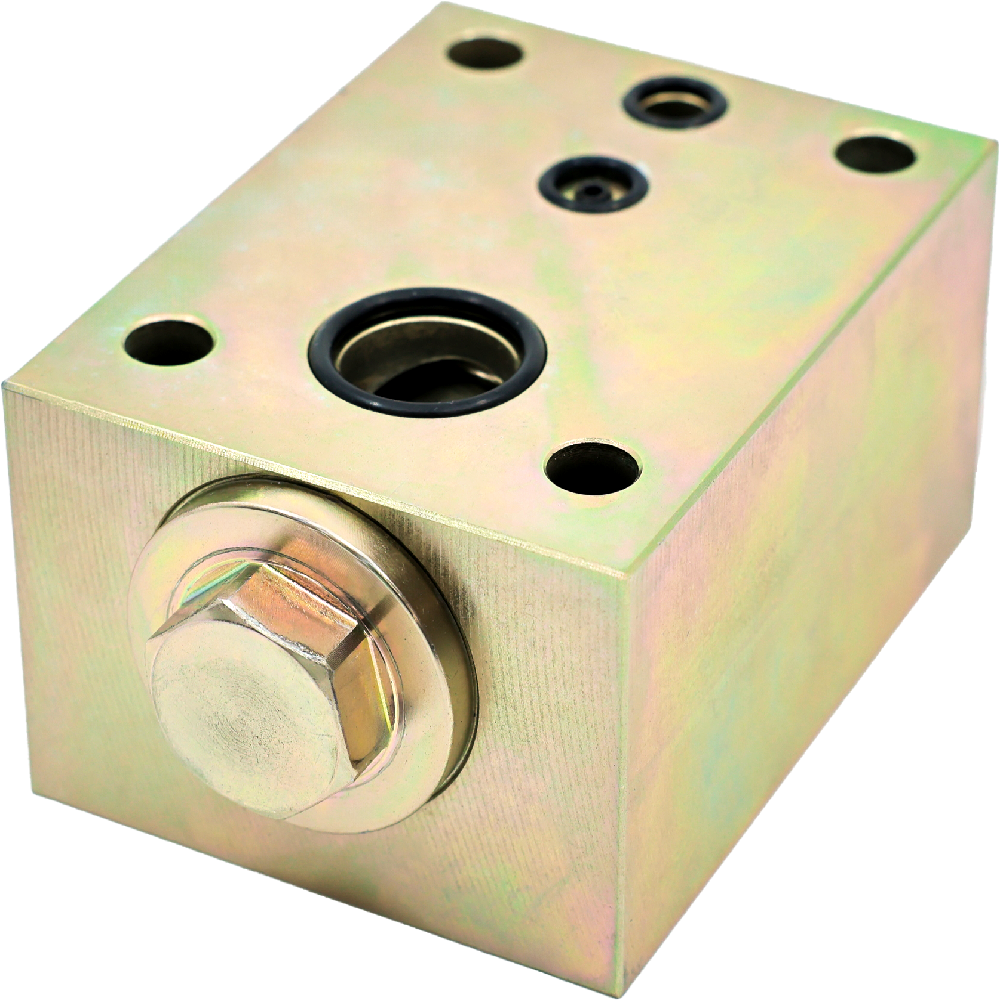

Check Valve

PRODUCT DESCRIPTION

A check valve is a type of valve that allows fluid to flow in only one direction. In other words, a check valve prevents backflow of fluid. It is commonly used in pipeline systems to control the direction of fluid flow and prevent backflow that could damage other components or equipment in the system.

Here are the main features and functions of a check valve:

- Backflow Prevention: The check valve ensures that fluid flows only in the intended direction, preventing backflow. If fluid flows in the reverse direction, the internal disk or flap of the valve closes, blocking the backflow.

- Backflow Prevention: The check valve ensures that fluid flows only in the intended direction, preventing backflow. If fluid flows in the reverse direction, the internal disk or flap of the valve closes, blocking the backflow.

- Automatic Operation: Check valves operate automatically without the need for manual intervention. They open when fluid flows in the designated direction and close when the flow reverses.

- Structure: Check valves come in various types, such as 'spring check valves,' 'disk check valves,' and 'ball check valves.' Each design differs in how the valve opens and closes in response to fluid flow.

- Applications: Concrete Pump Truck, Check valves are used in applications like pump systems, piping, fluid processing systems, boilers, and cooling systems to prevent backflow and ensure system stability.

Check valves are critical safety devices that play an essential role in maintaining system efficiency and reliability.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Nelly Kim

SHIPPING

Shipping from :

Afghanistan

- 9-36 Tangeum-gil Bongsan-myeon, Damyang-gun, Jeollanam-do (57371)

KBH Co., Ltd.

KBH Co., Ltd.

Seller_MailThe person in charge

GYEONG BIN ROHAddress

9-36 Tangeum-gil Bongsan-myeon, Damyang-gun, Jeollanam-do (57371)

Introduction

KBH has been advancing for over 20 years, proudly showcasing outstanding technology and quality in the field of precision machining.

Based on the latest machining skill, we precisely manufacture high-quality components according to customer requirements.

We can provide optimal solutions across various industries through strict quality control and continuous technological innovation.

As your reliable partner, we will grow together with our customers.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Hydraulic Parts, Hydraulic Valve, Hydraulic Block, Hydraulic Cylinder, Hydraulic Motor

-

- Established :

- 2004-01-01

-

- Total Annual Revenue :

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items