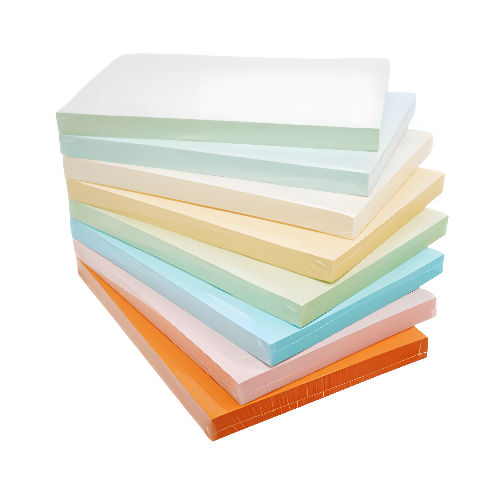

Clean Room Paper (0.3mm/250gsm)

-

Payment

T/T

-

MOQ

250 Set

-

Supply Ability

1,570 Set per One-Time

-

Supply Details

Customization Sample Order

100 pieces(sheets) = 1 set(bag)

-

Country of sale

World Wide, Asia, Middle East, Americas, Africa

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model YJCP-B30Y-Jun

-

origin

Republic of Korea

-

Size(Capacity)

788mm x 1091mm (As a standard size) (Our products are available in customized sizes.)

-

Material

Autoclavable

-

Function

Interleaf, Lead frame, Separetor, Packaging for Electronic parts, Printing, Labelling Semi-conduct

-

Weight

250 gsm

-

Dimensions

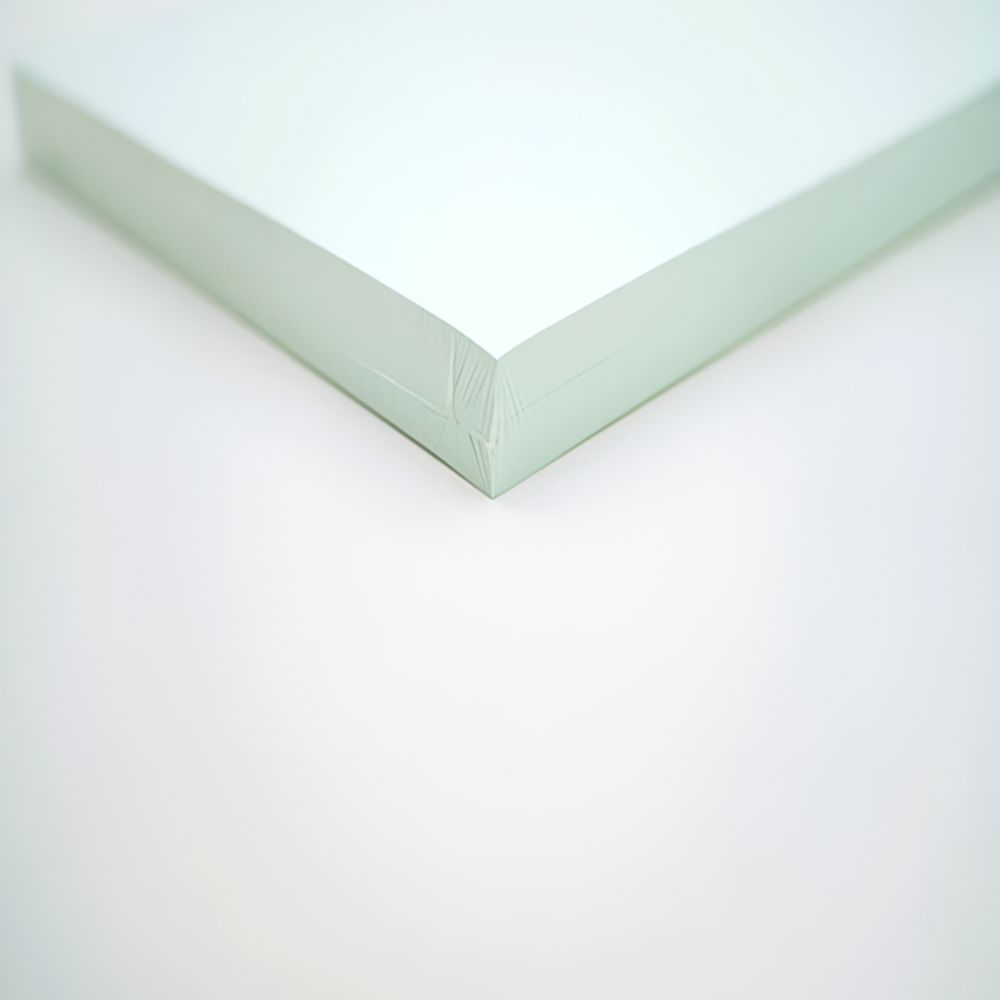

Thickness 0.30 (mm)

-

Condition

Tensile strength ,kg/15mm (MD) : 26 , Tensile strength ,kg/15mm (CD) : 23

-

Features

Ash(%) : 0% , Moisture (%) : 4%

-

Style

Size and color as Customers' requirements

PRODUCT DESCRIPTION

Key Features and Benefits

-

1. Autoclavable and Contaminant-Free:

-

This clean room paper is fully autoclavable, ensuring it maintains sterility and cleanliness in sensitive environments. It contains 0% ash, making it entirely free from residual contaminants that could compromise product integrity.

-

-

2. High Tensile Strength for Durability:

-

The paper provides reliable tensile strength:

-

26 kg/15mm (MD) in the machine direction

-

23 kg/15mm (CD) in the cross direction

-

-

These specifications ensure the paper’s robustness and reliability, even for demanding applications.

-

-

3. Low Moisture Content:

-

With a moisture content of just 4%, the paper maintains its structural integrity in controlled environments. This characteristic prevents warping and ensures consistency in performance.

-

-

4. Lightweight and Flexible Design:

-

At 0.3mm thickness and a basis weight of 250gsm, this paper is exceptionally lightweight while maintaining sufficient strength. It is easy to handle and use, making it an efficient choice for various operations.

-

-

5. Customizable Sizes and Colors:

-

The product’s full size is 788mm x 1091mm, with options for complete customization to suit unique requirements. Tailor the paper to fit specific applications seamlessly, enhancing productivity and efficiency.

-

Applications

-

1. Interleaf and Lead Frames:

-

Ideal for use as an interleaf material, this clean room paper provides a protective barrier between components such as lead x-frames, semiconductor parts, and electrical parts.

-

-

2. Separator for Electronic and Semiconductor Parts:

-

The paper’s lightweight yet durable design makes it an excellent choice for separating high-value components, reducing the risk of damage or contamination.

-

-

3. Printing and Labelling:

-

The smooth surface of the clean room paper allows for precision printing and labeling, ensuring clean and professional results.

-

-

4. Packaging for Sensitive Parts:

-

Protect critical components, including circuit boards and precision instruments, with durable and lightweight paper that offers superior moisture resistance.

-

Technical Specifications

-

Model: YJCP – B30

-

Full Size: 788mm x 1091mm (Custom sizes available upon request)

-

Basis Weight: 250gsm

-

Thickness: 0.3mm

-

Tensile Strength: MD (Machine Direction): 26 kg/15mm , CD (Cross Direction): 23 kg/15mm

-

Ash Content: 0%

-

Moisture Content: 4%

-

Design Style: Customizable size and color

Value Proposition

By incorporating Clean Room Paper into your manufacturing or packaging processes, you can:

-

Ensure Product Integrity: Prevent contamination and damage to sensitive components, ensuring compliance with clean room standards.

-

Enhance Operational Efficiency: The paper’s lightweight and durable structure reduces handling effort while maintaining protection.

-

Tailor to Specific Needs: Customizable sizes and colors allow seamless integration into diverse applications, maximizing product utility.

PAYMENTS DETAILS

- Telegraphic Transfer : T/T

- Name : Steven Youn

SHIPPING

- 55 Solan-gil (10911)

- Sea Freight : Please contact us for carriers inquiry

- Sea Freight : possible

- Please contact your administrator for detailed information.

- Name : Steven,Youn

- Tel : 82-010-8896-2742

The person in charge

Steven YounAddress

55 Solan-gil, Paju-si, Gyeonggi-do (10911)

-

-

- Business Type :

- Trading Company

-

- Main Product :

- PE Foam Sheet, Clean Room paper

-

- Established :

- 2006-01-01

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- Y-JUN Co.,LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★