[SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System

-

Payment

P@yGOS(PayPal)

-

MOQ

1 Set

-

Supply Ability

9,999 Set per Month

-

Supply Details

Customization

-

Country of sale

Asia, Americas, Europe, Middle East, World Wide

-

PRICE

-

EXW

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model [SMART PC] PRECAST CONCRETE[SMART PC] PRECAST CONCRETE

-

origin

Republic of Korea

-

Size(Capacity)

Free

-

Features

Protective Walls

-

Condition

new

PRODUCT DESCRIPTION

PC Functional Concrete Fabrication - Defense Spaces and Protective Walls

Overview - Military facilities, equipment, and bomb shelters and air defense systems of troops

1. Currently, the frontline GOP and GP are constructed as facilities that are very vulnerable to surprise attacks by enemy forces

2. In the event of a combat situation, we are concerned that the rate of loss of combat power of elite troops in the early stages of the war will be very high

3. The type of barrier currently in use

A. Field construction type barrier: tire stacking, drum stacking, soil filling type wire mesh, sand bar.

Emergency construction at the discretion of the commander of the unit is mainly performed, there is no standard,

there is a large deviation in protection capacity, and the protection capacity is not guaranteed in case of the second

attack after the first attack.

B. Structural barrier: laminated blocks, earth and sand filled waveform steel plate, concrete T-wall

There is no guarantee of protection from secondary shells, no protection against small drones at all, and no variability

in the protection target.

2. In the event of a combat situation, we are concerned that the rate of loss of combat power of elite troops in the early stages of the war will be very high

3. The type of barrier currently in use

A. Field construction type barrier: tire stacking, drum stacking, soil filling type wire mesh, sand bar.

Emergency construction at the discretion of the commander of the unit is mainly performed, there is no standard,

there is a large deviation in protection capacity, and the protection capacity is not guaranteed in case of the second

attack after the first attack.

B. Structural barrier: laminated blocks, earth and sand filled waveform steel plate, concrete T-wall

There is no guarantee of protection from secondary shells, no protection against small drones at all, and no variability

in the protection target.

Product Characteristics

What is functional concrete (protective wall)?

Functional concrete keeps soldiers and equipment safe from threatening attacks such as portable rocket bombs.

It effectively prevents secondary damage by suppressing the occurrence of debris scattering on the back of the protective wall due to explosion pressure during shelling to ensure the life and safety of combat soldiers.

It effectively prevents secondary damage by suppressing the occurrence of debris scattering on the back of the protective wall due to explosion pressure during shelling to ensure the life and safety of combat soldiers.

It is manufactured using a rescue vehicle operated by the South Korean military, an engineer unit 0.6W excavator, and

a Sinuk helicopter without using civilian operation equipment.

Made in weight and size, it can be quickly installed anywhere.

a Sinuk helicopter without using civilian operation equipment.

Made in weight and size, it can be quickly installed anywhere.

Concrete removed internal and external configurations

The hollow multi-x-layered structure effectively increases the protection against the thickness of the structure, and is efficient to install and transport it with a lower weight than the protection.

Functional Concrete for Building Protection (Protection Wall)

As soon as they are exposed to unimaginable danger, the lives of the combatants are defenseless and the battle lines collapse.

When using a general concrete barrier where there is a risk of shell attack, the rear debris effect can seriously hurt combat soldiers by debris and secondary debris.

Not choosing a special barrier exposes the safety and lives of combatants to the greatest threat.

Special barriers are the best option for protecting the safety of the people and the Armed Forces and the security of the country.

Special barriers are the best option for protecting the safety of the people and the Armed Forces and the security of the country.

Protective walls for roadblocks and checkpoints, air raid shelters (both used as obstacles to track vehicles)

Barriers for roadblocks and checkpoints play an essential role in road control.

The barrier protects the combatants with its role as a roadblock.

The barrier protects the combatants with its role as a roadblock.

The barrier acts as an obstacle to vehicle and orbital tram entry.

Air protection slabs protect combatants from aerial attacks such as drones and effectively prevent secondary damage.

Air protection slabs protect combatants from aerial attacks such as drones and effectively prevent secondary damage.

Durable functional barriers are designed to protect combat soldiers in dangerous situations and contribute greatly to traffic control and threat detection.

It is quickly deployed in emergency situations and is the best structure for responding to potential threats in a strategic location.

It is quickly deployed in emergency situations and is the best structure for responding to potential threats in a strategic location.

As a PC structure, it can be constructed for a very short period of time and can be easily constructed with military equipment such as a Sinuk helicopter and a 0.6W excavator.

Protective barrier system for critical equipment protection

Portable direct fire extinguisher for field barracks, outposts, and expensive equipment storage rooms

Safely protected from (RPGs, Jung-gu police machine guns, other bullets, etc.).

Safely protected from (RPGs, Jung-gu police machine guns, other bullets, etc.).

arched protective slab

It is made of arches (made of functional concrete) to enhance protection and is longitudinally segmented for ease of transport and construction and protection from aerial attacks.

It is made of arches (made of functional concrete) to enhance protection and is longitudinally segmented for ease of transport and construction and protection from aerial attacks.

L-type barrier

Both sides are combined with arch protection slabs, and the front and rear sides are spaced apart by the entrance/exit space to secure protection on four sides.

Both sides are combined with arch protection slabs, and the front and rear sides are spaced apart by the entrance/exit space to secure protection on four sides.

expectation effectiveness

Efficiency of individual fighters and positions

1) Each fighter and position connected to a traffic signal improves the concentration of combat by protecting against heavy machine guns and portable rockets (RPGs), concealing from drones, and installing roofs against snow or invisible objects

2) It consists of three components and can be moved from the Tonguejae Army Engineer to the 0.6W excavator in operation. Excavation → Installation → Re-fill, which is expected to take 30 minutes to 1 hour to install

2) It consists of three components and can be moved from the Tonguejae Army Engineer to the 0.6W excavator in operation. Excavation → Installation → Re-fill, which is expected to take 30 minutes to 1 hour to install

Economic and Expedited Construction of a Large Area

1) When installing protective structures near the top of the mountain or in remote areas, such as observation stations, command stations, communication bases, preoccupancy sites, etc., can be transported in the air (not more than 6 tons) or can be assembled and constructed without additional concrete installation at the site

2) It can be installed and constructed in places where access to private construction vehicles is difficult, and it may not be necessary to open and restore temporary roads for construction (it can be transported by helicopter or excavator), which minimizes forest damage and provides excellent economic feasibility

3) Construction and assembly manuals are simple, so engineering units can be installed independently (no private professionals required)

2) It can be installed and constructed in places where access to private construction vehicles is difficult, and it may not be necessary to open and restore temporary roads for construction (it can be transported by helicopter or excavator), which minimizes forest damage and provides excellent economic feasibility

3) Construction and assembly manuals are simple, so engineering units can be installed independently (no private professionals required)

Practicality as a barrier to bullets

1) The different variations of our products can be used in many forms of operations.

① Obstacles and individual combat positions to block the wide road

② unmanned equipment protection facility

③ a fence in a facility that requires reinforcement of protective force

④ an emergency checkpoint

⑤ I'm ready for it

⑥ an improvised post, living quarters, etc

⑦ Important equipment protection facilities

② unmanned equipment protection facility

③ a fence in a facility that requires reinforcement of protective force

④ an emergency checkpoint

⑤ I'm ready for it

⑥ an improvised post, living quarters, etc

⑦ Important equipment protection facilities

product price stability

Our products form a factory price with a certain thin pattern compared to weight, volume, and protection capacity, so there is little probability of irregular cost increases due to poor construction sites.

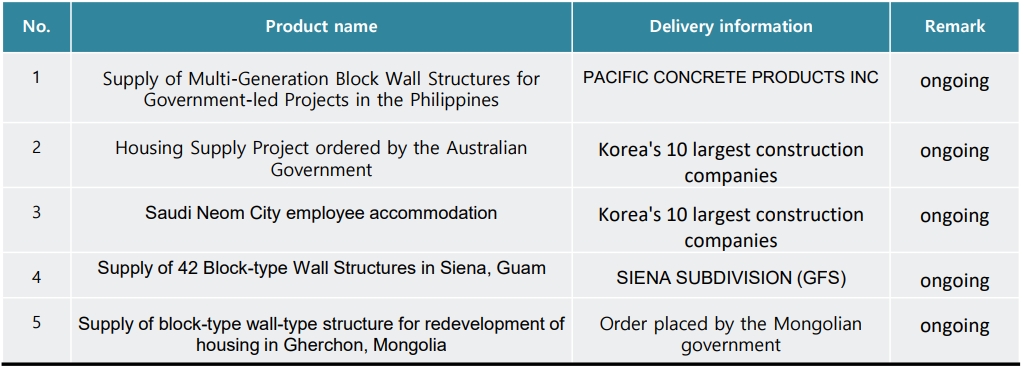

Status of overseas progress and partnership status

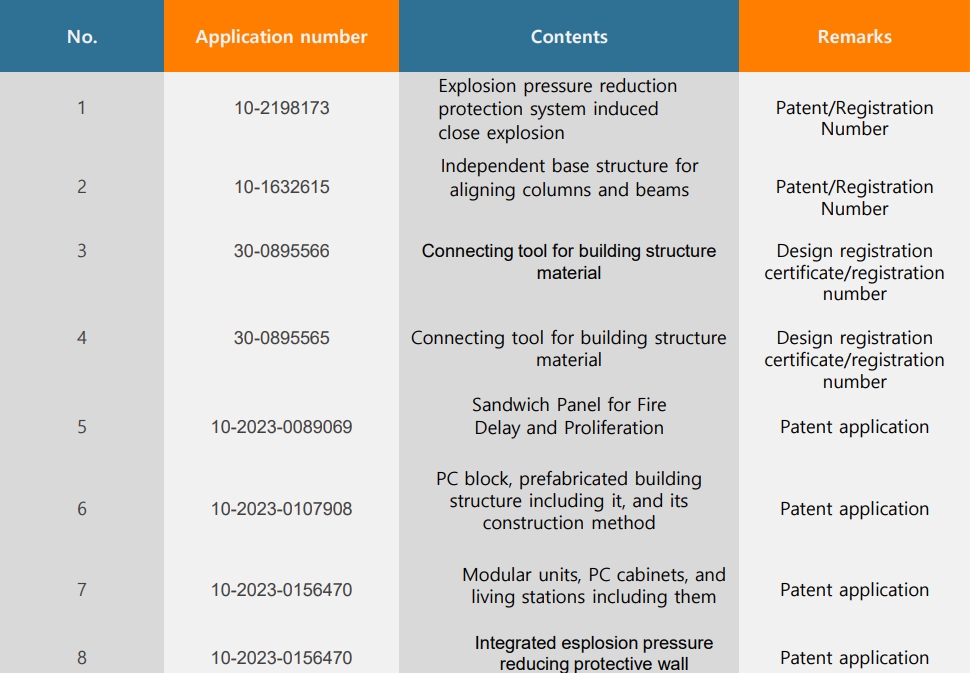

Status of key technology holdings

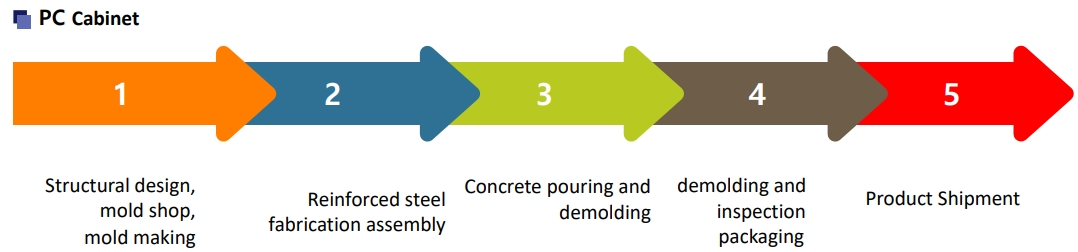

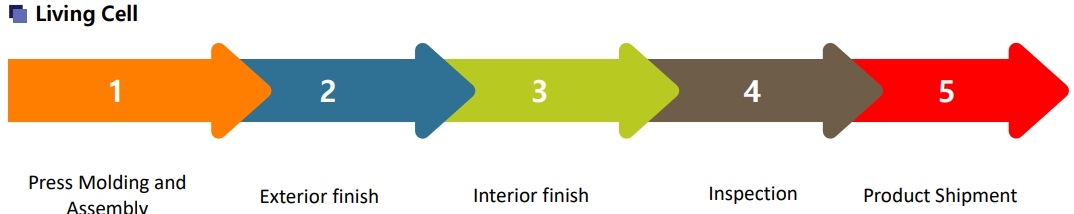

Production process chart

PATENT CERTIFICATE

PAYMENTS DETAILS

This payment are available by Gobiz.com system.

- P@yGOS(PayPal) Contact Payment Manager

- Name : You Hyekyoung

SHIPPING

Shipping from :

Afghanistan

- 71 Jojeong-daero (12919)

- Sea Freight : Please contact us for carriers inquiry

- Sea Freight : possible

- Please contact your administrator for detailed information.

- Name : You,Hyekyoung

- Tel : 82-02-511-8907

UHK SYSTEM

The person in charge

You HyekyoungAddress

71 Jojeong-daero, Hanam-si, Gyeonggi-do (12919)

회사소개

UHK SYSTEM

Introduction

UHK SYSTEM is a trading company with aspirations to introduce and distribute the best specialties related to Korea's eco-friendly, social trends and cultural issues to the world.

1. Global and new idea products

2. Products that prioritize safety and health

3. Best high-tech products

Major Products

1. Solid Precast Concrete prefabricated structure-SMART PC method.

2. Construction of Reinforced Concrete Wall Module Factory and Rapid Accurate Construction/

Precast Concrete Explosion pressure reduction shock wave dispersion barrier function

3. Korean Government Procurement Products- Interactive Whiteboard

4. Candida bacteria 99.99% sterilized female cleanser certified as cosmetic

5. Korea Public Procurement Service registered solar LED waterproof dustproof road sign stud

6. Long life with capacitor charging 100% fully independent high efficiency capacitor solar streetlight

* UHK SYSTEM will continue to upgrade our wonderful products.

We will always strive to become a global company that values customer stability, eco-friendliness, and future vision.

-

- Business Type :

- Distributor/Wholesaler

-

- Main Product :

- PC precast concrete construction, electronic whiteboard, women's products, etc

-

- Established :

- 2003-09-24

-

- Total Annual Revenue :

-

- Total Employees :

- Less than 5

R&D CERTIFICATE

-

- ISO 9001, ISO 14001, ISO 22716

- ITS

- 2020.10.01

- 인증서보기

-

- Candina bactericidal test (ASTM E2315-16)

- Korea testing & research institute

- 2024.04.08

- 인증서보기

-

- Deodorization test

- Korea standard test researcher

- 2023.10.23

- 인증서보기

-

- HACCP

- Korea Food Safety Management Certification Service

- 2023.03

- 인증서보기

-

- MS 1500 : 2009

- HALAL - KARAJAAN MALAYSIA

- 01 April 2

- 인증서보기

-

- MA 1500 : 2009

- HALAL - KERAJAAN MALAYSIA

- 2013. 04.

- 인증서보기

-

- HALAL MS 1500 : 2009

- KERAJAAN MALAYSIA

- 2013.04

- 인증서보기

-

- Super Capacitor Test Report

- SGS

- 2022.4.28

- 인증서보기

-

- Registration certificate for broadcasting and comm

- National Radio Research Institute

- 2022.05.12

- 인증서보기

-

- KC certificate(Safety confirmation report certific

- KTR(Korea Chemical Convergence Test Researcher)

- 2022.06.10

- 인증서보기

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- UHK SYSTEM Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

![video thumbnail [SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System youtube](http://img.youtube.com/vi/6NEppT3YHXg/mqdefault.jpg)

![full image [SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=MAIN_THUMB082)

![detail image1 [SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI1_THUMB082)

![detail image2 [SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI2_THUMB082)

![detail image3 [SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI3_THUMB082)

![detail image4 [SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI4_THUMB082)

![[Greentouch] Ultra Slim IR Interactive Electronic Whiteboard Best Writing Technology](/image/goodsImage.do?goods_no=GS2024121245164&image_se_code=MAIN_THUMB174)

![[SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=MAIN_THUMB10A)

![[SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI1_THUMB10A)

![[SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI2_THUMB10A)

![[SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI3_THUMB10A)

![[SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI4_THUMB10A)

![[SMART PC] Impact Pressure Shock Wave Dispersion Blocking Function Concrete Wall System](/image/goodsImage.do?goods_no=GS2024121245161&image_se_code=ADI5_THUMB10A)