ITEM SPECIFICS

-

Brand

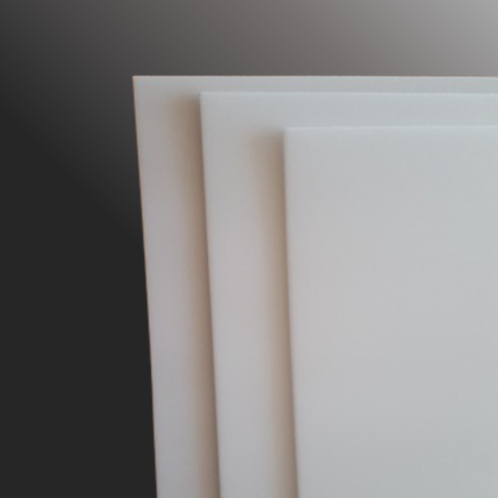

Model YJEF – 17 (SERIES)Y-Jun

-

origin

Republic of Korea

-

Size(Capacity)

550mm X 1000mm (Any size is available)

-

Function

Interleaf, Lead frame, Separetor, Packaging for electric parts, Semi-conductors parts and Electric

-

Material

Polyethylene

-

Package Includes

2.5 / 2.0 / 1.8 / 1.5 / 1.3 / 1.2 / 1.0 / 0.8 / 0.6 /0.5 (mm) (Any thickness is available)

-

Color

White

PRODUCT DESCRIPTION

Key Features and Benefits

1. Exceptional Protection for Sensitive Components:

The high-quality polyethylene material ensures outstanding durability and shock absorption. These properties make the foam sheets ideal for safeguarding delicate electronic parts, semiconductor components, and other fragile items during transportation and storage. By minimizing the risk of damage, businesses can reduce costs associated with returns or replacements.

2. Versatile Applications:

These foam sheets are perfectly suited for packaging electronic parts, semiconductor parts, and electrical components. Additionally, their adaptability allows for usage in various industries that prioritize item safety and protection. Whether you are shipping high-value items or storing sensitive components, this product ensures your materials remain intact and undamaged.

3. Customizable Thickness and Dimensions:

Our foam sheets are available in thicknesses ranging from 2.5mm to 0.5mm and standard dimensions of 550mm x 1000mm. We also offer customization options for specific sizes and thicknesses to meet unique business requirements. Tailoring the product to your needs enhances efficiency and optimizes packaging processes.

4. Durable and Cost-Effective:

The polyethylene foam’s resilience to wear and tear ensures long-term usability, making it a cost-effective solution for repeat packaging and protection. By investing in durable materials, businesses can lower overall operational expenses.

5. Environmental Considerations:

Designed with a commitment to sustainability, these foam sheets are lightweight, requiring less energy during transportation. This feature helps reduce the carbon footprint of your shipping operations, aligning with global sustainability goals.

Ideal Applications

1. Electronic Parts Packaging: Safeguard sensitive components such as PCBs, sensors, and processors during transit. The foam’s non-abrasive surface prevents scratches and maintains the integrity of your products.

2. Semiconductor Part Protection: Ensure safe handling and delivery of semiconductor wafers, chips, and other delicate parts. The shock-absorbing capabilities of the foam sheets reduce the risk of impact damage.

3. Custom Foam Sheet Designs: Tailor the foam sheets to accommodate unique product shapes and sizes. This flexibility is particularly valuable for businesses requiring bespoke packaging solutions.

Technical Specifications

-

Standard Size: 550mm x 1000mm (Custom sizes available upon request)

-

Thickness Range: 2.5mm, 2.0mm, 1.8mm, 1.5mm, 1.3mm, 1.2mm, 1.0mm, 0.8mm, 0.6mm, 0.5mm

-

Material: High-density polyethylene foam

-

Custom Design: Available based on customer requirements

Value Proposition

By incorporating our Polyethylene Foam Sheets into your packaging and protection processes, you can expect:

-

Reduced Damage Rates: Minimize product loss and improve customer satisfaction with superior packaging materials.

-

Cost Efficiency: Save on packaging and shipping costs by utilizing lightweight yet durable materials.

-

Sustainability Goals: Align with environmentally conscious practices through energy-efficient transportation.

PAYMENTS DETAILS

- Telegraphic Transfer : T/T

- Name : Steven Youn

SHIPPING

- 55 Solan-gil (10911)

- Sea Freight : Please contact us for carriers inquiry

- Sea Freight : possible

- Please contact your administrator for detailed information.

- Name : Steven,Youn

- Tel : 82-010-8896-2742

The person in charge

Steven YounAddress

55 Solan-gil, Paju-si, Gyeonggi-do (10911)

-

-

- Business Type :

- Trading Company

-

- Main Product :

- PE Foam Sheet, Clean Room paper

-

- Established :

- 2006-01-01

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- Y-JUN Co.,LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★