ITEM SPECIFICS

-

Brand

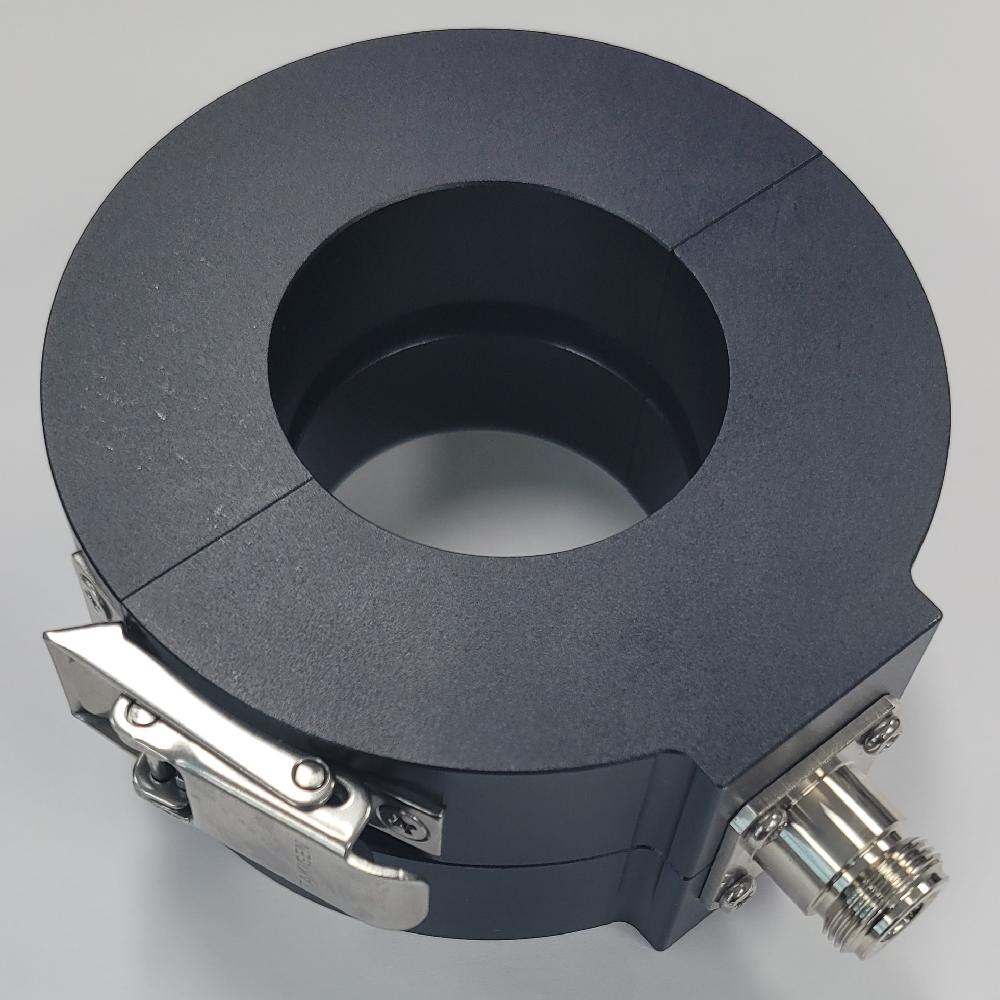

OPM400

-

origin

Republic of Korea

-

Size(Capacity)

200Wx255Hx110.5D(mm)

-

Material

Aluminum (AI)

-

Color

Gray

-

Weight

2.5kg including accessories

PRODUCT DESCRIPTION

"Among the core elements of power facilities, the most widely used mold transformers are monitored and analyzed online at all times, and failure signs are diagnosed through composite deterioration to predict them in advance and prevent power outages.

○ Application of various diagnostic sensor technologies.

(UHF band UHF sensor, HF band HFCT sensor, wide-angle IR thermal imaging camera)

(UHF band UHF sensor, HF band HFCT sensor, wide-angle IR thermal imaging camera)

○ Application of mold transformer analysis algorithm and LCD display to enable immediate on-site diagnosis.

○ Automatic transmission of faulty location data to upper SCADA. 1. Development and application of various diagnostic sensors for early prediction of abnormal deterioration of mold transformers and improvement of reliability of fault detection. → Diagnostic sensors: UHF sensor, HFCT sensor, IR thermal imaging sensor application. 2. Constant checking of deterioration status of mold transformers through LCD screen on site and diagnosis through remote monitoring maximizes convenience of mold transformer management. 3. Additional data according to numerous power systems and usage environments on site are also being accumulated, so product stability is improved through product Up-Grade that is appropriate for the right place.

OPM200 → OPM300 → OPM400 Upgrade. 4. Development of optimal application of diagnosis and sensors by applying thermal imaging camera with field of view that can diagnose 3 phases at once in a narrow space of low-voltage part of mold transformer."

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Keunseop Choung

SHIPPING

Shipping from :

Republic of Korea

- 31 Galmachi-ro 244beon-gil Jungwon-gu, Seongnam-si, Gyeonggi-do (13212)

OPENG

The person in charge

Gilsu ChoiAddress

31 Galmachi-ro 244beon-gil Jungwon-gu, Seongnam-si, Gyeonggi-do (13212)

Introduction

OPENG stands for Online-Power System Engineering. Co., Ltd., and purpose of our company is to provide offline & online testing service, analysis, solution and others to prevent accident and stabilize power system as a leader of electrical facilities preventive diagnosis company.

-

- Business Type :

- Manufacturer

-

- Main Product :

- OPM200

-

- Established :

- 2006-01-10

-

- Total Annual Revenue :

- 8~9 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- Korea Testing Laboratory For quality control

- Korea Testing Laboratory

- 2020.08.11

- 인증서보기

-

- Korea Testing Laboratory For reliability verificat

- Korea Testing Laboratory

- 2020.08.11

- 인증서보기

-

- Korea Testing Laboratory For reliability verificat

- Korea Testing Laboratory

- 2020.08.29

- 인증서보기

-

- Korea Electrotechnology Research Institute Test Re

- Korea Electrotechnology Research Institute

- 2015.05.20

- 인증서보기

-

- KP20-YYP0448

- KCTL

- 2020.06.15

- 인증서보기

-

- KP20-HEZ0089

- KCTL

- 2020.06.15

- 인증서보기

-

- KP20-YYP0447

- KCTL

- 2020.06.15

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 8~9 billion (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items