Heat Transfer Printable Vinyl, One Print

-

Payment

L/C(sight) , OT , T/T

-

MOQ

200 meter (m)

-

Supply Ability

200,000 meter (m) per Month

-

Supply Details

Customization Sample Order

Minimum order quantity varies according to the item and roll size.

-

Country of sale

World Wide, Asia, Americas, Africa, Middle East

-

PRICE

-

FOB

USD 2.60 ~ 6.20

(1 meter (m))

-

CIF

USD 2.60 ~ 6.20

(1 meter (m))

-

EXW

USD 2.60 ~ 6.20

(1 meter (m))

-

ITEM SPECIFICS

-

Brand

Model PTODAE HA

-

origin

Republic of Korea

-

Size(Capacity)

Width 500mm x Length 50M / roll

-

Function

Heat transfer vinyl for garment

-

Material

PU(=Polyurethane) layer

-

Color

White

-

Weight

Gross weight: 7.54 kg / roll

-

Expiry Date

1year from the manufacturing date

-

Condition

New

PRODUCT DESCRIPTION

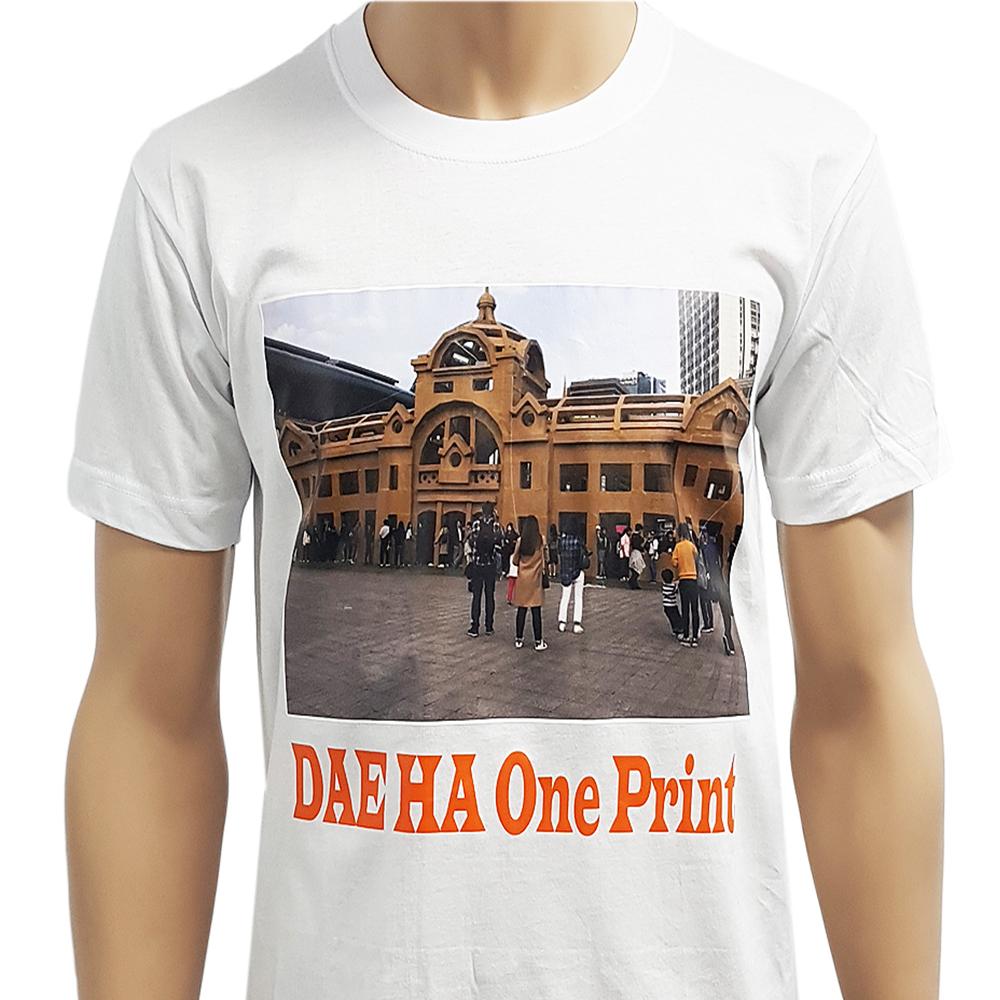

Heat Transfer Printable Vinyl, One Print

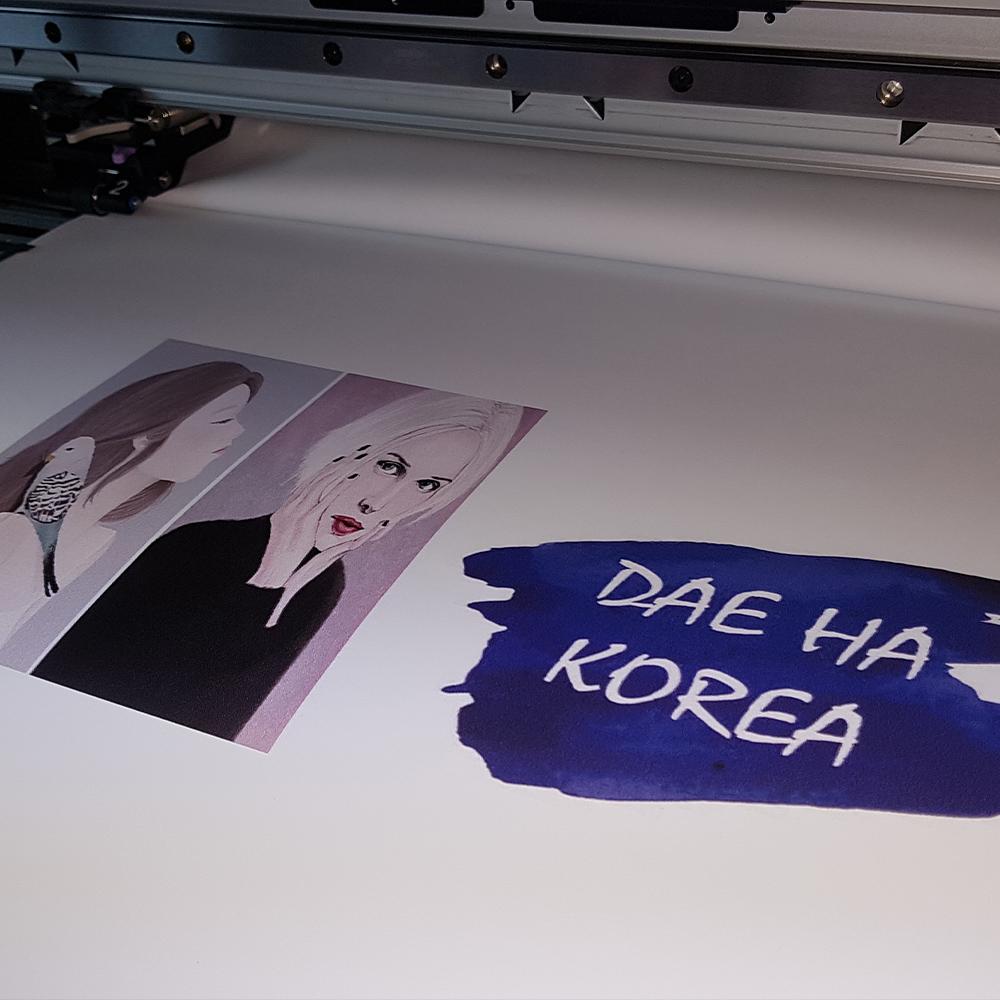

Dae Ha One Print is environment-friendly printable PU material suitable for Eco Solvent inks. You can produce full color digital transfers for designs or logos on leisure, fashion and sportswear and the printed colors on One Print is vivid and clear. And it has a great advantage that does not take long time to dry the designs after printing and an adhesive backing enables intricate cutting.

Advantages of One Print

ㆍVivid and clear color printing

ㆍSuitable for Eco solvent inks on print & cut machines such as Roland, Mimaki or etc.

ㆍAn adhesive backing enables intricate cutting

ㆍInstant drying with bright print results

ㆍBrilliant white base film which is very easy cut and weed

ㆍExcellent wash durability

ㆍSuitable for Eco solvent inks on print & cut machines such as Roland, Mimaki or etc.

ㆍAn adhesive backing enables intricate cutting

ㆍInstant drying with bright print results

ㆍBrilliant white base film which is very easy cut and weed

ㆍExcellent wash durability

Thickness of One Print

ㆍSkin: 30mic.

ㆍHotmelt: 60mic.

ㆍTolerance ±20 microns

ㆍSticky liner

ㆍHotmelt: 60mic.

ㆍTolerance ±20 microns

ㆍSticky liner

Packing

ㆍStandard roll size: Width 500 mm x Length 50 M / roll

ㆍMinimum Order Quantity: 200 M / color

ㆍPacking: 1 roll per 1 box

ㆍBox size: 153 mm x 158 mm x 524 mm

ㆍGross weight: approx. 7.54 kg / roll

* Other dimensions or special packing are available on request.

ㆍMinimum Order Quantity: 200 M / color

ㆍPacking: 1 roll per 1 box

ㆍBox size: 153 mm x 158 mm x 524 mm

ㆍGross weight: approx. 7.54 kg / roll

* Other dimensions or special packing are available on request.

Storage Conditions

ㆍTemperature: less than 25℃(± 5℃)

ㆍRelative Humidity: 50% (±15℃)

ㆍKeep out of direct sunlight

ㆍRelative Humidity: 50% (±15℃)

ㆍKeep out of direct sunlight

How To Use One Print

Print and cut directly onto the inside face of the film.

Let the printed design be completely dry. Dae Ha Printable media do not require a long drying time.

Weed the exceeding material.

Use DAE HA Application tape to transfer your design to the garment.

Ensure there are no air bubbles between your transfer and application tape.

Set the heat press to 150°C.

Apply medium and even pressure across the transfer.

Apply medium and even pressure across the transfer.

Peel the PET liner when it is warm.

Company Overview

Dae Ha Co., Ltd. is a leading manufacturer of Heat Transfer Flex in Korea and have been in the film business since 1986.

We are providing quality HTV products to our customers all over the world and the quality of our products are comparable with the leading company in this filed.

At the forefront of HTV technology since 1986, Dae Ha HTV supplies globally to distributors and other manufacturers with the USA our largest market, followed by Asia, and the Americas, together with major fashion and sportswear clothing manufacturers, with expansion in Europe now our main focus area.

With a large range of HTV and Sublimation Films, currently standing at over 300 unique colors and patterns, we continually invest in HTV Research and Development, with new and innovative products regularly brought on stream, while also frequently expanding colors and patterns in current ranges too.

Manufactured using high performance materials in Class 1,000 Clean Room facilities, our extensive color range of Heat Transfer Vinyl are consistently easy to weed and heat press, while offering superb wash durability.

We are very proud to introduce a world first in our industry, Recycled Blended Polyester into all our Heat Transfer Vinyl PET liners, supported by certification from Control Union. Investment will continue as we strive for breakthrough technology that allows us to become the first manufacturer t produce 100% sustainable and recyclable HTV.

Our production facilities hold the internationally acclaimed ISO 14001:2015 Environmental Management System, and we use only 100% recyclable and or biodegradable packaging or re-purposed packaging. We will ensure your weeded Dae Ha HTV and PET Liner will be turned into energy, and not into landfill, when returned to us.

We are providing quality HTV products to our customers all over the world and the quality of our products are comparable with the leading company in this filed.

At the forefront of HTV technology since 1986, Dae Ha HTV supplies globally to distributors and other manufacturers with the USA our largest market, followed by Asia, and the Americas, together with major fashion and sportswear clothing manufacturers, with expansion in Europe now our main focus area.

With a large range of HTV and Sublimation Films, currently standing at over 300 unique colors and patterns, we continually invest in HTV Research and Development, with new and innovative products regularly brought on stream, while also frequently expanding colors and patterns in current ranges too.

Manufactured using high performance materials in Class 1,000 Clean Room facilities, our extensive color range of Heat Transfer Vinyl are consistently easy to weed and heat press, while offering superb wash durability.

We are very proud to introduce a world first in our industry, Recycled Blended Polyester into all our Heat Transfer Vinyl PET liners, supported by certification from Control Union. Investment will continue as we strive for breakthrough technology that allows us to become the first manufacturer t produce 100% sustainable and recyclable HTV.

Our production facilities hold the internationally acclaimed ISO 14001:2015 Environmental Management System, and we use only 100% recyclable and or biodegradable packaging or re-purposed packaging. We will ensure your weeded Dae Ha HTV and PET Liner will be turned into energy, and not into landfill, when returned to us.

Other Products

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : Kelly Park

SHIPPING

Shipping from :

Republic of Korea

- 499 Gangseo-ro, Gangseo-gu, Seoul (07523)

Dae Ha Co., Ltd.

The person in charge

Donald KimAddress

499 Gangseo-ro, Gangseo-gu, Seoul (07523)

DAE HA

Dae Ha Co., Ltd.

Introduction

Dae Ha Co., Ltd. is a renowned manufacturer and global supplier of quality Heat Transfer Vinyl and DTF Film based in Korea. As a leading company in the field, we are dedicated to providing high quality products to our valued customers worldwide.

Manufactured using high performance materials in Class 1,000 Clean Room facilities, our extensive color range of Heat Transfer Vinyl and the quality DTF Film are consistently easy to weed and heat press, while offering superb wash durability.

Through an extensive nexwork of agents and distributors, we proudly export our products to customers across the globe. Dae Ha products are quite popular among customers with its premium quality, best prices and the good customer services.

At Dae Ha Co., Ltd., we take pride in being a trusted provider of quality Heat Transfer Vinyl and DTF Film, and we look forward to continuing to serve our customers with the utmost dedication and satisfaction.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Heat Transfer Flex, DH One Flex, Soft Plus, Glitter Flex, One Print, Puff PU, Flock Flex, Holographic Flex, Metallic Flex, PVC Flex, Reflective Flex, Shimmer Flex

-

- Established :

- 2015-07-28

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 5~10 people

R&D CERTIFICATE

-

- EN71

- SGS Korea Co., Ltd

- 2021.06.21

- 인증서보기

-

- EN71

- EN71

- 인증서보기

-

- EN71

- SGS

- 인증서보기

-

- SGS

- SGS

- 인증서보기

-

- LUX TEST

- 인증서보기

-

- CPSIA

- 인증서보기

-

- EN71

- 인증서보기

-

- OEKO-TEX

- 인증서보기

-

- SGS

- 인증서보기

-

- SGS

- SGS Korea Co., Ltd.

- 2019.05.07

- 인증서보기

-

- EN71

- SGS Korea Co., Ltd.

- 2021.05.18

- 인증서보기

-

- SGS

- SGS Korea Co., Ltd

- 2018.06.28

- 인증서보기

-

- EN71

- SGS Korea Co., Ltd

- 2021.05.18

- 인증서보기

-

- SGS

- SGS Korea Co., Ltd

- 2019.05.07

- 인증서보기

-

- REACH

- SGS Korea Co., Ltd

- 2019.05.07

- 인증서보기

-

- SGS

- SGS Korea Co., Ltd

- 2018.07.04

- 인증서보기

-

- EN71

- SGS Korea Co., Ltd

- 2021.05.21

- 인증서보기

-

- LUX TEST

- SGS Korea Co., Ltd

- 2016.08.29

- 인증서보기

-

- SGS

- SGS Korea Co., Ltd

- 2018.06.21

- 인증서보기

-

- SGS

- SGS Korea Co., Ltd

- 2018.06.26

- 인증서보기

-

- EN71

- SGS Korea Co., Ltd

- 2021.06.08

- 인증서보기

-

- Recycled Film_COC [RCS]

- Control Union Certification B.V.

- 2020.07.14

- 인증서보기

-

- ISO 9001

- IGC

- 2021.01.12

- 인증서보기

-

- ISO 1400

- IGC

- 2021.01.12

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 12,000

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- Dae Ha Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★