ITEM SPECIFICS

-

Brand

DNEO

-

origin

Republic of Korea

-

Size(Capacity)

25~6200

-

Condition

New

-

Features

Drum, Crane

PRODUCT DESCRIPTION

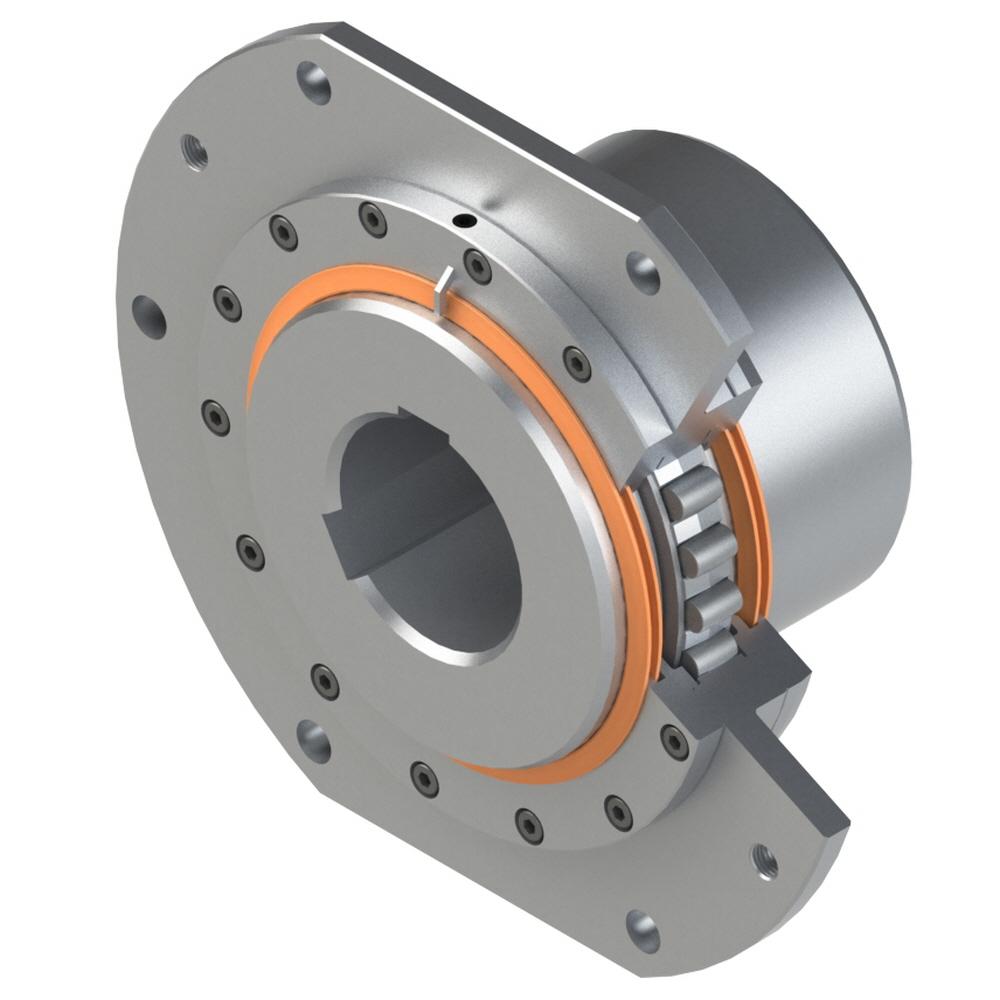

D'Neo Wire Drum Coupling is designed for installation in drum drive of crane or conveying systems.

This coupling can be used in the difficult and rough operating conditions associated with iron and steel work, or in the continuous heavy load operations of shore craned. It absorb press stress caused by the high torque and high radial loads resulting from the larger surface areas of these applications.

The design of this coupling prevents the danger of roller and bore breakage due to bending stress. The circular teeth on this coupling produces dramatically lower stress as compared to the bending stress involved with typical gear teeth.

The torque moment in the coupling is transmitted in two ways.

First, through the two drag faces of the sleeve which is housed in the drum.

Secondly, through a series of bolts which are fixed to the drum.

Wire Drum Coupling can compensate for angular mis alignments of up to 1° ,via a crown which allows the hub to oscillate with respect to the sleeve.

Depending on the size of the selected coupling, axial displacements from ±3mm up to ±8mm can be absorbed. Such couplings are not suitable for absorption or transmission of axial forces.

Feel free to contact me.

DNEO

Best Quality! Fast Delivery!

R&D CERTIFICATE

PAYMENTS DETAILS

- Mail Transfer : M/T

- Cash Against Document : CAD

- Name : LOUIS KIM

SHIPPING

- 257-27 Yulma-ro Tongjin-eup, Gimpo-si, Gyeonggi-do (10038)

D'NEO CO.,LTD

Seller_MailThe person in charge

CHANWOO KIMAddress

257-27 Yulma-ro Tongjin-eup, Gimpo-si, Gyeonggi-do (10038)

DNOQR

-

- Business Type :

- Manufacturer

-

- Main Product :

- TAPER GRID COUPLING, GEAR COUPLING, DISC COUPLING, ELASTOMERIC COUPLING

-

- Established :

- 2022-02-01

-

- Total Annual Revenue :

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- D'NEO CO.,LTD Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★