ITEM SPECIFICS

-

Brand

Model SSC, SECC seriesSHINFLEX

-

origin

Republic of Korea

-

Size(Capacity)

Link pitch: 65/95/125/130/180/250

-

Material

Steel+EGZ or Stainless

-

Function

No wear on cables and hoses

-

Features

Low maintenance requirements

-

age-appropriate

20~60

-

Gender

all

PRODUCT DESCRIPTION

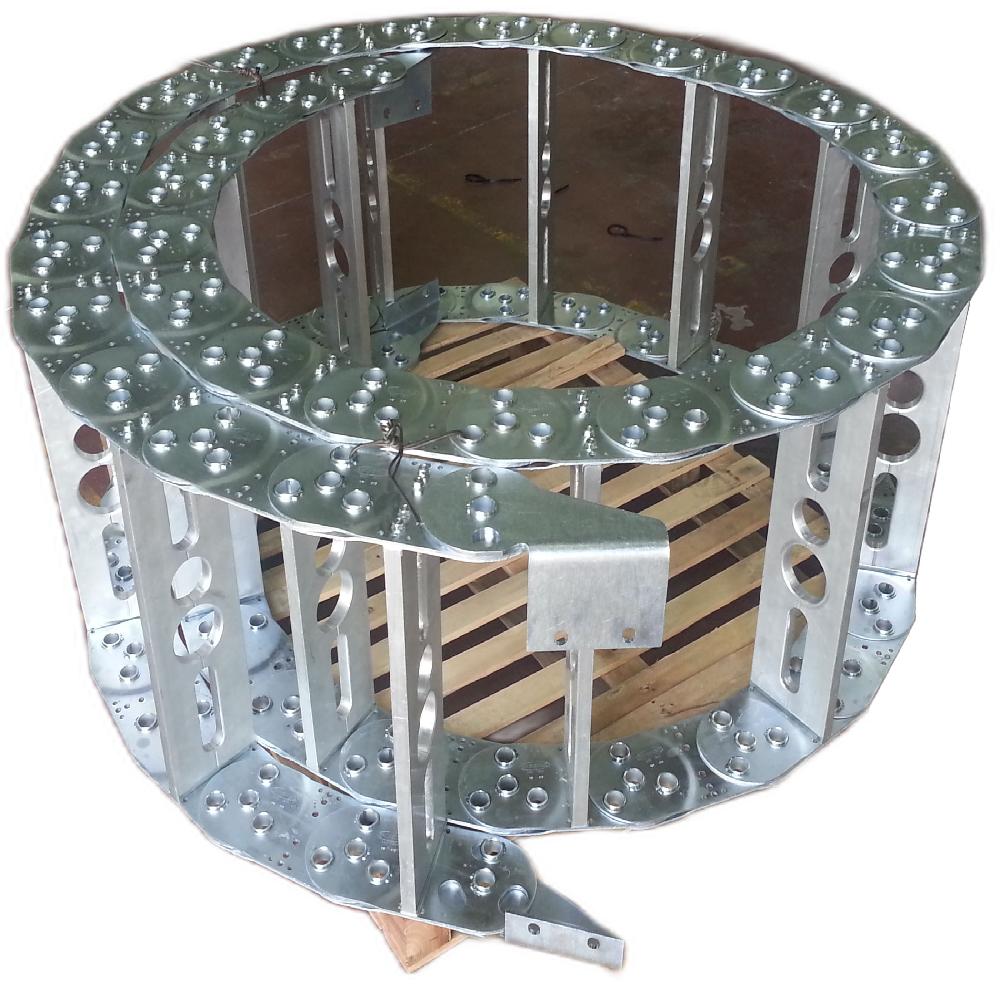

apparatus engineering, the automobile industry, in smelting plants and rolling mills, in materials-handing technology, in nuclear technology and in the offshore area, to name but a few branches: they have become a by-word in quality for optimalie careful-laying of supply lines. SHINSUNG drag chains act as a carrying, leading and protective element at one and the same time for all supply cables and hoses.

■ Assembly

SHINSUNG drag chains consist of two or more chain bands, running parallel to one another, and made of high grade, surface galvanized sheet steel. Chain bands of rust and acid resistant material available on request. The Chain bands are connected at intervals by stays. The stays, which can be supplied in various designs, take up the supply leads to be led in bore holes or opening. The drag chains are constructed in such a way that the curvature radius necessary in use is always guaranteed. The leads laid are thus not subject to any kind of mechanical stress. The chain joints block in the opposite direction. There are hardly any special structural requirements for connecting a SHINSUNG drag chain to mobile machinery.

SHINSUNG drag chains consist of two or more chain bands, running parallel to one another, and made of high grade, surface galvanized sheet steel. Chain bands of rust and acid resistant material available on request. The Chain bands are connected at intervals by stays. The stays, which can be supplied in various designs, take up the supply leads to be led in bore holes or opening. The drag chains are constructed in such a way that the curvature radius necessary in use is always guaranteed. The leads laid are thus not subject to any kind of mechanical stress. The chain joints block in the opposite direction. There are hardly any special structural requirements for connecting a SHINSUNG drag chain to mobile machinery.

■ Reasons for using SHINSUNG drag chains

��No wear on cables and hoses

��Long life of lines assured by protection from mechanical stress

��Avoidance of periods of disturbance and down time

��Little space required

��Simple assembly

��Low maintenance requirements

��Good visual improession

��Short delivery times for standard measurements

��No wear on cables and hoses

��Long life of lines assured by protection from mechanical stress

��Avoidance of periods of disturbance and down time

��Little space required

��Simple assembly

��Low maintenance requirements

��Good visual improession

��Short delivery times for standard measurements

※ To calculate a technical offer we need the following details:

��Number and outside diameter of the cables/hoses to be installed(with/without fittings)

��Weight of all cables and hoses including hose contents

��Mini. bending radius of cables/hoses acc. to manufacturer's specifications

��Length of travel mobile unit.

��Maximum acceleration/deceleration

��Speed of travel

��Frequency of travel

��Type of application drawing if possible

��Working environment

��Number and outside diameter of the cables/hoses to be installed(with/without fittings)

��Weight of all cables and hoses including hose contents

��Mini. bending radius of cables/hoses acc. to manufacturer's specifications

��Length of travel mobile unit.

��Maximum acceleration/deceleration

��Speed of travel

��Frequency of travel

��Type of application drawing if possible

��Working environment

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Manager

SHIPPING

Shipping from :

Republic of Korea

- 39 Jangansandan-ro Jangan-eup, Gijang-gun, Busan (46034)

SHINSUNG ELECTRIC CO., LTD.

The person in charge

KyungAe BangAddress

39 Jangansandan-ro Jangan-eup, Gijang-gun, Busan (46034)

SHINFLEX

SHINSUNG ELECTRIC CO., LTD.

Introduction

SHINSUNG Electric contributes to connect world , robot to people.

SHINSUNG Electric suggests clear direction of pioneering global market and maximizing

customer satisfaction by various projects as well as reliable Cable Carrier Chain with the

new development technology as a company to lead digital generation.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Cable carrier chain factory

-

- Established :

- 1987-01-20

-

- Total Annual Revenue :

- 4~5 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 4~5 billion (KRW)

-

- Total export revenue (previous year in USD)

- 54

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- SHINSUNG ELECTRIC CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★