- Health & Beauty Protective Items Health & Medical Beauty & Personal Care

- Bags, Shoes & Accessories Luggage, Bags & Cases Shoes & Accessories

- Apparel, Textiles & Accessories Apparel Textile & Leather Product Fashion Accessories Timepieces, Jewelry, Eyewear

- Electronics Industrial Computer & Accessories Home Appliance Consumer Electronic Security & Protection

- Electronic Equipment, Component & Telecoms Electronic Equipment & Supplies Telecommunication

- Home, Lights & Construction Construction & Real Estate Home & Garden Lights & Lighting Furniture

- Gifts, Sports & Toys Gifts & Crafts Toys & Hobbies Sports & Entertainment

- Agriculture & Food Agriculture Food & Beverage

- Auto & Transportation Automobiles & Motorcycles Transportation

- Machinery, Industrial Parts & Tools Machinery Industrial Parts & Fabrication Services Tools Hardware Measurement & Analysis Instruments

- Metallurgy, Chemicals, Rubber & Plastics Minerals & Metallurgy Chemicals Rubber & Plastics Energy Environment

- Packaging, Advertising & Office Packaging & Printing Office & School Supplies Service Equipment

- K-Service Innotech Contents ICT Technology/Engineering

- ETC ETC

Electrical power schematic automator (HESOFT - psA)

-

Payment

OT , T/T

-

MOQ

10 Not used

-

Supply Ability

100,000,000 Not used per One-Time

-

Supply Details

Customization Sample Order

Negotiable/ Depends on quantity / If you want to buy in bulk, please contact me.

-

Country of sale

World Wide, Asia, Europe, Americas, Middle East

-

PRICE

-

EXW

USD 7,000.00

(1 Not used)

-

ITEM SPECIFICS

-

Brand

Model HESOFT-psAHESOFT

-

origin

Republic of Korea

-

Size(Capacity)

200MB

-

Dimensions

CPU: quad core 3Ghz higher, GPU: Vram 4GB higher, Ram: 16GB higher, OS: Windows 10/11

-

Style

Electrical software

-

Function

Automatic generation of PLC electrical drawings

-

Features

Our technology supports standardization of drawings and data and informatization of know-how.

-

Condition

Software

-

Expiry Date

Warranty period: 1 year

PRODUCT DESCRIPTION

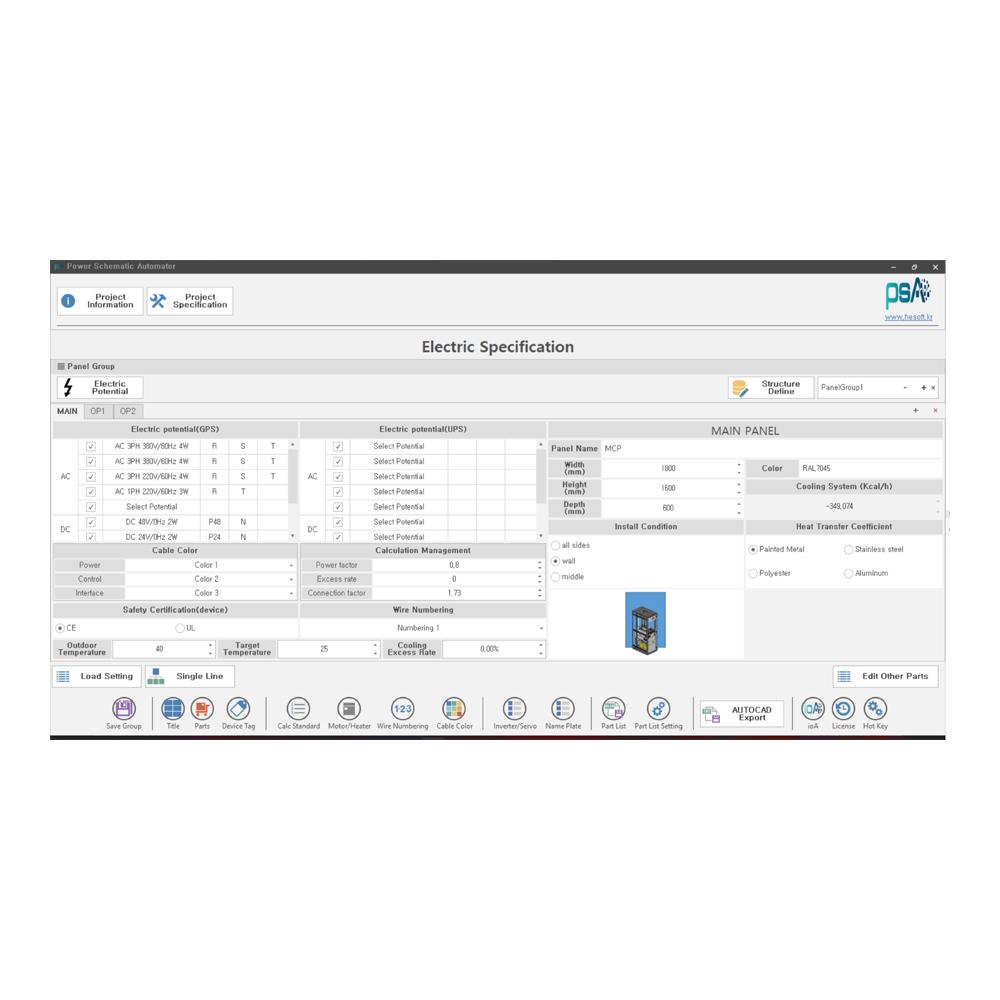

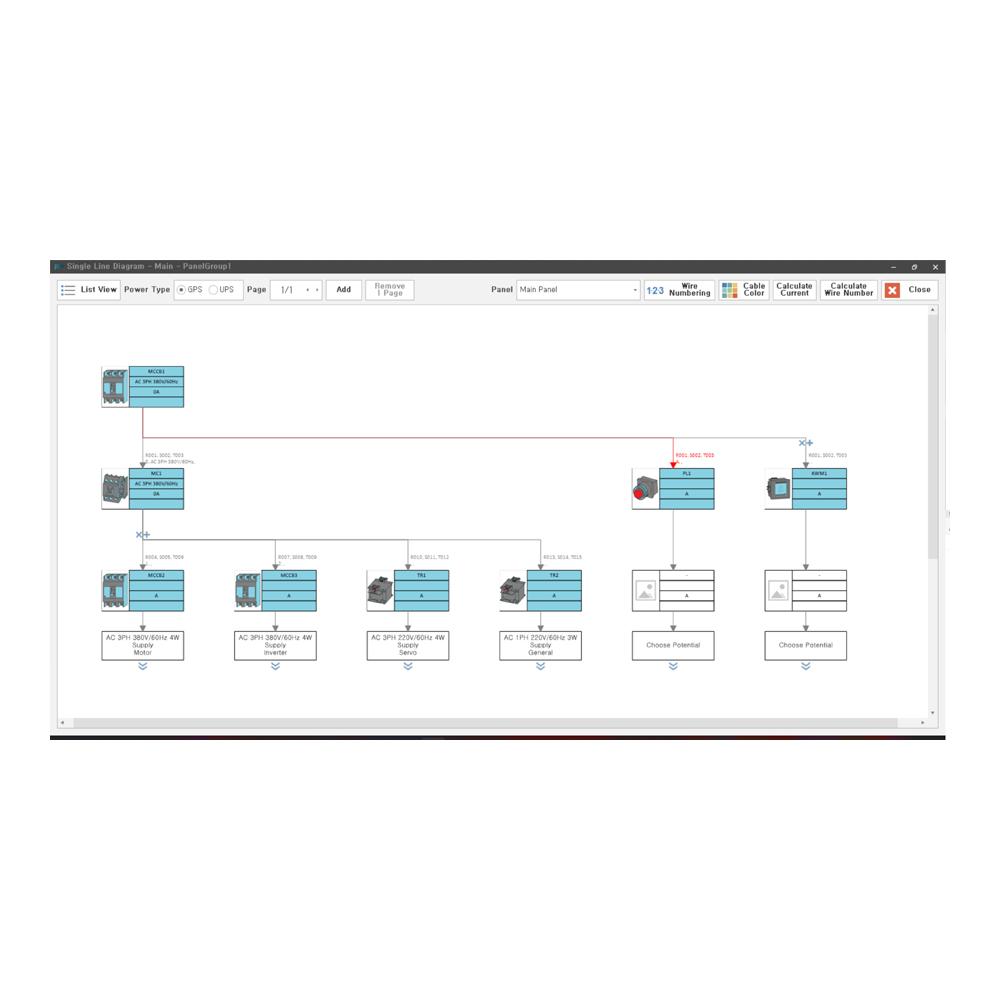

Electrical power schematic automator (HESOFT - psA)

Description

Power drawing and x-document automatic creation solution

Device selection and cable size are automatically entered according to the load capacity standard.

Line number is automatically entered and technical x-documents are automatically created.

Device selection and cable size are automatically entered according to the load capacity standard.

Line number is automatically entered and technical x-documents are automatically created.

Key Features

Drawing standardization is possible through automatic drawing.

• Automation solution that does not require separate development

• Finished product format with key part data

• Intuitive work method identical to traditional engineering work

• Supports expansion of parts data of various manufacturers

• Excel interface

• IEC/NFPA standard support

• Automation solution that does not require separate development

• Finished product format with key part data

• Intuitive work method identical to traditional engineering work

• Supports expansion of parts data of various manufacturers

• Excel interface

• IEC/NFPA standard support

Electrical design automation solution

What is HESOFT's Design Automation?

It is an efficient data-based design support solution that minimizes the designer's work and maximizes the reuse of existing data.

Reduction of design time by more than 80% of design process reduction, human error can be reduced to less than 5%, and x-document creation is supported.

What is HESOFT's Design Automation?

It is an efficient data-based design support solution that minimizes the designer's work and maximizes the reuse of existing data.

Reduction of design time by more than 80% of design process reduction, human error can be reduced to less than 5%, and x-document creation is supported.

Automation steps

ioA (PLC input/output drawing)

| Step01 | Step02 | Step03 | Step04 |

| PLC block diagram plan | Auto-generation of parts-based I/O | Import and automatically process Excel I/O Data | Automatic drawing - PLC configuration diagram - PLC detail drawing |

psA (power drawing)

| Step01 | Step02 | Step03 | Step04 |

| Input design specification | Select load type | Single line configuration - Automatic calculation of capacity - Automatic line number input - Part designation |

Automatic creation of drawings and x-documents - Automatic creation of single-line and multi-line diagrams - Automatic creation of production x-documents |

Improvement of innovative design method (generational change)

• A simple design tool that does not require additional training

• Increased utilization of new manpower

• Engineering know-how embedded (automatic calculation)

• Finished product form that does not require separate development

• 70% reduction in electrical design time

• Reduced error rate by 30% --> 5% compared to previous work

• Reverse engineering possible for equipment maintenance (facility --> drawing)

• Possible to produce customized drawings required by customers

• Automatic creation of production x-documents (Cover, table of contents, parts list, cable, terminal diagram, etc.)

• Support for 80% automation of electrical design work

• A simple design tool that does not require additional training

• Increased utilization of new manpower

• Engineering know-how embedded (automatic calculation)

• Finished product form that does not require separate development

• 70% reduction in electrical design time

• Reduced error rate by 30% --> 5% compared to previous work

• Reverse engineering possible for equipment maintenance (facility --> drawing)

• Possible to produce customized drawings required by customers

• Automatic creation of production x-documents (Cover, table of contents, parts list, cable, terminal diagram, etc.)

• Support for 80% automation of electrical design work

Introduction effect

• Supports efficient work performance by reducing business processes.

• Supports efficient work performance by reducing business processes.

The need for design automation

Low-quality drawings, non-standardized drawings, unnecessary time-consuming, additional cost loss

• Missing essential information with implicit drawing notation

• Difficult to maintain standards because each designer has a different writing method

• Causing communication problems between internal and external partners

• Inefficient working method due to graphic-based design

• Difficulty in recycling engineering data and informatizing companies

Low-quality drawings, non-standardized drawings, unnecessary time-consuming, additional cost loss

• Missing essential information with implicit drawing notation

• Difficult to maintain standards because each designer has a different writing method

• Causing communication problems between internal and external partners

• Inefficient working method due to graphic-based design

• Difficulty in recycling engineering data and informatizing companies

Company Overview

HESOFT has data-driven, automated electrical design technology.

We have a lot of experience in the field of electrical drawing standardization and automation technology.

The recently developed power drawing design automation solution can be integrated with PLC design automation software to accelerate the engineering design and manufacturing process.

Our technology supports standardization of drawings and data and informatization of know-how.

By recycling accumulated data, it shortens purchasing, design and manufacturing time, and maximizes production efficiency by utilizing it in maintenance work.

We have a lot of experience in the field of electrical drawing standardization and automation technology.

The recently developed power drawing design automation solution can be integrated with PLC design automation software to accelerate the engineering design and manufacturing process.

Our technology supports standardization of drawings and data and informatization of know-how.

By recycling accumulated data, it shortens purchasing, design and manufacturing time, and maximizes production efficiency by utilizing it in maintenance work.

Other Products

R&D CERTIFICATE

-

- Laboratory certificate

- Ministry of Science and ICT

- 2021.07.13

- 인증서보기

-

- Confirmation of venture company

- Venture company verification agency

- 2021.11.24

- 인증서보기

-

- Certificate of patent (No.10-2303625)

- Commissioner, Korean intellectual property office

- 2021.09.13

- 인증서보기

-

- Certificate of patent (No.10-2038092)

- Commissioner, Korean intellectual property office

- 2020.07.20

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- OT

- Telegraphic Transfer : T/T

- Name : Justin Kim

SHIPPING

Shipping from :

Republic of Korea

- 58 Yongmasan-ro 1-gil, Gwangjin-gu, Seoul (04930)

HESOFT

The person in charge

Justin KimAddress

58 Yongmasan-ro 1-gil, Gwangjin-gu, Seoul (04930)

HESOFT

HESOFT

Introduction

HESOFT has data-driven, automated electrical design technology.

We have a lot of experience in the field of electrical drawing standardization and automation technology.

The recently developed power drawing design automation solution can be integrated with PLC design automation software to accelerate the engineering design and manufacturing process.

Our technology supports standardization of drawings and data and informatization of know-how.

By recycling accumulated data, it shortens purchasing, design and manufacturing time, and maximizes production efficiency by utilizing it in maintenance work.

-

- Business Type :

- Knowledge Service

-

- Main Product :

- ioA, psA, PLC, automation,

-

- Established :

- 2017-03-15

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- Less than 5

R&D CERTIFICATE

-

- Laboratory certificate

- Ministry of Science and ICT

- 2021.07.13

- 인증서보기

-

- Confirmation of venture company

- Venture company verification agency

- 2021.11.24

- 인증서보기

-

- Certificate of patent (No.10-2303625)

- Commissioner, Korean intellectual property office

- 2021.09.13

- 인증서보기

-

- Certificate of patent (No.10-2038092)

- Commissioner, Korean intellectual property office

- 2020.07.20

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- HESOFT Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

How to

Use

How to

Use