RAY-EYE-MRT-R1

-

Payment

L/C(sight) , OT , T/T

-

MOQ

1 Set

-

Supply Ability

100 Set per One-Time

-

Supply Details

Customization Sample Order

please contact us for more options

-

Country of sale

Asia, Americas, Europe, Middle East, World Wide

-

PRICE

-

FOB

USD 7,200.00 ~ 7,300.00

(1 Set)

-

ITEM SPECIFICS

-

Brand

Model rem5000RAY-EYE

-

origin

Republic of Korea

-

Size(Capacity)

25*35*7 (Cm)

-

Package Includes

5,000g

-

Function

selects crack dimensions heat treatment defects for metal products.

-

Features

Non-contact measurements, measuring 8 frequencies simultaneously

-

Style

power supply used: AC 220 V, 60 Hz, 5A

-

Gender

all

PRODUCT DESCRIPTION

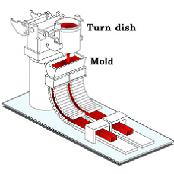

1. Equipment description RAY-EYE-MRT-R1 selects crack dimensions heat treatment defects for metal products. Magnetic Resonance Tester (MRT) device that compares the magnetic field impedance of a normal product and the magnetic field impedance of a defective product with BIG DATA and quickly and easily selects defects, dimensions, and heat treatment defects on the metal surface regardless of shape or size.

2. Field of application

- Metal (ferrous) product crack inspection, heat treatment inspection, illumination inspection

- Corrosion Under Insulation (CUI) inspection: Corrosion inspection in pipe

- Metal / Sintered Products Crack and Heat Treatment Inspection

- Inspect welding (secondary battery, bar welding)

- Metal (ferrous) product crack inspection, heat treatment inspection, illumination inspection

- Corrosion Under Insulation (CUI) inspection: Corrosion inspection in pipe

- Metal / Sintered Products Crack and Heat Treatment Inspection

- Inspect welding (secondary battery, bar welding)

3. Features

- Non-contact measurements, measuring 8 frequencies simultaneously

- Heat treatment determination NG/OK, Heat treatment depth determination NG/OK

- Display relative heat treatment hardness value/depth value after calibrating specimen

- Management of inspection results data

- Convenient UI configuration for non-professional use

- Non-contact measurements, measuring 8 frequencies simultaneously

- Heat treatment determination NG/OK, Heat treatment depth determination NG/OK

- Display relative heat treatment hardness value/depth value after calibrating specimen

- Management of inspection results data

- Convenient UI configuration for non-professional use

MRT – R1 Specification Sheet

1. Channel: 1ch to 8ch

2. Temperature of use: -10℃ to 40℃

3. Frequency of use: 1Hz to 3MHz, (low frequency: 1Hz unit adjustment, high frequency: 100Hz unit adjustment), 12V pp

4. Amplification degree control: 0 dB to 100 dB (1 dB Steps)

5. Inspection speed: 1 EA/Sec (shortest measurement 1EA 0.7 seconds)

6. Heat treatment setting: 0 calibration

7. Frequency: 8 Frequency

8. Separation distance: 0.7–10 mm

9. Filter: Use LPF and HPF simultaneously

10. S/W : MRT Inspection S/W

11. Sensor: Basic Surface and Penetration Sensor (Drive_Pickup Type)

12. Inspection history: Save inspection results/transmit data (Large HDD storage, USB backup/loadable)

13. Inspection ID setting: ID setting and storage for each type of inspection is possible

14.S/W Features and Remote Support:

- Remote support check for PC-connected equipment through remote software. Real-time AS support available

- Operate critical functions and set access restriction functions without changing them

15. Minimum defect size: Application of ASME code and special specification products

16. power supply used: AC 220 V, 60 Hz, 5A

2. Temperature of use: -10℃ to 40℃

3. Frequency of use: 1Hz to 3MHz, (low frequency: 1Hz unit adjustment, high frequency: 100Hz unit adjustment), 12V pp

4. Amplification degree control: 0 dB to 100 dB (1 dB Steps)

5. Inspection speed: 1 EA/Sec (shortest measurement 1EA 0.7 seconds)

6. Heat treatment setting: 0 calibration

7. Frequency: 8 Frequency

8. Separation distance: 0.7–10 mm

9. Filter: Use LPF and HPF simultaneously

10. S/W : MRT Inspection S/W

11. Sensor: Basic Surface and Penetration Sensor (Drive_Pickup Type)

12. Inspection history: Save inspection results/transmit data (Large HDD storage, USB backup/loadable)

13. Inspection ID setting: ID setting and storage for each type of inspection is possible

14.S/W Features and Remote Support:

- Remote support check for PC-connected equipment through remote software. Real-time AS support available

- Operate critical functions and set access restriction functions without changing them

15. Minimum defect size: Application of ASME code and special specification products

16. power supply used: AC 220 V, 60 Hz, 5A

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : Suh Dong Man

SHIPPING

Shipping from :

Republic of Korea

- 74 Hakhadong-ro, Yuseong-gu, Daejeon (34213)

Raynar Co., Ltd.

The person in charge

dongman suhAddress

74 Hakhadong-ro, Yuseong-gu, Daejeon (34213)

Introduction

Raynar has been developing and supplying equipment to industries based on R&D and field practice in the field of non-destructive testing for over 20 years.

We will do our best to help our customers achieve their dreams of zero defects by cultivating excellent talent and opening up equipment that uses sensing technology to find defects in various parts and materials.

We will do our best to develop non-destructive testing technology to become the world's best non-destructive testing equipment manufacturer advancing for the safety and happiness of mankind.

We will do our best to help our customers achieve their dreams of zero defects by cultivating excellent talent and opening up equipment that uses sensing technology to find defects in various parts and materials.

We will do our best to develop non-destructive testing technology to become the world's best non-destructive testing equipment manufacturer advancing for the safety and happiness of mankind.

-

- Business Type :

- Manufacturer

-

- Main Product :

- ECT, UT

-

- Established :

- 2002-04-01

-

- Total Annual Revenue :

- 1~2 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

TRADE EXPERIENCE

-

- Total revenue

- 1~2 billion (KRW)

-

- Total export revenue (previous year in USD)

- 3

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- Raynar Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★