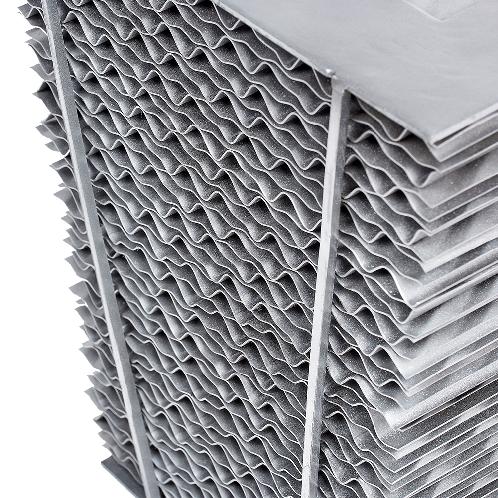

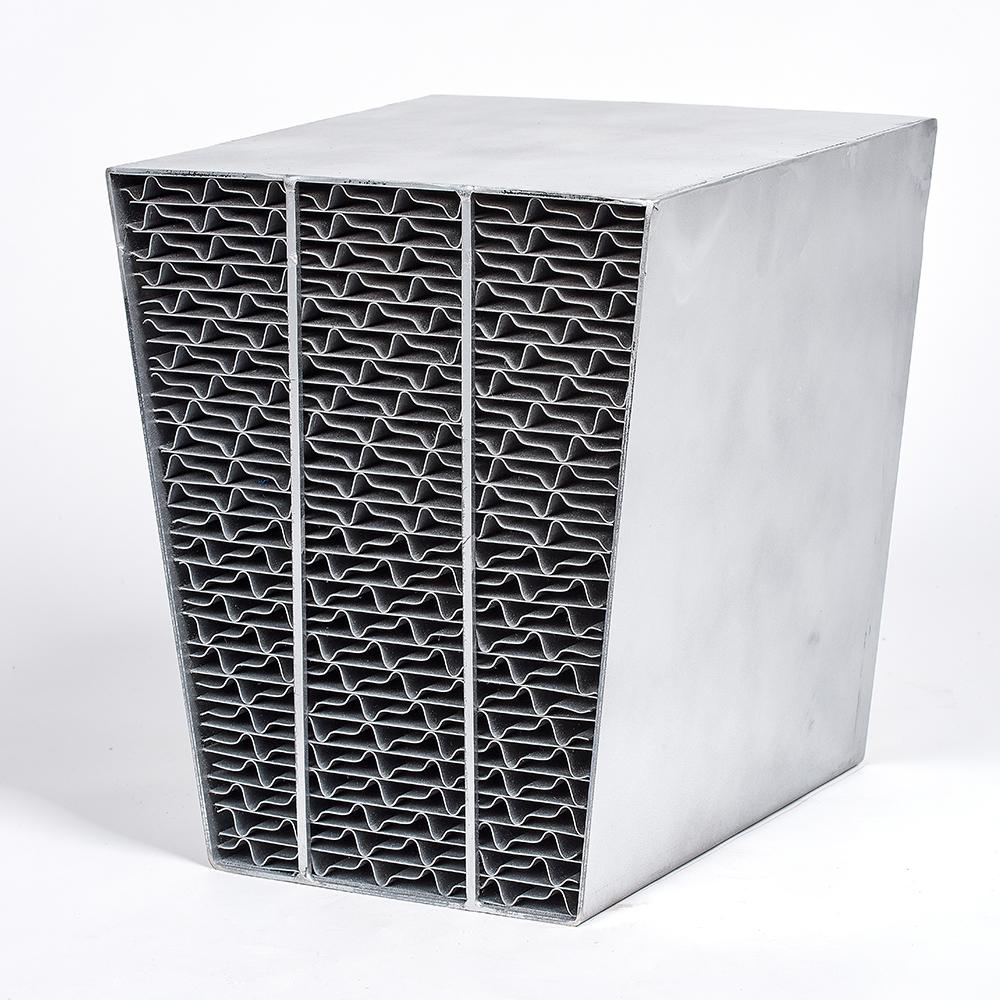

Heating Elements(Heat Exchanger) for Gas to Air Heater ( Air Heater )

-

Payment

L/C(sight)

-

MOQ

1 ea

-

Supply Ability

100,000 ea per One-Time

-

Supply Details

Customization

To be determined

-

Country of sale

World Wide, Asia, Middle East, Europe, Americas

-

PRICE

-

EXW

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model Air HeaterKOPEC

-

origin

Republic of Korea

-

Size(Capacity)

DTO

-

Function

Heat Exchanger and Heating Element for GAH(Air Preheater)

-

Material

DTO

-

Dimensions

DTO

-

Style

DTO

-

Condition

Heat exchanger bundle ( elements + basket )

-

Features

Porcelain Enamel Coating / Non-Coating

PRODUCT DESCRIPTION

Gas to Air Heater (GAH, Air Pre-Heater) installed for power generation efficiency is a device for heat exchange between the gas discharged from the boiler and the air entering the boiler, and metal heating elements are used.

However, these heating elements are clogged and corroded by sulfur oxides (SOx).

Therefore, KOPEC applies Porcelain Enamel coating to the thermal element to reduce clogging and make cleaning easier. Above all, it dramatically improves the corrosion resistance of the thermal element, thereby increasing the lifespan of the product.

However, these heating elements are clogged and corroded by sulfur oxides (SOx).

Therefore, KOPEC applies Porcelain Enamel coating to the thermal element to reduce clogging and make cleaning easier. Above all, it dramatically improves the corrosion resistance of the thermal element, thereby increasing the lifespan of the product.

∙ Product Name: Heating Element(heat exchanger) for GAH

∙ Brand Name: KOPEC

∙ Weight: DTO(Design to order)

∙ Height: DTO(Design to order)

∙ Width: DTO(Design to order)

∙ Origin: Korea

∙ Brand Name: KOPEC

∙ Weight: DTO(Design to order)

∙ Height: DTO(Design to order)

∙ Width: DTO(Design to order)

∙ Origin: Korea

Key Features

1. By applying Porcelain Enamel Coating, it is freed from the accumulation of foreign substances, and the lifespan of the product is increased.

2. Free from rust problem with organic coating.

3. Easy cleaning and increased operating efficiency

4. Satisfying various global standards

5. Direct production in KOPEC's factory in Republic of Korea

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Name : Seong Ho Seo

SHIPPING

Shipping from :

- 40 Bunseong-ro 569beon-gil, Gimhae-si, Gyeongsangnam-do (50820)

KOPEC Co., Ltd

The person in charge

Seong-Ho SeoAddress

40 Bunseong-ro 569beon-gil, Gimhae-si, Gyeongsangnam-do (50820)

Introduction

KOPEC is not only manufactures various type of Heat Exchangers, but also has the technology to apply Porcelain Enamel Coating to these with over 45 years of know-how. So that we improve the lifespan of products and achieve more eco-freindly power generation with power plants in Korea.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Heat Exchanger, Heating Elements, Air Preheater, Gas Heater

-

- Established :

- 1970-03-05

-

- Total Annual Revenue :

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- Patent 10-1175321

- Korean Intellectual property office

- Aug, 2012

- 인증서보기

-

- Patent 10-1956542

- Korean Intellectual property office

- Mar, 2019

- 인증서보기

-

- Inno-Biz

- Ministry of SME

- Aug, 2020

- 인증서보기

-

- EPC(Excellent Performance Certificate)

- Ministry of SME

- Aug, 2019

- 인증서보기

-

- Patent 10-2057233

- Korean Intellectual property office

- Dec, 2019

- 인증서보기

-

- Patent 10-2125655

- Korean Intellectual property office

- Jun, 2020

- 인증서보기

-

- Patent 10-2120028

- Korean Intellectual property office

- Jun, 2020

- 인증서보기

-

- Patent 10-2165439

- Korean Intellectual property office

- Oct. 2020

- 인증서보기

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items