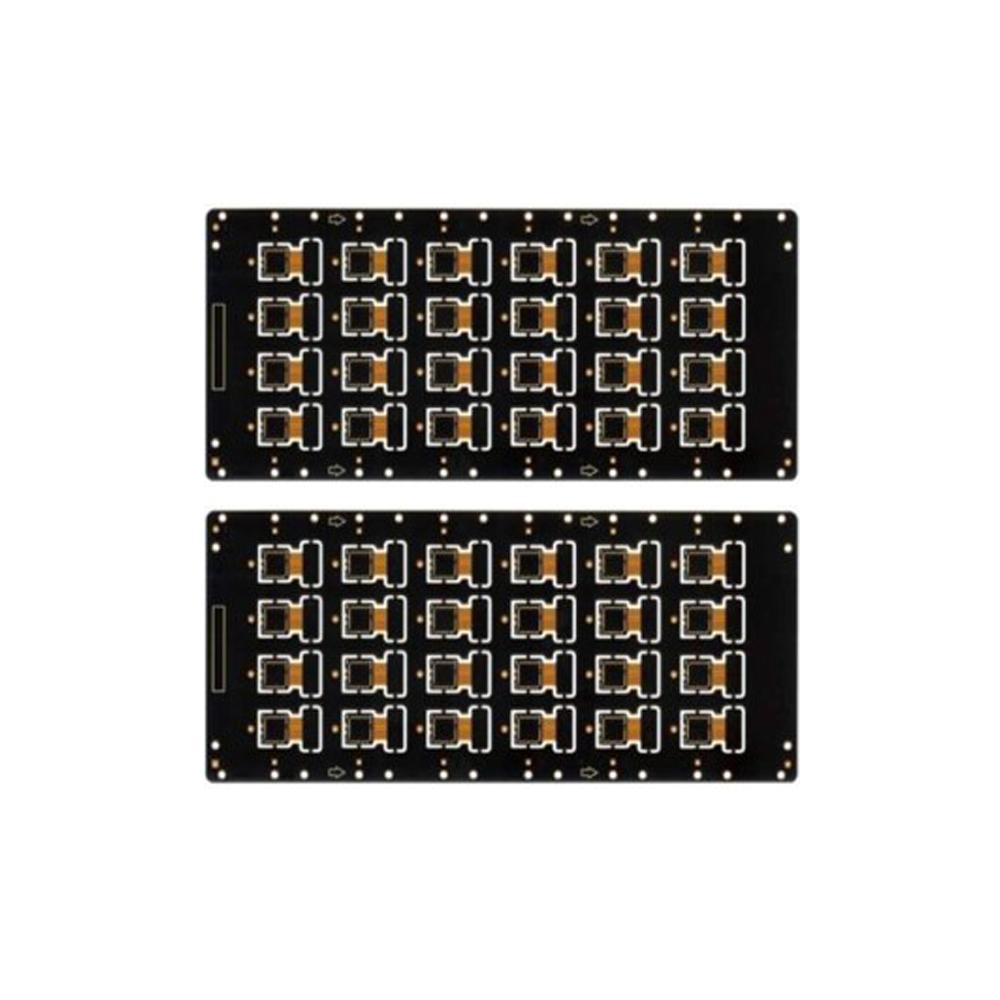

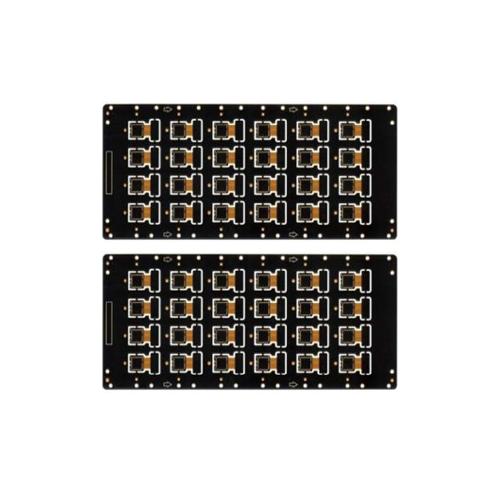

Camera Module Rigid Flexible manufacturing spec.

-

Payment

L/C(sight) , OT , T/T

-

MOQ

100 ea

-

Supply Ability

9,999,999,999 ea per One-Time

-

Supply Details

Customization Sample Order

Negotiable/ Depends on quantity / If you want to buy in bulk, please contact me.

-

Country of sale

Asia, Americas, Europe, Middle East, Africa

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model Camera ModuleMedical FPCB

-

origin

Republic of Korea

-

Size(Capacity)

Thickness 0.25T ~ 0.45T / Special :30㎛

-

Material

Film coating and resolution

-

Color

BLACK , BLUE , GREEN

-

Function

Rigid Flexible PCB, Printed circuit board

-

Features

Printed circuit board, PCB Prototype

-

Condition

Brand new

PRODUCT DESCRIPTION

Camera Module Rigid Flexible manufacturing spec.

Specification

| ITEM | SPEC. |

| PIXEL | 8M→13M→16M→20M |

| Flatness & Tilt | Special :30㎛ |

| Thickness | 0.25T ~ 0.45T |

| Structure | 2-3L DRILL, 1-2L, 3-4L BLIND VIA |

| Machine Drill | Min. 0.15mm |

| Laser Drill | BVH Min. 0.10mm |

| Cu Plating | 18[+-3㎛] / PTH or Via Fill |

| BGA PITCH | 0.4mm Under |

| x-layer | Rigid Flexible 4x-layer [4-2-4] / [4-2-2] |

| PSR | BLACK , BLUE , GREEN |

| Surface treatment | ENEPIG |

| Stiffner | PI , SUS |

| Other | EMI |

| Impedance | 100 Ω |

Description

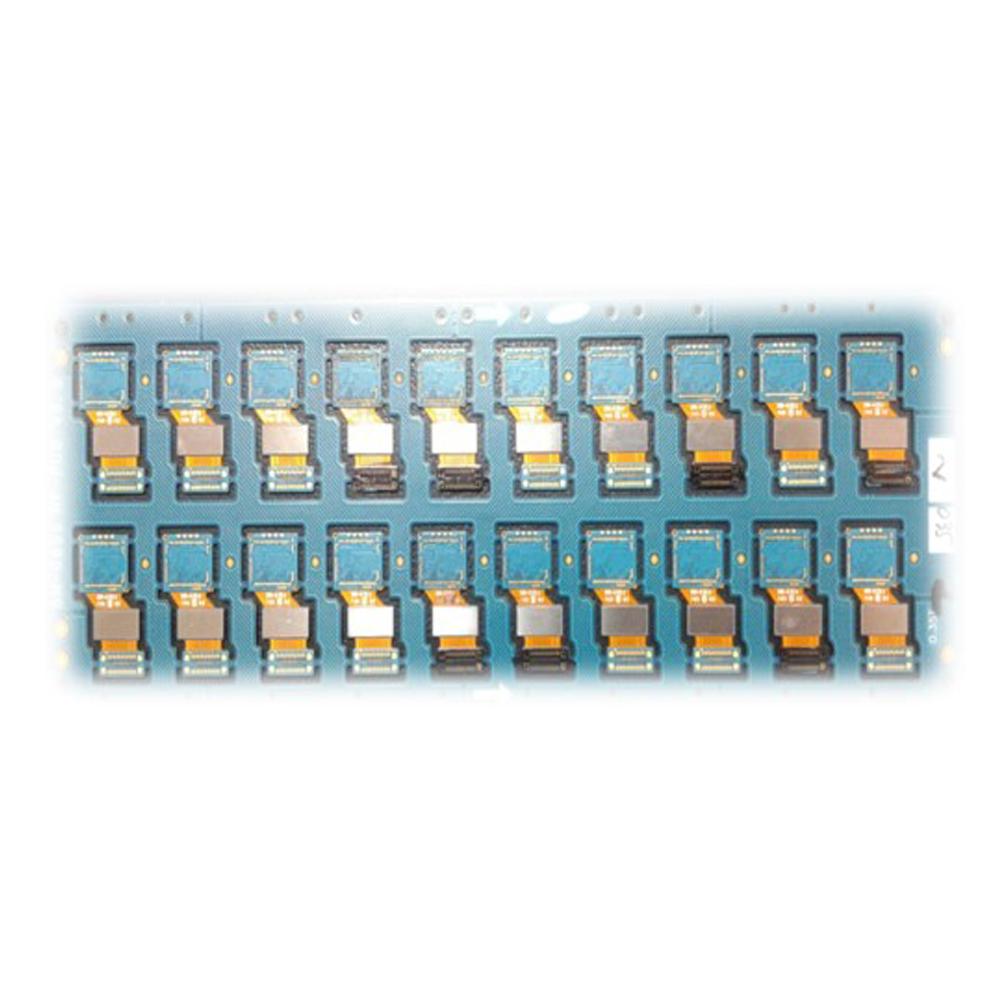

'Rigid-Flex circuit board is the advanced technology'

Design Capability

As printed circuit board technologies improve and electronics continue to get smaller and smaller, you need to make sure your current circuit board supplier has the appropriate equipment needed for the specialty processes that are found in more advanced circuit board designs. If your application requires a complex multi-x-layer board with fine lines and traces having plug via requirements, then we got you covered.

Our advanced multix-layer Rigid-Flex circuit technology allows for designers to sequentially add additional pairs of x-layers to form a multix-layer PCB up to 20 x-layers. JinSung Electronics has been very specialized and is a leading company over Rigid-Flex circuit globally, and we have supplied up to 20 x-layers R-Flex circuit boards to more than 50 customers since 2015.

The Rigid-Flex circuit board is a board consisting of a rigid part (non-bending part) and a flex part (bending part), and 3D circuit connection is possible by flexing the flex part. In addition, it has a bendability of up to 150,000 consecutive bends, and it is advantageous for miniaturization and weight reduction because there is no need for a connector for connection between modules.

In addition, it is possible to maximize the space utilization in the set with high design freedom, and a structural design with high density, thinness, and various floors is also possible.

Major application fields : Smartphones, tablets, laptops, wearables, display modules, camera modules, etc.

What core technology JinSung has for developing HDI circuit board?

What is the HDI PCB?

HDI PCB is the Abbreviation of high-density interconnect printed circuit board, a kind of printed circuit board manufacturing technology. An HDI PCB is a circuit board with a relatively high circuit density that uses micro-blind and buried "via"—or the copper-plated holes in PCBs—technology. HDIs are compact products designed for small-capacity users, as they cost much more than standard PCBs.

HDI PCB boards, one of the fastest growing technologies in the PCB industry, are now available at JinSung Electronics. HDI PCBs contain both the blind via and buried via hole varieties and have a higher circuitry density than traditional circuit boards.

What is the JinSung's capability to develop HDI PCB?

A microvia maintains a laser-drilled diameter of, typically, 0.006" (150µm), 0.005″ (125µm), or 0.004" (100µm), which are optically aligned and require a pad diameter of typically 0.012" (300µm), 0.010" (250µm), or 0.008" (200µm), allowing additional routing density. Microvias can be via-in-pad, offset, staggered or stacked, non-conductive filled and copper-plated over the top, or solid copper filled or plated. Microvias add value when routing out of fine-pitch ball grid arrays (BGAs) such as 0.8 mm pitch devices and below.

Additionally, microvias add value when routing out of a 0.5 mm pitch device where staggered microvias can be used. However, routing micro-BGAs such as a 0.4 mm, 0.3 mm, or 0.25 mm pitch device, requires the use of Stacked MicroVias using an inverted pyramid routing technique.

What are HDI PCB Advantages?

1. HDI technology can reduce the cost of PCB, although when the density of PCB increases beyond eight x-layers, it will be more expensive to manufacture with HDI.

2. Have better electrical performance and signal accuracy

3. Better reliability

4. Can improve thermal properties

5. Can improve radio frequency interference/electromagnetic wave interference/electrostatic discharge (RFI/EMI/ESD)

6. Greater design efficiency

Design Capability

As printed circuit board technologies improve and electronics continue to get smaller and smaller, you need to make sure your current circuit board supplier has the appropriate equipment needed for the specialty processes that are found in more advanced circuit board designs. If your application requires a complex multi-x-layer board with fine lines and traces having plug via requirements, then we got you covered.

Our advanced multix-layer Rigid-Flex circuit technology allows for designers to sequentially add additional pairs of x-layers to form a multix-layer PCB up to 20 x-layers. JinSung Electronics has been very specialized and is a leading company over Rigid-Flex circuit globally, and we have supplied up to 20 x-layers R-Flex circuit boards to more than 50 customers since 2015.

The Rigid-Flex circuit board is a board consisting of a rigid part (non-bending part) and a flex part (bending part), and 3D circuit connection is possible by flexing the flex part. In addition, it has a bendability of up to 150,000 consecutive bends, and it is advantageous for miniaturization and weight reduction because there is no need for a connector for connection between modules.

In addition, it is possible to maximize the space utilization in the set with high design freedom, and a structural design with high density, thinness, and various floors is also possible.

Major application fields : Smartphones, tablets, laptops, wearables, display modules, camera modules, etc.

What core technology JinSung has for developing HDI circuit board?

What is the HDI PCB?

HDI PCB is the Abbreviation of high-density interconnect printed circuit board, a kind of printed circuit board manufacturing technology. An HDI PCB is a circuit board with a relatively high circuit density that uses micro-blind and buried "via"—or the copper-plated holes in PCBs—technology. HDIs are compact products designed for small-capacity users, as they cost much more than standard PCBs.

HDI PCB boards, one of the fastest growing technologies in the PCB industry, are now available at JinSung Electronics. HDI PCBs contain both the blind via and buried via hole varieties and have a higher circuitry density than traditional circuit boards.

What is the JinSung's capability to develop HDI PCB?

A microvia maintains a laser-drilled diameter of, typically, 0.006" (150µm), 0.005″ (125µm), or 0.004" (100µm), which are optically aligned and require a pad diameter of typically 0.012" (300µm), 0.010" (250µm), or 0.008" (200µm), allowing additional routing density. Microvias can be via-in-pad, offset, staggered or stacked, non-conductive filled and copper-plated over the top, or solid copper filled or plated. Microvias add value when routing out of fine-pitch ball grid arrays (BGAs) such as 0.8 mm pitch devices and below.

Additionally, microvias add value when routing out of a 0.5 mm pitch device where staggered microvias can be used. However, routing micro-BGAs such as a 0.4 mm, 0.3 mm, or 0.25 mm pitch device, requires the use of Stacked MicroVias using an inverted pyramid routing technique.

What are HDI PCB Advantages?

1. HDI technology can reduce the cost of PCB, although when the density of PCB increases beyond eight x-layers, it will be more expensive to manufacture with HDI.

2. Have better electrical performance and signal accuracy

3. Better reliability

4. Can improve thermal properties

5. Can improve radio frequency interference/electromagnetic wave interference/electrostatic discharge (RFI/EMI/ESD)

6. Greater design efficiency

Certifications and Patents

Other Products

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : LIM KYU HYUK

SHIPPING

Shipping from :

Republic of Korea

- 275-10 Sinwon-ro Danwon-gu, Ansan-si, Gyeonggi-do (15602)

Jinsung Electronics Co., Ltd.

The person in charge

Kyu Hyuk LimAddress

275-10 Sinwon-ro Danwon-gu, Ansan-si, Gyeonggi-do (15602)

Jinsung El

Jinsung Electronics Co., Ltd.

Introduction

Since it's founding in 1995, Jinsung Electronics Co., Ltd. has been making company wide efforts to satisfy the needs of various customers through continuous development and research.

We are the first in Korea to develop and mass produce Rigid Flex PCB for camera modules and PCB for waterproof ear jacks for smart phone, and supply them exclusively to Samsung Electronics.

In additions, we supply high end Rigid Flex PCBs used in various product lines such as automobiles, medical equipment, military supplies to domestic and overseas markets.

Based on our unique technology and accumulated Know how, we are committed to growing as a global company.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Advanced and Unique Products

-

- Established :

- 1995-12-01

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- Jinsung Electronics Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

![Medical FPCB manufacturing spec. [FPCB S/S]](/image/goodsImage.do?goods_no=GS2022071314645&image_se_code=MAIN_THUMB174)

![Unbalance Rigid Flexible (FPCB+FR4) Double Side manufacturing spec. [FPCB S/S]](/image/goodsImage.do?goods_no=GS2022071314646&image_se_code=MAIN_THUMB174)