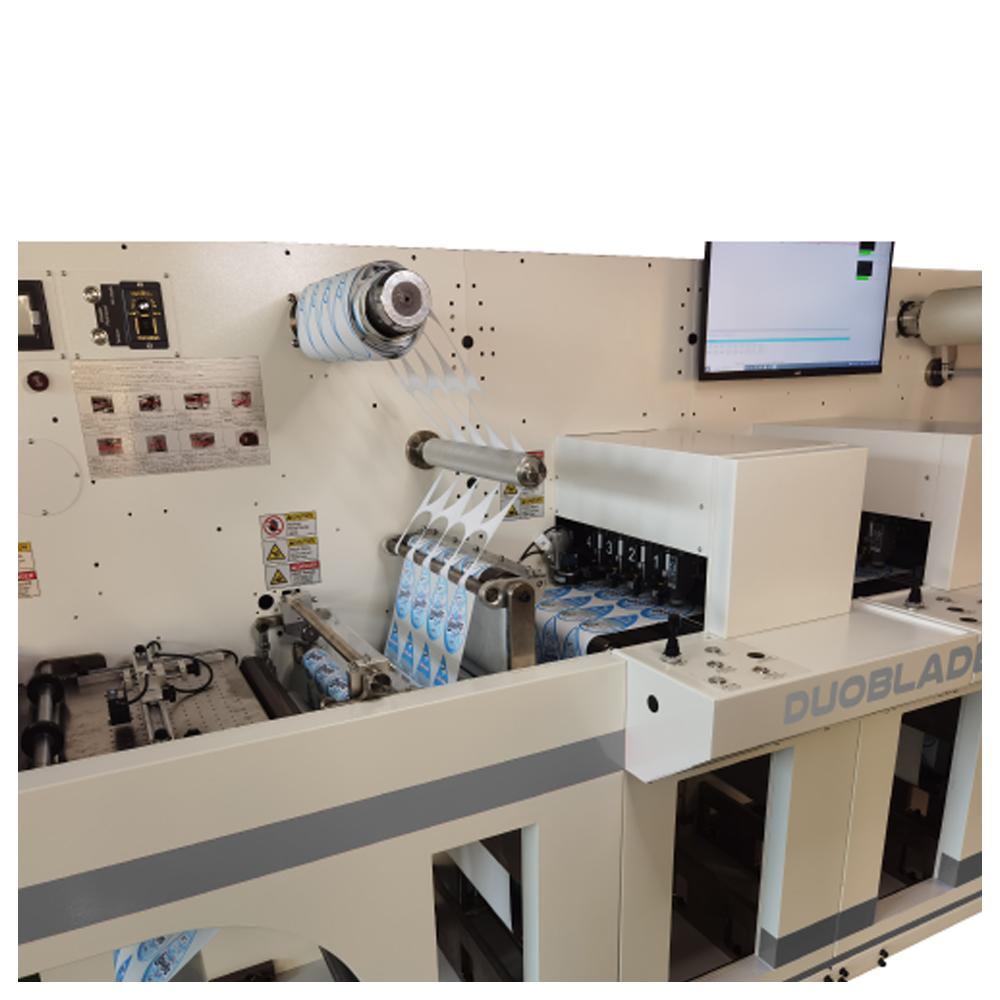

13 Inch Roll to Roll Digital Blade Finisher DUOBLADE WX II

-

Payment

OT , T/T

-

MOQ

1 Unit

-

Supply Ability

5 Unit per Month

-

Supply Details

Customization

Depend on quantity

-

Country of sale

Asia, Americas, Europe, World Wide, Middle East

-

PRICE

-

EXW

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model DUOBLADE WX IIZAGAR

-

origin

China

-

Size(Capacity)

251cm(L) x 130cm(W) x 164cm(H)

-

Weight

1200kg

-

Function

Roll to roll digital label finisher

PRODUCT DESCRIPTION

13 Inch Roll to Roll Digital Blade Finisher DUOBLADE WX II

PRODUCTIVITY PROMISING SMART ROLL LABEL FINISHER DUOBLADE WXII

DOUBLE STATION, DOUBLE SPEED. NO MORE LASER CUTTER.

DUOBLADE WX II satisfies most of all various branded digital label presses for die cutting, slitting, laminating, waste removal, separating in rolls or sheets

with high level of automation and inteligent job changing in superb quality and speed.

DUOBLADE WX II satisfies most of all various branded digital label presses for die cutting, slitting, laminating, waste removal, separating in rolls or sheets

with high level of automation and inteligent job changing in superb quality and speed.

QUALITY

▶Knife does not leave burnt marks or swollen edges.

▶Nothing scratches paper surface or backliner at all.

▶Real time auto-correction of registration by CCD

▶Knife does not leave burnt marks or swollen edges.

▶Nothing scratches paper surface or backliner at all.

▶Real time auto-correction of registration by CCD

SPEED

▶Fast mark sensing does not delay the cutting process.

▶8 cutting heads in 2 stations maximize production rate.

▶18m/min speed achievable for 10cm x 10cm rectangles

▶Fast mark sensing does not delay the cutting process.

▶8 cutting heads in 2 stations maximize production rate.

▶18m/min speed achievable for 10cm x 10cm rectangles

ALL IN ONE

▶Lami, die-cut, waste removal, slit, strip, sheet cut

▶Up / down separate rewinding and sheet cutter

▶Penumatic tension control for every roller and bar

▶Lami, die-cut, waste removal, slit, strip, sheet cut

▶Up / down separate rewinding and sheet cutter

▶Penumatic tension control for every roller and bar

AUTOMATION

▶Controlled by embedded PC with large LCD monotor

▶Automatic job change by reading job code by CCD

▶Optimized use of selective heads by auto gap control

▶Working time estimation for the selected job amount

▶Controlled by embedded PC with large LCD monotor

▶Automatic job change by reading job code by CCD

▶Optimized use of selective heads by auto gap control

▶Working time estimation for the selected job amount

| PRODUCTIVITY PROMISING 2 stations of DUOBLADE WX II can cut the same shapes in different columns or different shapes in the same column for separate rewinding of each row independently. |

|

| TRAJECTORY OPTIMIZATION DUOBLADE WX II finds optimal way of cutting by itself for different jobs. When cutting 5 rows for example, it uses 4 heads in the first step and 1st head cuts the last row in second step. Starting point and sequence of cutting can be automatically optimized together as well. |

|

| AUTOMATIC JOB CHANGE Artificial intelligence algorithm in DUOBLADE WX II gives you the highest level of automation in processing different jobs together. According to the recognized job by reading job code using CCD camera, all settings and gaps between heads can be adjusted for itself. |

SPECIFICATION

| Max. Roll Diameter | 450mm | Cutting Accuracy | ±0.05mm |

| Media Width | min. 100 ~ max. 350mm | Job Code Format | Numatical job code (0000~9999) |

| Max. Label Size | 330mm x 600mm | Sensors | CCD Camera, B/W sensor and RGB sensor |

| Tension Control System | 6-axis automatic pneumatic control | Machine Dimension | 251cm(L) x 130cm(W) x 164cm(H) |

| Cutting Speed | Avg. 15~18 m/min, Max. 20~25 m/min | Machine Weight | 1500 kgs (1650kgs after packing) |

| No. of Cutting Heads | Total 8 cutting heads (4 / station) | Electric / Air Source | 100~240V 1Ø AC, 2000W, 0.4 bar |

| Slitting Module | 4 as default (Max. 15 units installable) | Available Options | Sheet cutter, Up rewinder, Laminating film backliner rewinder, additional slitters |

| Web Guide | German BST brand(ultrasolic system) | Warranty | 13 months after shipment |

Other Products

R&D CERTIFICATE

-

- CE

- UDEM

- 01.06.2015

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- OT

- Telegraphic Transfer : T/T

- Name : Park Se Mi

SHIPPING

Shipping from :

Republic of Korea

- 127 Beobwon-ro (05836)

- Air Cargo : Please contact us for inquiry on carriers

- Sea Freight : Please contact us for carriers inquiry

- Land Transportation

- Sea Freight : impossible

- Please contact your administrator for detailed information.

- Name : Se Mi,Park

- Tel : 82-2-6082-5022

Valloy Incorporation

The person in charge

Juan KimAddress

127 Beobwon-ro, Songpa-gu, Seoul (05836)

VALLOY

Valloy Incorporation

Introduction

VALLOY INC. is an international marketing and publishing company for various products and solutions in visualization and digital printing market. VALLOY Inc. is Korean Venture company established in July, 2004. The company has founded by international marketing professionals and digital imaging professionals who have tens of year experience in development and marketing for various digital printing solutions including software, imaging devices, machinery, assemblies,consumables, substrates and next dimensional displays in signage printing, textile printing, interior decoration and label & packaging market. Industrial market like printed electronics or bio-cell printing is another opportunity for digital production by inkjet technology.

VALLOY means Value Alloyers, aiming value of synergy in different people and technologies in digital printing industry. We will provide most demanding products in the market based on in-depth market research that we are conducting in the worldwide market through the vast network of experienced and prestigious partners, to grow together with our customers.

VALLOY means Value Alloyers, aiming value of synergy in different people and technologies in digital printing industry.

We will provide most demanding products in the market based on in-depth market research that we are conducting in the worldwide market through the vast network of experienced and prestigious partners, to grow together with our customers.

-

- Business Type :

- Manufacturer

-

- Main Product :

- DUOBLADE PETTI

-

- Established :

- 2004-07-15

-

- Total Annual Revenue :

- 1~2 billion (KRW)

-

- Total Employees :

- 5~10 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 1~2 billion (KRW)

-

- Total export revenue (previous year in USD)

- 1,083

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- Valloy Incorporation Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★