ITEM SPECIFICS

-

Brand

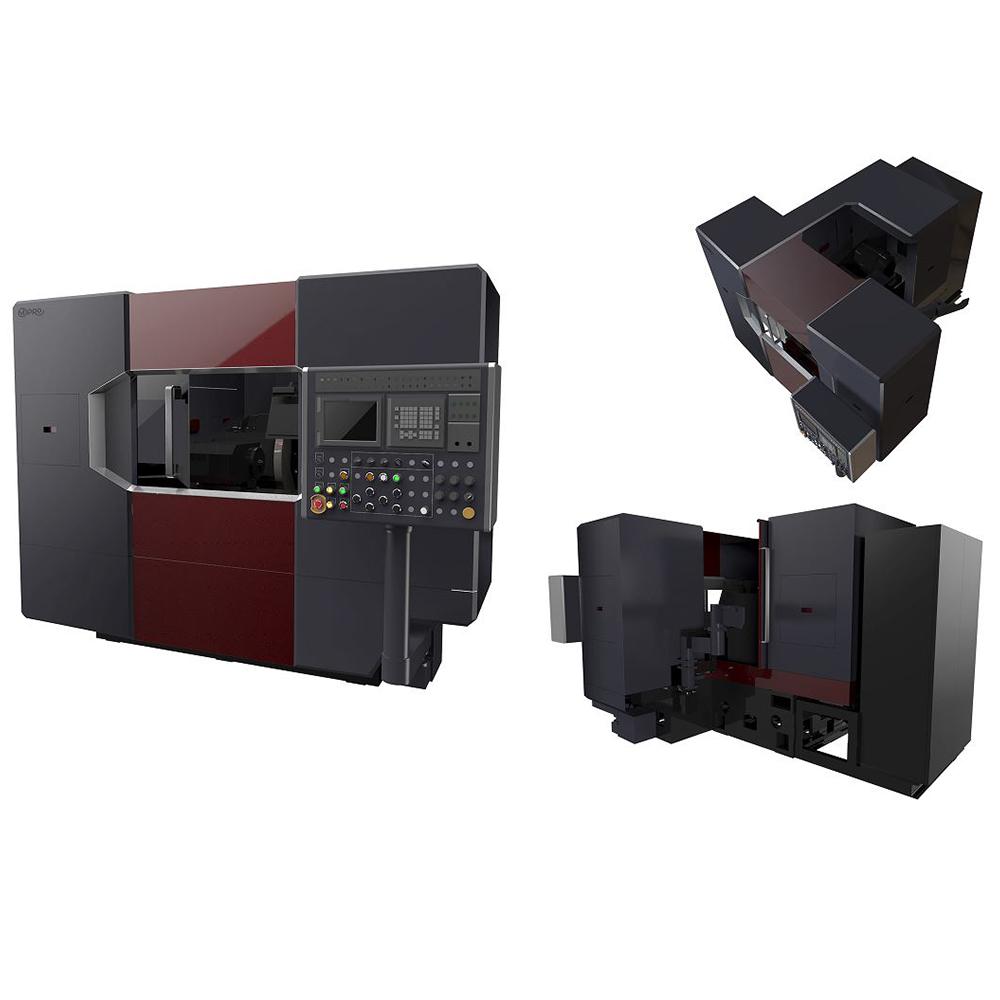

Model AH1-304f / CH1-304fMPRO

-

origin

Republic of Korea

-

Size(Capacity)

SwingΦ240, Center Dist. 400mm

-

Weight

7.5~8.2 ton

-

Dimensions

2700 x 3000

PRODUCT DESCRIPTION

This Angular Grinding Machine features grinding-processes that simultaneously grind the external circumference-face and section-face of an object by stroking grinding wheel in a perpendicular direction.

(In the case of a Cylindrical Grinding Machine, its grinding processes covers only the external circumference-face by stroking grinding wheel by perpendicular direction.)

And this machine series is being supplied to production lines of large automobile manufacturers.

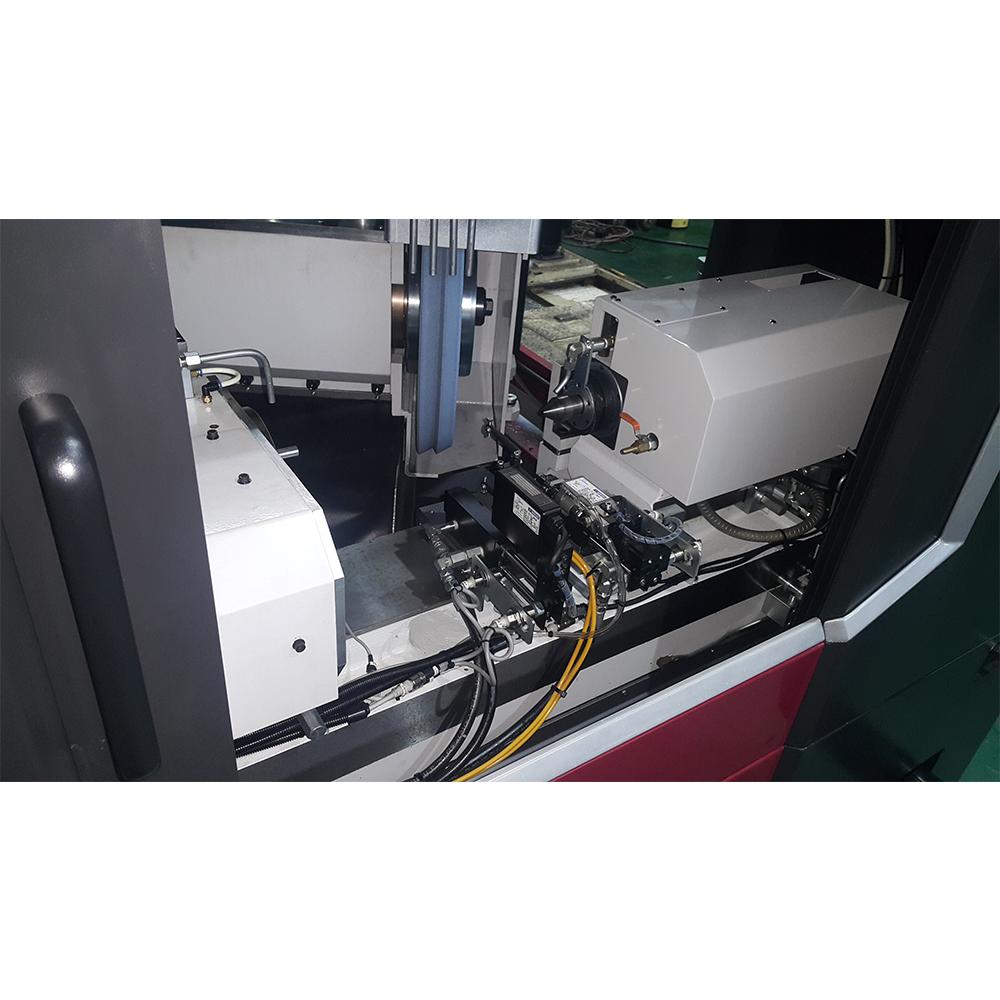

The machine has high-level specifications required in the production line through several mechanisms such as forced lubrication of the slide surface on the spindle table base, and hydrostatic lubrication for the wheel spindle,

with a separated lubrication unit connected through filters/ flow switches / pressure switches for supplying lub-oil, For bearings of the spindle unit, hydrostatic metals are fitted on the wheel side, pulley side, and thrust side,

so that those oil-pressures complete levitation to make a centering spindle.

The mounted spindle has high stiffness and precise spinning performance by applying heat treatment and super-finishing.

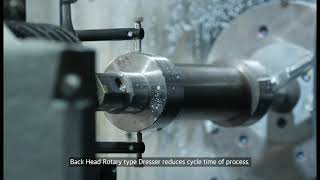

Also a Back Head type's Templateless CNC Rotary Dressing unit is applied to the advanced model by the CNC program controlling diamond tool.

MPROGrinding Machine series are designed, fabricated, thoroughly inspected, and tested directly by our own engineers.

Hereby, through our own R&D, the supplied machines are acknowledged for improved operability and convenience in maintenance which are better than those of other makers'.

R&D CERTIFICATE

-

- KCs

- KOSHA

- 20210121

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Name : PARK HYOGA

SHIPPING

Shipping from :

Republic of Korea

- 5537-8 Saneop-ro Gangdong-myeon, Gyeongju-si, Gyeongsangbuk-do (38032)

CHEIL C&M Co.,Ltd

The person in charge

Hyoka ParkAddress

5537-8 Saneop-ro Gangdong-myeon, Gyeongju-si, Gyeongsangbuk-do (38032)

HOMEPAGE

CHEIL C&M Co.,Ltd

Introduction

Cheil E&M (hereafter, "Cheil") was established in 2003 by a group of talented people who were engaged with decades of technical know-how in machine tools, and has been managing decades of machine tool remodeling, overhauling, and new building up machine tools.

For the perfection of these services, Cheil has the capability to carry out all processes of mechanical design, electrical design, equipment assembly and try-out, hereby Cheil has been providing its services and new equipments to the industries who needs various machine tools.

The technology of Cheil is approved by many conglomerates in Korea, therefore as a primary vendor, Cheil is involved in many mass-production facilities & lines in automobiles, steel, and heavy industries, and meets various demands by own eminent technical capabilities.

Currently, Cheil's services & machines are being delivered not only domestically (Korea), but also to the United States, India, Indonesia, and China.

Also Cheil proceeds research and development to reinforce the lineup of MPRO™ grinding machines and especially is looking for partners to meet wider demand of grinding machine.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Grinding Machine

-

- Established :

- 2003-09-15

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- KCs

- KOSHA

- 20210121

- 인증서보기

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 3,229

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- CHEIL C&M Co.,Ltd Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★