High Performance Carbide End Mills

-

Payment

L/C(sight) , OT , T/T

-

MOQ

100 Set

-

Supply Ability

10,000 Set per One-Time

-

Supply Details

Customization Sample Order

Negotiable

-

Country of sale

Asia, Americas, Europe, Middle East, World Wide

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model COGO TOOLCOGO TOOL

-

origin

Republic of Korea

-

Size(Capacity)

Various

-

Function

having pushed on the field of carbide cutting tools to make carbide end mills

-

Style

special coating process for maximizing anti-abrasion

-

Features

show the excellent performance of high speed and efficiency

-

Weight

Various

PRODUCT DESCRIPTION

High Performance Carbide End Mills

[Definition of end mill]

What is an end mill?

It is defined as a shank type milling cutter that has a cutting edge on the outer surface and cross-section. An end mill is a tool that rotates and shaves the sides and top surface of a processed item with an outer blade and a bottom blade of a cross-section, respectively. End mills are especially used in precision processing of electrical, electronic and automotive parts and molds.

Selection of end mill

The performance of an end mill varies depending on the settings such as the number of blades, twist angle, inclination angle, relief angle and coating type, and a suitable shape is required for high-speed cutting operations.

The main part details of End mills

It is defined as a shank type milling cutter that has a cutting edge on the outer surface and cross-section. An end mill is a tool that rotates and shaves the sides and top surface of a processed item with an outer blade and a bottom blade of a cross-section, respectively. End mills are especially used in precision processing of electrical, electronic and automotive parts and molds.

Selection of end mill

The performance of an end mill varies depending on the settings such as the number of blades, twist angle, inclination angle, relief angle and coating type, and a suitable shape is required for high-speed cutting operations.

The main part details of End mills

[Specification]

| Series | EDP.NO | Flutes | Type |

| K CBN |

2CRB | 2 Flutes | CBN Ball End Mills |

| 2CCR | 2 Flutes | CBN Corner Radius | |

| K SPEED |

2SRB | 2 Flutes | Rib Ball End Mills |

| 2SRE | 2 Flutes | Rib End Mills | |

| 4SRB | 4 Flutes | Rib End Mills | |

| 2TBE | 2 Flutes | Taper Neck Ball End Mills | |

| 2DPH | 2 Flutes | End Mills for 3D Cut 230˚ | |

| 4DPH | 4 Flutes | End Mills for 3D Cut 230˚ | |

| 4DPM | 4 Flutes | End Mills for 3D Cut 270˚ | |

| 2TCR | 2 Flutes | Taper Neck corner Radius | |

| 4TCR | 4 Flutes | Taper Neck corner Radius | |

| 2UPB | 2 Flutes | Ultra Precision Ball End Mills | |

| 2SCB | 2 Flutes | Standard Ball End Mills | |

| 3SCB | 3 Flutes | Standard Ball End Mills | |

| 4SCB | 4 Flutes | Standard Ball End Mills | |

| 2SCE | 2 Flutes | Standard End Mills | |

| 4SCE | 4 Flutes | Standard End Mills | |

| 4SEM | 4 Flutes | 45˚Helix End Mills | |

| 4&8SEM | 4&8Flutes | 45˚Helix End Mills | |

| 2RCR | 2 Flutes | Rib Corner Radius | |

| 4RCR | 4 Flutes | Rib Corner Radius | |

| 2CNR | 2 Flutes | Corner Radius End Mills | |

| 4CNR | 4 Flutes | Corner Radius End Mills | |

| 4HCR | 4 Flutes | 45˚Helix Radius Long | |

| 6HCR | 6 Flutes | 45˚Helix Radius Long | |

| 4SCU | 4 Flutes | High Speed Radius Cutter | |

| 6SCU | 6 Flutes | High Speed Radius Cutter | |

| 2LEM | 2 Flutes | Long Length End Mills | |

| 4LEM | 4 Flutes | Long Length End Mills | |

| 3&4SRM | 3&4Flutes | Roughing End Mills | |

| 3&4HRM | 3&4Flutes | 45˚Helix Long Shank End Mills | |

| K GRAPHITE |

2GLM | 2 Flutes | Long Shank End Mills |

| 4GLM | 4 Flutes | Long Shank End Mills | |

| 6GLM | 6 Flutes | 45˚Helix Long Shank End Mills | |

| 2GLB | 2 Flutes | Long Shank Ball End Mills | |

| 2TLB | 2 Flutes | Taper Neck Ball End Mills | |

| 2DBL | 2 Flutes | Diamond Coated Ball End Mills | |

| 4DBL | 4 Flutes | Diamond Coated Ball End Mills | |

| 2DLM | 2 Flutes | Diamond Coated End Mills | |

| 4&6DLM | 4&6 Flutes | Diamond Coated End Mills | |

| 2DLR | 2 Flutes | Diamond Coated Radius | |

| 4DLR | 4 Flutes | Diamond Coated Radius | |

| K SUS |

4HSB | 4 Flutes | 45˚Helix Ball End Mills |

| 3HSM | 3 Flutes | 45˚Helix End Mills | |

| 4NSM | 4 Flutes | Non Symmetry End Mills | |

| 4NSR | 4 Flutes | Non Symmetry Corner Radius | |

| K COPPER |

2HOB | 2 Flutes | 45˚Helix Rib Ball End Mills |

| 2OCR | 2 Flutes | Rib Corner Radius | |

| 3HOR | 3 Flutes | 45˚Helix Rib Radius | |

| K DLC |

2LRB | 2 Flutes | DLC Coated Rib Ball |

| 2LRE | 2 Flutes | DLC Coated Rib End Mills | |

| 3LHE | 3 Flutes | 45˚Helix DLC Coated Rib | |

| 2LCB | 2 Flutes | DLC Coated Ball End Mills | |

| 2LCE | 2 Flutes | DLC Coated End Mills | |

| 2LCR | 2 Flutes | DLC Coated Corner Radius | |

| K ALUMINUM |

3AHM | 3 Flutes | 45˚Helix Rib End Mills |

| 2AHE | 2 Flutes | 45˚Helix End Mills | |

| 3AHE | 3 Flutes | 45˚Helix End Mills | |

| 3AHR | 3 Flutes | 45˚Helix Corner Radius | |

| 3ARM | 3 Flutes | Semi Finishing & Roughing | |

| 3ARR | 3 Flutes | Semi Finishing &Roughing Radius | |

| 3ARH | 3 Flutes | 45˚Helix Roughing End Mills | |

| K TAPER |

3ITB | 3 Flutes | Taper Ball For Impeller |

| 2TBM | 2 Flutes | Taper Ball End Mills | |

| 2TEM | 2 Flutes | Taper End Mills | |

| 4TEM | 4 Flutes | Taper End Mills | |

| 4TRE | 4 Flutes | Rib Taper End Mills | |

| K ABS |

1NEM | 1 Flutes | End Mills |

| 1NRM | 1 Flutes | Reverse Edge End Mill | |

| 2NEM | 2 Flutes | End Mills | |

| 3NEM | 3 Flutes | End Mills | |

| 2NBE | 2 Flutes | Ball End Mills | |

| 3NBE | 3 Flutes | Ball End Mills | |

| 2NLE | 2 Flutes | Micro Long End Mills | |

| 2NLB | 2 Flutes | Micro Long Ball | |

| K GENERAL |

2HGB | 2 Flutes | Ball End Mills for Generality |

| 2HGE | 2 Flutes | End Mills for Generality | |

| 4HGE | 4 Flutes | End Mills for Generality | |

| 2NGR | 2 Flutes | Corner Radius for Generality | |

| 4NGR | 4 Flutes | Corner Radius for Generality |

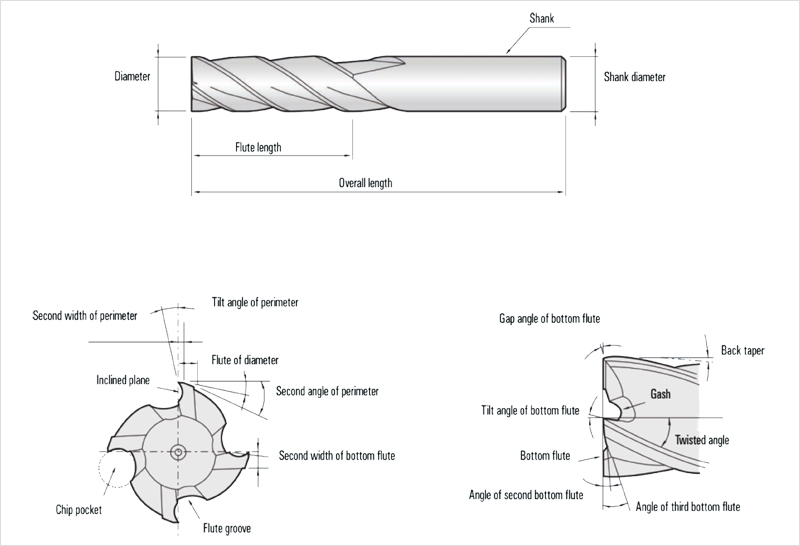

[End mill each Part name]

The shape of the end mill has 3 parts that are cutting part, shank part which supports the milling machine and neck part which connects to the shank part.

• Outside diameter : the maximum external diameter of the cutting edge of End Mill

• Shank diameter : the maximum external diameter of the shank part of End Mill

• Shank length : length of the support in the milling machine

• Length of cut : length of the cutting part of End Mill

• Overall length : whole length of the cutting part, shank part and neck part at the center line of the End Mill

• Number of blades : It refers the number of the cutting blades. There are various types such as 1, 2, 3 or 4 blades but generally 2, 3, 4, 5 and 6 blades are commonly used.

• Shank diameter : the maximum external diameter of the shank part of End Mill

• Shank length : length of the support in the milling machine

• Length of cut : length of the cutting part of End Mill

• Overall length : whole length of the cutting part, shank part and neck part at the center line of the End Mill

• Number of blades : It refers the number of the cutting blades. There are various types such as 1, 2, 3 or 4 blades but generally 2, 3, 4, 5 and 6 blades are commonly used.

[Name of the radial cutting edge]

• Rake angle : It's very important part in the cutting performance of the End Mill. It means the angle between the hollow surface and the assumed center line when seeing the bottom end teeth from straight ahead.

• Radial primary relief : It means the first angle of the radial cutting part that is important in cutting performance as the rake angle.

• Radial secondary relief : It is the next angle from the primary relief that makes the sufficient space between the work material and End Mill during the cutting process.

• Land width : whole width and both radial primary and secondary reliefs.

• Overall length : whole length of the cutting part, shank part and neck part at the center line of the End Mill

• Flute : It's used in the passage that chip can be passed during the cutting process. Also, when this flute gets smaller, it influences the whole cutting process because chip cannot be discharged smoothly.

• Radial primary relief : It means the first angle of the radial cutting part that is important in cutting performance as the rake angle.

• Radial secondary relief : It is the next angle from the primary relief that makes the sufficient space between the work material and End Mill during the cutting process.

• Land width : whole width and both radial primary and secondary reliefs.

• Overall length : whole length of the cutting part, shank part and neck part at the center line of the End Mill

• Flute : It's used in the passage that chip can be passed during the cutting process. Also, when this flute gets smaller, it influences the whole cutting process because chip cannot be discharged smoothly.

[Name of the End Teeth]

• Helix angle : angle of the twisted part along the temporary axis.

• End Teeth : Cutting part that is attached in the bottom of the cylinder End Mill

• Gashing : the passage that the processed chip can be passed during the cutting process.

• End teeth relief angle : tilt angle of the bottom cutting part on the axis.

• Axial primary relief : the tilt angle of the bottom cutting part on the temporary surface.

• Axial secondary relief : the angle that is next to the axial primary relief.

• Concavity(=DISH) : angle of bottom cutting edge toward the center of diameter, which both sides of the bottom cutting part of End Mill passes.

• End Teeth : Cutting part that is attached in the bottom of the cylinder End Mill

• Gashing : the passage that the processed chip can be passed during the cutting process.

• End teeth relief angle : tilt angle of the bottom cutting part on the axis.

• Axial primary relief : the tilt angle of the bottom cutting part on the temporary surface.

• Axial secondary relief : the angle that is next to the axial primary relief.

• Concavity(=DISH) : angle of bottom cutting edge toward the center of diameter, which both sides of the bottom cutting part of End Mill passes.

[Types of the cutting part]

[Classification of the End Teeth type]

[Carbide End Mill]

• The discharge of chips and rigidity of tools by the number(N) of flutes.

The number of flutes is essential part to control the performance of end mills. Generally, if there are few flutes, it is easy to discharge of chips but relatively section areas get smaller so that it makes the rigidity of tools fall down and enable tools to sway on cutting. On the other hand, if there are many flutes, the section areas get larger and the rigidity gets higher but the chip capacity goes down owing to lessened the chip pocket and it is easily blocked up by chips.

• The rigidity of tools by the length(L) of the flute

The shorter length of tools, the higher the rigidity and performance of cutting. The length of the flute become twice, the rigidity of end mills falls to 1/8. Because end mills are the tools to move horizontal, it is important for the rigidity of tools to be in inverse proportion to the length of tools. Using a longer flute that need be is not good. You can choose suitable flutes for your cutting conditions now that COGO TOOLS, we have a variety of items.

The number of flutes is essential part to control the performance of end mills. Generally, if there are few flutes, it is easy to discharge of chips but relatively section areas get smaller so that it makes the rigidity of tools fall down and enable tools to sway on cutting. On the other hand, if there are many flutes, the section areas get larger and the rigidity gets higher but the chip capacity goes down owing to lessened the chip pocket and it is easily blocked up by chips.

• The rigidity of tools by the length(L) of the flute

The shorter length of tools, the higher the rigidity and performance of cutting. The length of the flute become twice, the rigidity of end mills falls to 1/8. Because end mills are the tools to move horizontal, it is important for the rigidity of tools to be in inverse proportion to the length of tools. Using a longer flute that need be is not good. You can choose suitable flutes for your cutting conditions now that COGO TOOLS, we have a variety of items.

Other Products

R&D CERTIFICATE

-

- R&D Certificate

- koita

- 2018.02.19

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : Chris You

SHIPPING

Shipping from :

Republic of Korea

- 19 Gasan digital 1-ro (08594)

- Air Cargo : Please contact us for inquiry on carriers

- Sea Freight : Please contact us for carriers inquiry

- Land Transportation

- Sea Freight : impossible

- Please contact your administrator for detailed information.

- Name : Eun Kyung,Cha

- Tel : 82-70-7162-7910

COGO TOOL Co., Ltd.

The person in charge

Jae Gun LeeAddress

19 Gasan digital 1-ro, Geumcheon-gu, Seoul (08594)

코고툴

COGO TOOL Co., Ltd.

Introduction

Our company, established in 2008, is a Korean carbide endmill producer.

Our company has endmills and drills for cutting various materials such as graphite rpocessing, cooper processing, aluminum processing, general steel, hard steel and so on.

we always appreciate our customers.

As filling up new items like endmills of CBN/for SUS/for cutting copper in order to meet customer demands, We line up about 8,888 items.

It is every product of COGOTOOL that all of our staff pay attention to production and quality control without any careless.

Continued from now on, COGOTOOL make our best to supply excellent products low-priced by advanced technology and efficient process improvement.

Currently, it is exported to more than 30 countries including Italy, India, and Turkey.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Carbide End Mill, Insert,High Performance Carbide End Mills

-

- Established :

- 2008-06-05

-

- Total Annual Revenue :

- 2~3 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 2~3 billion (KRW)

-

- Total export revenue (previous year in USD)

- 2

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- COGO TOOL Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★