Prototype For Large Automobile Plastic Parts

-

Payment

T/T

-

MOQ

100 Unit

-

Supply Ability

10,000 Unit per One-Time

-

Supply Details

Customization Sample Order

Depend on quantity / If you want bulk purchase, please contact me.

-

Country of sale

Asia, Europe, World Wide, Africa, Americas

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

DUSON INTERNATIONAL

-

origin

Republic of Korea

-

Size(Capacity)

Inquiry

-

Weight

Inquiry

-

Style

Inquiry

-

Material

Automobile Plastic

-

Function

Automobile parts :Prototype For Large Plastic Parts,Sheet Metal Press Mold

PRODUCT DESCRIPTION

Prototype For Large Plastic Parts

• BUMPER, R/GRILLE, CVR-COWL TOP PNL-INSTRUMENT, TRUNK-LID, LUGG SIDE TRIM, FLOOR-CONSOLE, DOOR TRIM

[Product Description]

• Plastic injection parts for Automobile interior and exterior

• The mechanical know-how of internal and external plastic injection molding products provides high-quality products.

• ZAS(Zinc Alloy Steel) Use ZAS instead of steel as mold material

• The mechanical know-how of internal and external plastic injection molding products provides high-quality products.

• ZAS(Zinc Alloy Steel) Use ZAS instead of steel as mold material

ZAS has the following features:

• Low melting temperature and fluidity make casting easy

• Easy to process

• Easy design change with excellent weldability

• Casting with pre-manufactured cooling line(less mechanical work)

• Cost savings with eco-friendly recycling materials

ZAS Material Composition

• AL: 3.9~4.3%, CU:2.85~3.35%, FE:0.075% or less, Mg:0.03~0.06% SN:0.002% or less, Pb: 0.003 or less Cd:0.001 or less, Zn: 93%

• We use a one-stop process that is effective in developing a prototype car :ZAS casting and mold production, from manufacturing to injection molding

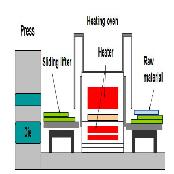

RIM(Reaction Injection molding)

• Use two types of materials with low molecular weight, low viscosity, and high reactivity

• This material is injected into the mold and reacts immediately to form a part of the polymer resin.

• RIM function compared to injection molding formed at relatively low temperatures(Resin temperature:20~50, Mold temperature 40~80)

• Internal pressure of mold(3~5kg/cm2(IM:250~300)

• Large, complex parts with low viscosity and good flow can be easily molded.

• less scratches in BOSS and RIM.

• Thin material injected into the mold makes it easier to make complex parts

• Low melting temperature and fluidity make casting easy

• Easy to process

• Easy design change with excellent weldability

• Casting with pre-manufactured cooling line(less mechanical work)

• Cost savings with eco-friendly recycling materials

ZAS Material Composition

• AL: 3.9~4.3%, CU:2.85~3.35%, FE:0.075% or less, Mg:0.03~0.06% SN:0.002% or less, Pb: 0.003 or less Cd:0.001 or less, Zn: 93%

• We use a one-stop process that is effective in developing a prototype car :ZAS casting and mold production, from manufacturing to injection molding

RIM(Reaction Injection molding)

• Use two types of materials with low molecular weight, low viscosity, and high reactivity

• This material is injected into the mold and reacts immediately to form a part of the polymer resin.

• RIM function compared to injection molding formed at relatively low temperatures(Resin temperature:20~50, Mold temperature 40~80)

• Internal pressure of mold(3~5kg/cm2(IM:250~300)

• Large, complex parts with low viscosity and good flow can be easily molded.

• less scratches in BOSS and RIM.

• Thin material injected into the mold makes it easier to make complex parts

[Major customer(%)]

• TOYOTA,HONDA,SUZUKI, HYUNDAI, KIA

[Major products(%)]

• Automobile parts :Prototype For Large Plastic Parts,Sheet Metal Press Mold

• Production: Progressive: Transfer, Tandem

• Production: Progressive: Transfer, Tandem

Other Products

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Choi jin Seok

SHIPPING

Shipping from :

Republic of Korea

- 44 Charyong-ro 48beon-gil Uichang-gu, Changwon-si, Gyeongsangnam-do (51391)

Duson International co., Ltd.

The person in charge

Jin Seok ChoiAddress

44 Charyong-ro 48beon-gil Uichang-gu, Changwon-si, Gyeongsangnam-do (51391)

두손인터내셔널

Duson International co., Ltd.

Introduction

Starting with the press mold of the Japanese automotive plate press component makers, plastic prototype component makers, Interior decoration component makers, hypoid gear, bevel gear in charge of manufacturing inspection tools, transport devices, etc. and preparing for production in world wide car makers

Manufacturing environment that has a competitive edge over Japanese peers.

We are manufactureing large prototype plastic parts(injection,CFRP, GFRP), mold&steel press dies, ething products, and hypoid gear&bevel gear for automobile parts.

Japan Japanese companies are increasingly favoring Korean products.

-

- Business Type :

- Manufacturer

-

- Main Product :

- automotive parts, press mold, hypoid gear, bevel gear

-

- Established :

- 2010-07-01

-

- Total Annual Revenue :

- 1~2 billion (KRW)

-

- Total Employees :

- 5~10 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 1~2 billion (KRW)

-

- Total export revenue (previous year in USD)

- 890

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- Duson International co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★