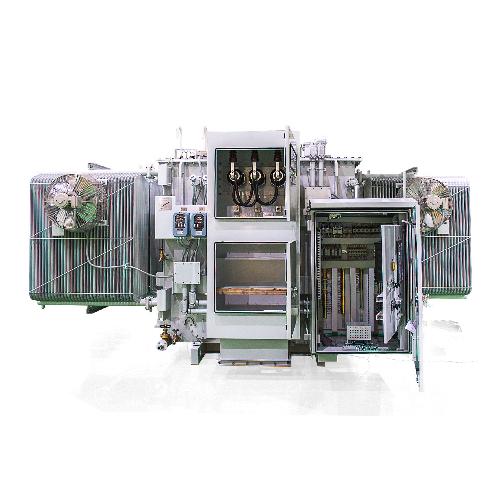

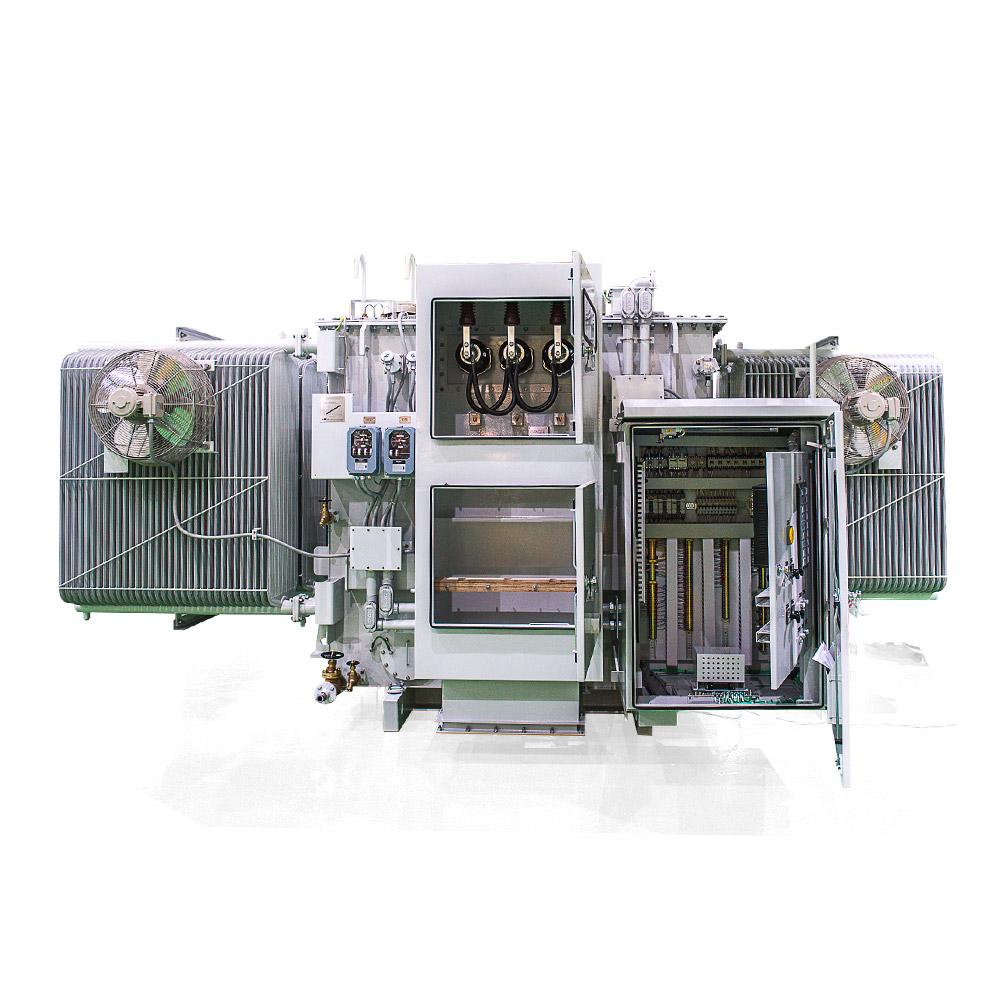

El Power Tech Transformer

-

Payment

L/C(usance) , T/T

-

MOQ

Negotiable

-

Supply Details

We should always follow the buyer’s payment terms.

-

Country of sale

Asia, Americas, Europe, Middle East, World Wide

-

PRICE

-

FOB

USD 0.00 ~ 0.00

(1 ea)

-

ITEM SPECIFICS

-

Brand

Model TransformerEl Power Tech

-

origin

Republic of Korea

-

Size(Capacity)

10kVA~50,000kVA

-

Function

Transfers electrical energy

-

Gender

For industry use

-

age-appropriate

For industry use

-

Features

Transfers electrical energy

-

Expiry Date

up to 3 months

PRODUCT DESCRIPTION

[Technology]

1. Electrical Design

It is our specialty to creatively design for a variety of requests from various clients. Regardless of the type of winding, we design without any limitation of insulation class nor temperature rise. This is why any unique specification is welcomed to be custom-made for any circumstances including voltage, current, configuration and frequency. Over a decade’s hard work and dedication give us Know-how in terms of design, manufacturing and QA. This is why we can supply only state-of-the-art products through systemic verification procedure as well as design analysis program as below:

■ Inrush Current Analysis

■ Thermal and Mechanical strength Analysis (caused by short-circuit)

■ Electric Field Distribution Analysis

■ Insulation Level

■ K-factor Analysis

■ Equipment Reliability Analysi

2. Magnetic Core

Cold Rolled Grain-oriented steel (CRGO) which has high magnetic permeability is the one used as a Magnetic Core, and our own know-how in designing and cutting is applied to dramatically reduce no-load current and no-load loss. Our precise producing and manufacturing process can minimize vibration and noise, also make it have enough solidity and strength to support winding.

3. High Voltage Winding

Electrical Coil Winding - a quality conductor covered with suitable electrical insulating materials is designed and manufactured to achieve high-class insulation as well as smooth cooling. Every outgoing line is supported by insulating materials, and coil’s connecting part is fully contacted by welding or compression. Insulating class and mechanical strength are taken into consideration so coil winding can withstand electrical surge and abnormal voltage thoroughly. Furthermore, outer parts are reinforced in case of electromagnetic mechanical power occurrence while short-circuit. Plus, NOMEX is used for the H class insulation of Dry Type.

4. Quality Assurance System

ISO 9001 / ISO 14001 standards are adopted to keep supplying both reliable and eco-friendly products. Also, rigorous tests are conducted in accordance with global standards such as IEC, UL, CE, JEC, KS, etc.

[Product Feature]

A transformer is a passive electrical device that transfers electrical energy from one electrical circuit to another, or multiple circuits. A varying current in any one coil of the transformer produces a varying magnetic flux in the transformer's core, which induces a varying electromotive force across any other coils wound around the same core. Electrical energy can be transferred between separate coils without a metallic (conductive) connection between the two circuits

R&D CERTIFICATE

-

- KS Certificate

- Korean standards association

- 2018.07.09

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(usance)

- Telegraphic Transfer : T/T

- Name : SEONG KYU CHOI

SHIPPING

Shipping from :

Republic of Korea

- 144 Cheongwonsandan-ro Mado-myeon, Hwaseong-si, Gyeonggi-do (18541)

ELPOWERTECH

The person in charge

CHOI SEONG KYUAddress

144 Cheongwonsandan-ro Mado-myeon, Hwaseong-si, Gyeonggi-do (18541)

Introduction

EL POWER TECH is the leader in power and integrated systems, especially

renowned in Asia as well as in Korea based on customers’ trust.

Since its establishment in 2000, with the mission to be the leader in delievering

quality products and services that meet the needs and requirements of our

customers and contribute to their success.

We have numerous intellectual property rights such as UL, CE, KS certificatios

and patents, utility models.

In particular, Phase Shift Dry Type Transformer and Reactor for Medium Voltage

Drives have been supplied YASKAWA ELECTRIC CORPORATION in Japan for the

last several years.

Global Company, Active ELPOWERTECH” promises to provide quality produts as

always.

-

- Business Type :

- Manufacturer

-

- Main Product :

-

- Established :

- 2000-07-20

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- KS Certificate

- Korean standards association

- 2018.07.09

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 1,000,000

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- ELPOWERTECH Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★