Turbine Valve Actuator Tester (TVAT)

-

Payment

L/C(usance) , T/T , WK

-

MOQ

1 ea

-

Supply Ability

10 ea per Month

-

Supply Details

Customization

-

Country of sale

World Wide, Americas, Middle East, Europe, Asia

-

PRICE

-

FOB

USD 300,000.00

(1 ea)

-

CIP

USD 300,000.00

(1 ea)

-

CIF

USD 300,000.00

(1 ea)

-

ITEM SPECIFICS

-

Brand

Model MR-TVAT-10-180Future Automation Co.,Ltd

-

origin

Republic of Korea

-

Size(Capacity)

1200 x 1100 x 1750(H)

-

Package Includes

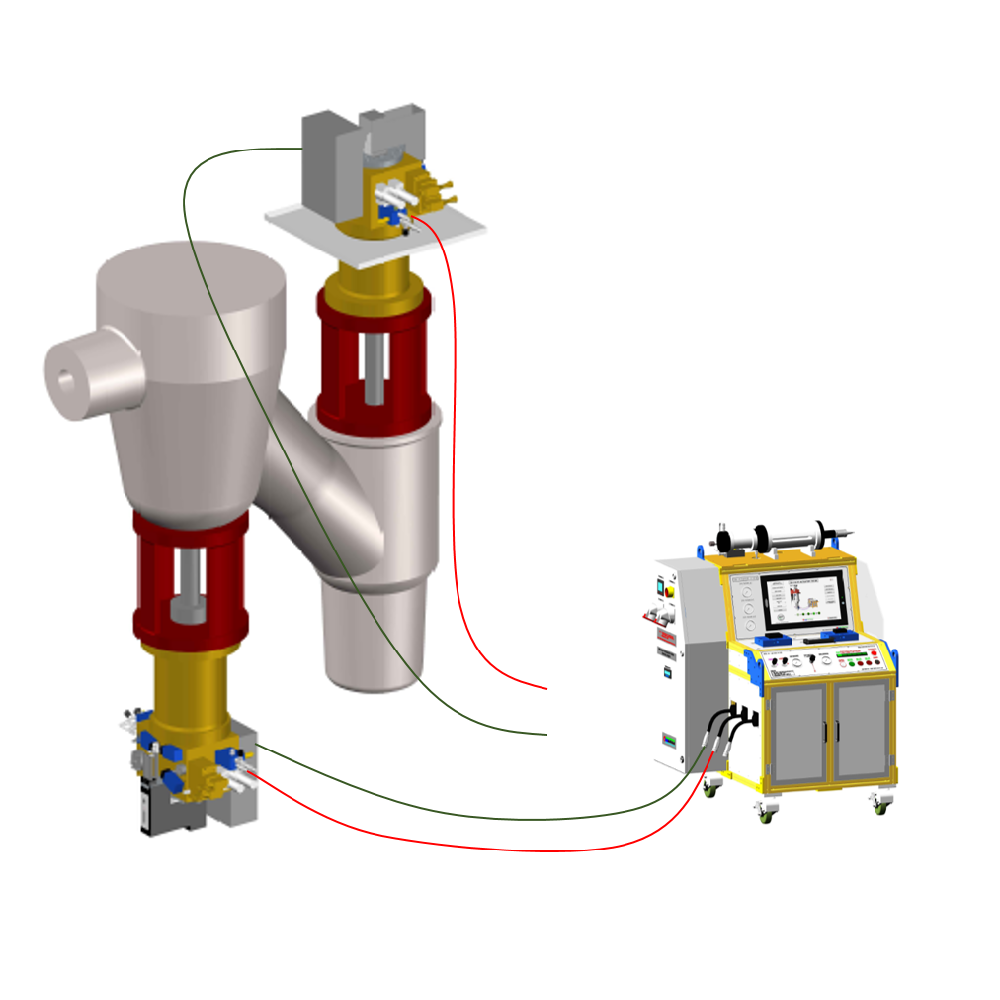

Monitor, Hydraulic Power Unit, Control Panel, Flowmeter

-

Color

Silver, yellow

-

Weight

500kg

-

Features

Actuator Replacement Cycle Life Prediction Diagnosis

-

age-appropriate

More than 10 years

-

Function

Diagnose the performance of hydraulic actuator of turbine valve

-

Material

Aluminum, SUS304

-

Style

Field Removable

PRODUCT DESCRIPTION

Turbine Valve Actuator Tester (TVAT) for Power Plants

- Ensure durability and reliability through preliminary overall inspection without separating the actuator from the system.

- Reduced maintenance costs by 1/40man/hour.

- Establishment of power generation maintenance technology through Demonstration of the integrity of the power plant before installing the system

★ ★ Turbine Valve Hydraulic Actuator Prediction Diagnostic Solution!!!

▶ Reduced maintenance costs by 1/40Man/hour.

▶ Diagnosis & contaminated oil flushing at the same time

It was impossible to diagnose the performance of hydraulic actuator of turbine valve, which is a main core device installed for controlling the amount of evaporator supplied to turbines of nuclear power generation and thermal power generation, without separation from the system.

But the present Performance Prediction Diagnostic Tester(TVAT) for Turbine Valve Actuators is improved to be possible this diagnosis. This movable local tester makes the improvement of International creditworthiness to be possible through actual preventive maintenance, integrity evaluation, improvement of power quality, stable power production and reliability securement of maintenance for power generation by pre-performance test about this hydraulic actuator.

Future Automation Co., Ltd. was founded in May 1998 as a company with the mission of "Challenging mind and customer satisfaction". Through the engineering, design, manufacture and installation of industrial sectors’ pneumatic, hydraulic , and vacuum system, we are in charge of the efficiency, environmental management, productivity, and product quality of each industry.

Especially, it is important to check the performance of turbine valve hydraulic actuators, which is a core device installed to control the amount of steam supplied to the turbines of nuclear power plants and thermal power plants. "Performance Prediction Diagnostic Tester(TVAT) for Turbine Valve Hydraulic Actuators" evaluates performance through diagnosis of malfunctions in advance and increased reliability of the power plant’s maintenance and diagnosis technology. It was distributed to power plants and favorably received to power generation companies for its successful performance on the power plant site demonstration test.

The "Performance Prediction Diagnostic Tester(TVAT) for Turbine Valve Hydraulic Actuators“, the world’s first developed tester in the area of futuristic automation, is a new product that has been verified of its performance and successfully applied on the field of power plants. We have gained the new product (NEP) certification, and we are concentrating on expanding distribution to domestic power generation companies . We are also mainly working on strengthening our marketing competence to secure overseas production and sales based in China, Europe, Russia and Southeast Asia, UAE, Turkey, USA and promoting new market openings.

▶ The TVAT will contribute to the safety of the operation and the improvement of the operation rate of the Nuclear and thermal power plants.

▶ "TVAT" has been favorably received by Wolsung nuclear power plant(KHNP) and thermal power plant in Korea with successful the field test.

- Busan power plant

- Yeongdong power plant

- Hadong power plant1

- Youngheung power plant

- Donghae power plant

- Taean power plant

- Wolseong Nuclear power plant

- Incheon power plant

- Shin Bo-ryeong power plant

- Gunsan power plant

- Ulsan power plant

- Samcheonpo power

- Hadong power plant 2

- Taean power plant 2

- Dangjin power plant

- Boryeong power plant

◈ Performance Diagnosis Items

① Performance diagnostic test for turbine valve hydraulic actuator

② Dump housing seat & dumping speed test

③ Contaminated Hydraulic oil flushing

④ Automatic determination of maintenance and replacement cycle predicting diagnosis test for malfunction

⑤ Verification test of performance of after maintenance

⑥ Self actuating trial run before configuration synchronization

⑦ Real time failure prediction monitoring system(Option)

▶ In particular, pre-inspection and commissioning test for actuators before system feeding in new power plants

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(usance)

- WK

- Telegraphic Transfer : T/T

- Name : uk kyoung Jeun

SHIPPING

Shipping from :

Republic of Korea

- 93, Cheyukgongwon-ro 6beon-gil, Gangseo-gu, Busan, Korea (46703)

- Sea Freight : Please contact us for carriers inquiry

- Sea Freight : possible

- Please contact your administrator for detailed information.

- Name : uk kyoung,Jeun

- Tel : 82-051-316-5650

FUTURE AUTOMATION CORP.

The person in charge

KYE CHEON YOUNAddress

93 Cheyukgongwon-ro 6beon-gil, Gangseo-gu, Busan (46703)

QR CODE

FUTURE AUTOMATION CORP.

Introduction

Future Automation Co., Ltd. was founded in May 1998 as a company with the mission of "Challenging mind and customer satisfaction". Through the engineering, design, manufacture and installation of industrial sectors’ pneumatic, hydraulic , and vacuum system, we are in charge of the efficiency, environmental management, productivity, and product quality of each industry.

Especially, it is important to check the performance of turbine valve hydraulic actuators, which is a core device installed to control the amount of steam supplied to the turbines of nuclear power plants and thermal power plants. "Performance Prediction Diagnostic Tester for Turbine Valve Hydraulic Actuators (TVAT)" evaluates performance through diagnosis of malfunctions in advance and increased reliability of the power plant’s maintenance and diagnosis technology. It was distributed to power plants and favorably received to power generation companies for its successful performance on the power plant site demonstration test.

The "Performance Prediction Diagnostic Tester for Turbine Valve Hydraulic Actuators (TVAT)", the world’s first developed tester in the area of futuristic automation, is a new product that has been verified of its performance and successfully applied on the field of power plants. We have gained the new product (NEP) certification, and we are concentrating on expanding distribution to domestic power generation companies . We are also mainly working on strengthening our marketing competence to secure overseas production and sales based in China, Europe, Russia and Southeast Asia, and promoting new market openings.

Thank you

President Engineer K.C YOUN

代表 尹啓天 拜上

-

- Business Type :

- Manufacturer

-

- Main Product :

- Turbine Valve Hyd Actuator Tester

-

- Established :

- 1998-05-11

-

- Total Annual Revenue :

- 6 million to 10 billion (KRW)

-

- Total Employees :

- 5~10 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 6 million to 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 2

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- FUTURE AUTOMATION CORP. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

SUPPLIER BEST

- No Items