ITEM SPECIFICS

-

Brand

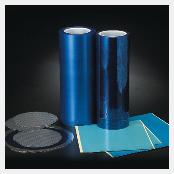

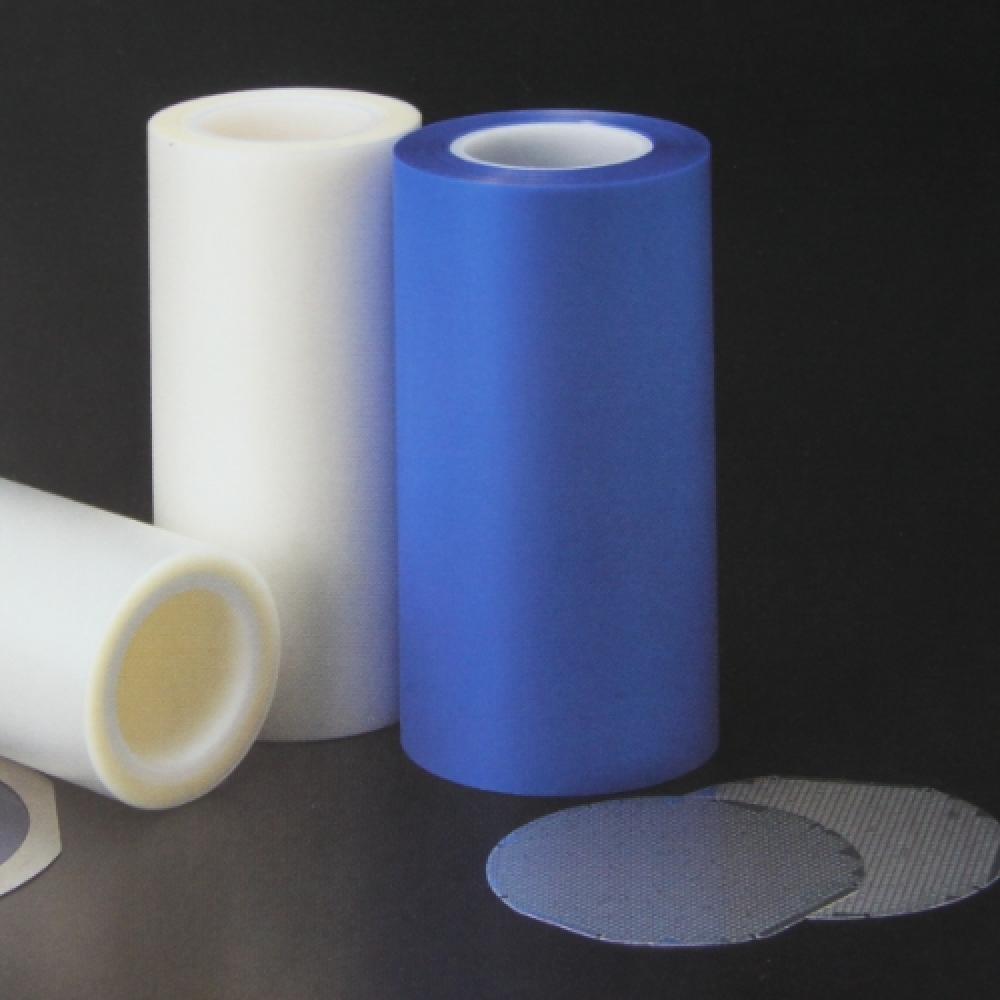

Model AT-380 SERIESNON-UV DICING TAPE

-

origin

Republic of Korea

-

Size(Capacity)

1200mm x 100m

-

Material

POLYETHYLENE FILM

-

Color

TRANSPARENT, BLUE, WHITE

-

Weight

14 KG/ROLL

-

Dimensions

240 sqm

-

Function

TO PROTECT SURFACE OF SUBSTRATE

-

Expiry Date

6 month sinc production date

-

Features

Good quality with competitive price

PRODUCT DESCRIPTION

1. Introduction.

The surface protective tape offers stable surface protective for cutting, punching, in-process transport and shipment for such substrates as PMMA (acrylic) plates, Polycarbonate plates and LCD polarizing films. Wide variety of surface protective materials to meet customers' needs. To select the surface protective material most suitable for the application and envirnment in which it is going to be used.

2. Features.

1) Unlike traditional adhesive coated type, the adhesive does not contaminate the substrate due to co-extrusion method of thermoplastic materials.

2) Transparency shows surface of the substrate without removing the tape.

3) Low adhesion, suitable for smooth surface.

4) Minimal change in adhesive strength following applciation ensures easy peeling.

5) Products can adjust various surface roughness and process levels.

6) Offers excellent initial adhesion and easy application, Film can be easily peeled off after attaching on surface of substrate.

7) Extremely small changes in adhesive strength after lamination, ensuring easy peeling.

8) Minimally affected by the surface condition of the substrate, making it applicable for a wide range of substrates.

9) Light unwinding force and easy lamination.

10) Suitable for various objectives and locations.

11) Excellent leaving minimal adhesive residue.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : KI CHUL NAM

SHIPPING

Shipping from :

Republic of Korea

- 305 ROAD DAEGOT-BUKRO, DAEGOT-MYUN, KIMPO-CITY, KYUNGGI-DO (10028)

ADTECH CO.,LTD

The person in charge

YOUNG JOO YOONAddress

305 ROAD DAEGOT-BUKRO, DAEGOT-MYUN, KIMPO-CITY, KYUNGGI-DO (10028)

Introduction

Adtech Co.,Ltd. Is a professional company specialzing in surface protecting adhesvive tape and since the establishment in 1996, the company has been striving for putting customer satisfaction at home and abroad as its priority. Adtech Co.,Ltd will do its utmost to join the line with the world's top-ranking companies creating the best value through continuous customer satisfaction with endless challenge and creation, innovation and responsibility in mind. Please take a close attention to Adtech Co.,Ltd. as it will always be with customers.

-

- Business Type :

- Manufacturer

-

- Main Product :

- SURFACE PROTECTION FILM

-

- Established :

- 1996-12-05

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 11~50 people

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 3

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- ADTECH CO.,LTD Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★