ITEM SPECIFICS

-

Brand

Unbranded

-

origin

Republic of Korea

-

Size(Capacity)

12" x 18" x 3"

PRODUCT DESCRIPTION

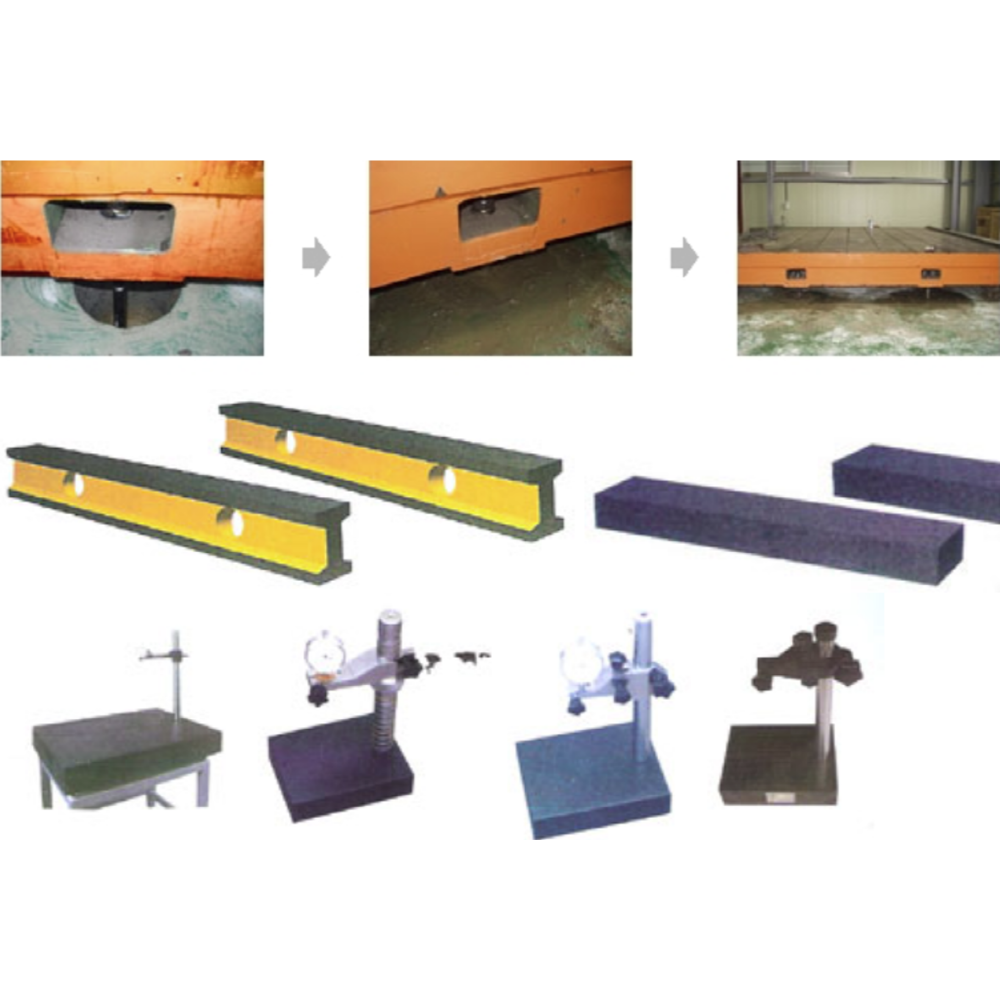

Granite surface Description

The surface plate is a solid flat plate used as the main horizontal reference plane for inspection,

The surface plate is a solid flat plate used as the main horizontal reference plane for inspection,

marking out (layout) and tool setting.

Since the surface plate is often used as the baseline for all measurements on the workpiece,

Since the surface plate is often used as the baseline for all measurements on the workpiece,

one major surface is extremely flat with an accuracy of 0.00001 in or 250 nm for AA or AAA grades.

The surface plate is the most common tool in the manufacturing industry and is often permanently attached to

The surface plate is the most common tool in the manufacturing industry and is often permanently attached to

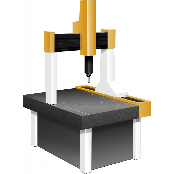

a robotic test device such as a coordinate system.

Plates are typically square or rectangular.

Plates are typically square or rectangular.

One current UK standard includes specifications for plates from 160 mm × 100 mm to 2500 mm × 1600 mm.

Granite surface material

Damage to the granite surface plate generally produces chips, but does not affect the accuracy of the entire plane.

Damage to the granite surface plate generally produces chips, but does not affect the accuracy of the entire plane.

Although crumbling, other flat surfaces can still come into contact with the undamaged portion of the crushed surface plate,

but damage to the cast plate often raises the surrounding material on the work surface so that

the test object is no longer placed parallel to the surface plate I will.

Granite is also inherently stable, non-magnetic and has excellent vibration damping properties and does not rust.

Granite is also inherently stable, non-magnetic and has excellent vibration damping properties and does not rust.

Available accessories

Plates are used with accessories such as square, straight, gauge blocks, sine bars, sine plates, dial indicators,

Plates are used with accessories such as square, straight, gauge blocks, sine bars, sine plates, dial indicators,

parallel plates, angle plates and height gauges.

Others

Good abrasion resistance (6~10 times than iron surface plate)

No transformation, long life

Less impact by temperature

No corrosion and projection

Not magnetic substance -High surface finish

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : AN, SEONG-GI AN

SHIPPING

Shipping from :

Republic of Korea

- 16,Soto 2-gil,Sangbuk-myeon, Yangsan-si, Gyeongsangnam-do,Korea (50566)

TECHAN CO., LTD.

The person in charge

SEONG-GI ANAddress

16,Soto 2-gil,Sangbuk-myeon, Yangsan-si, Gyeongsangnam-do,Korea (50566)

Introduction

Techan ™ , established to be a part of industrial development of Korea, is making efforts to be the company

that develops together with customers through customer-centered management as well as endless technical

and managerial innovations to cope with the change of industrial environment aggressively in the inside and outside of the country.

Techan ™ has secured top class technical power by endless research and development for IT

and precision measuring instrument industries. Based on the technology, the company is growing as a company

to lead the change of IT and precision measuring instrument industries, reinforcing the role of an intermediary

between vendor and customer to provide solutions to meet customer’s business intention.

All the employees and executives of Techan ™ will advance the new future by customer-centered management

in which the realization of customer’s profit creation is considered as the highest value,

with customer-centered thinking from the viewpoint of customer.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Three-dimensional Measuring Instrument

-

- Established :

- 2000-01-01

-

- Total Annual Revenue :

- Less than 100 million (KRW)

-

- Total Employees :

- Less than 5

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- Less than 100 million (KRW)

-

- Total export revenue (previous year in USD)

- 1

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- TECHAN CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★