ITEM SPECIFICS

-

Brand

Unbranded

-

origin

Republic of Korea

-

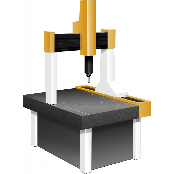

Size(Capacity)

180mm*1935mm*405mm(145kg)

PRODUCT DESCRIPTION

1) Realization of light weight by the design with special aluminum material

2) Maintenance of finish stability by bearing support structure

3) Soft conveying of material due to coating the surface

4) Multipurpose layout machine by simple operation and feasible use

2) Maintenance of finish stability by bearing support structure

3) Soft conveying of material due to coating the surface

4) Multipurpose layout machine by simple operation and feasible use

Name: LAYOUT The name M / C is called 2D measuring machine or marking machine. Now it is also called 3D measuring machine LAYOUT M / C by measuring and inspecting.

* summary :

LAYOUT M / C was introduced in Korea since the beginning of 85 years, mainly Japanese products such as TOKYO BOEKI and FUGIOKA were imported, and then several German and Italian products were introduced in Korea.

Currently, there are about 1000 in Korea.

LAYOUT M / C was introduced in Korea since the beginning of 85 years, mainly Japanese products such as TOKYO BOEKI and FUGIOKA were imported, and then several German and Italian products were introduced in Korea.

Currently, there are about 1000 in Korea.

It is mainly used for marking and measurement by automobile manufacturers and related companies.

In the past, products were inspected with white gauge, noggin, and other measuring tools. However, since the industry was highly developed, it required high precision of the products, which made it impossible to equip the inspection equipment. Large companies are now introducing the automation type CNC SYSYEM.

In the past, products were inspected with white gauge, noggin, and other measuring tools. However, since the industry was highly developed, it required high precision of the products, which made it impossible to equip the inspection equipment. Large companies are now introducing the automation type CNC SYSYEM.

* Application:

It is used in products that require inspection and measurement in all industries, but it is mainly used in small, large-sized water products and jigs with complex shapes.

: The department includes automobile design room, model room, start room, mold part, body inspection part, tool part, QC

QA, casting parts, forging parts, machining parts, etc.

It is used in products that require inspection and measurement in all industries, but it is mainly used in small, large-sized water products and jigs with complex shapes.

: The department includes automobile design room, model room, start room, mold part, body inspection part, tool part, QC

QA, casting parts, forging parts, machining parts, etc.

* Model: 12E, 16E, 20E, 25E etc.

* Related items: DIGITAL SYSYEM, Plate, Measurement related PROGRAM, PROBE SYSYEM, etc.

A. Types of DIGITAL SYSYEM

- Simple COUNTER

- SENSOR use COUNTER

- Operation function SYSYEM

- Simple COUNTER

- SENSOR use COUNTER

- Operation function SYSYEM

B. Plate

- Precision machine is an auxiliary equipment that allows the machine to sit on it and places the product on it to perform measurement work, and it is also widely used as a work die.

It is mainly used as a casting, and the processing is used by processing on a Frena milling machine.

- LAYOUT The M / C was imported at the time of introduction, but now it is domestic and the processing technology is developed and it is supplied as national product.

- Various kinds: 3000X2000, 4000X2500, 6000X4000mm and so on.

(Can be made as USER requirement)

- Precision machine is an auxiliary equipment that allows the machine to sit on it and places the product on it to perform measurement work, and it is also widely used as a work die.

It is mainly used as a casting, and the processing is used by processing on a Frena milling machine.

- LAYOUT The M / C was imported at the time of introduction, but now it is domestic and the processing technology is developed and it is supplied as national product.

- Various kinds: 3000X2000, 4000X2500, 6000X4000mm and so on.

(Can be made as USER requirement)

C. Measurement related program

- It is a SYSYEM that compares the measured data by connecting DIGITAL SYSYEM and COMPUTER.

- First, CAD and CATIA design work is done. When the product is produced, the product is compared with measurement data.

- So far, I have made a sheet by hand, but introducing PROGRAM will help me to save time, work efficiency and efficiency.

- It is a SYSYEM that compares the measured data by connecting DIGITAL SYSYEM and COMPUTER.

- First, CAD and CATIA design work is done. When the product is produced, the product is compared with measurement data.

- So far, I have made a sheet by hand, but introducing PROGRAM will help me to save time, work efficiency and efficiency.

D.PROBE SYSYEM

- The name is called TOUCH SENSOR. It is mainly used TP-2 (RENISHAW) and it is auxiliary part used for product measurement and inspection.

- Until now, we have been using marking needle, indegater, etc, but we are going to use sensor to improve the quality of our products.

- The name is called TOUCH SENSOR. It is mainly used TP-2 (RENISHAW) and it is auxiliary part used for product measurement and inspection.

- Until now, we have been using marking needle, indegater, etc, but we are going to use sensor to improve the quality of our products.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Letter of Credit : L/C(sight)

- Name : AN, SEONG-GI AN

SHIPPING

Shipping from :

Republic of Korea

- 16,Soto 2-gil,Sangbuk-myeon, Yangsan-si, Gyeongsangnam-do,Korea (50566)

TECHAN CO., LTD.

The person in charge

SEONG-GI ANAddress

16,Soto 2-gil,Sangbuk-myeon, Yangsan-si, Gyeongsangnam-do,Korea (50566)

Introduction

Techan ™ , established to be a part of industrial development of Korea, is making efforts to be the company

that develops together with customers through customer-centered management as well as endless technical

and managerial innovations to cope with the change of industrial environment aggressively in the inside and outside of the country.

Techan ™ has secured top class technical power by endless research and development for IT

and precision measuring instrument industries. Based on the technology, the company is growing as a company

to lead the change of IT and precision measuring instrument industries, reinforcing the role of an intermediary

between vendor and customer to provide solutions to meet customer’s business intention.

All the employees and executives of Techan ™ will advance the new future by customer-centered management

in which the realization of customer’s profit creation is considered as the highest value,

with customer-centered thinking from the viewpoint of customer.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Three-dimensional Measuring Instrument

-

- Established :

- 2000-01-01

-

- Total Annual Revenue :

- Less than 100 million (KRW)

-

- Total Employees :

- Less than 5

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- Less than 100 million (KRW)

-

- Total export revenue (previous year in USD)

- 1

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- TECHAN CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★