ITEM SPECIFICS

-

Brand

Model I.F.C - 4675Unbranded

-

origin

Republic of Korea

-

Size(Capacity)

W 50 (cm)*D 50(cm)*H80(cm)

PRODUCT DESCRIPTION

[Product Description]

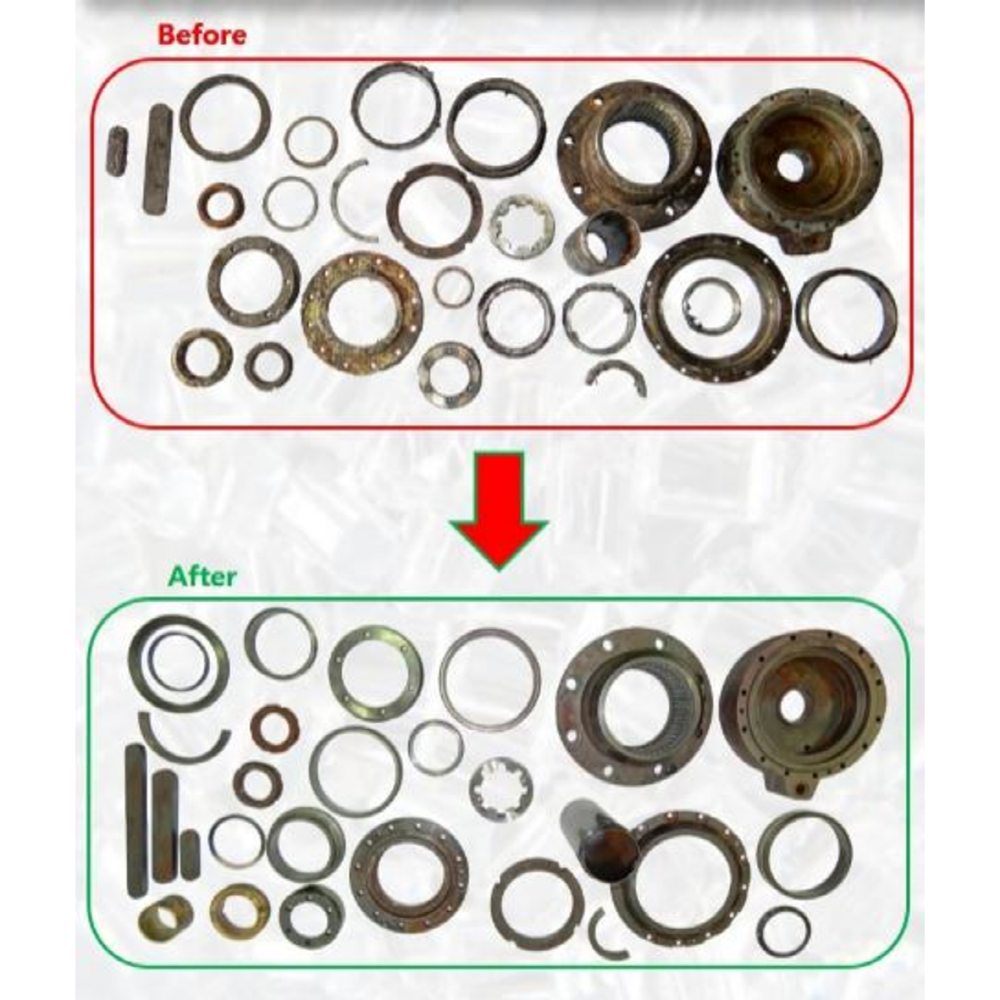

Since the advent of plastic, it has been difficult to remove polymeric residues, powder coatings, oil contaminations and other organic materials from metal parts and extruder hardware. Existing cleaning methods in industry need a lot of money and labor force, and bring about material loss and environmental pollution. Industrial Fluidized Bed Cleaning System is the primary option to solve the problems. The system will provide significant benefits for customers.

[Product Features]

-Safety : No reaction with water and any chemical substances.

No explosion, using an indirect heating system.

-No Material Loss : Possible to remove residues without loss.

-No Abrasion : No physical impact on products.

-No Corrosion : No use of toxic chemicals.

-No Cost : Possible to recycle Thermal Medium.

-Fast : Only 30~60 minutes to finish one cleaning process.

-Easy to Operate : Easy temperature control. Easy operating system.

-No Wide Space : Narrow space is enough to operate the system.

Since the advent of plastic, it has been difficult to remove polymeric residues, powder coatings, oil contaminations and other organic materials from metal parts and extruder hardware. Existing cleaning methods in industry need a lot of money and labor force, and bring about material loss and environmental pollution. Industrial Fluidized Bed Cleaning System is the primary option to solve the problems. The system will provide significant benefits for customers.

[Product Features]

-Safety : No reaction with water and any chemical substances.

No explosion, using an indirect heating system.

-No Material Loss : Possible to remove residues without loss.

-No Abrasion : No physical impact on products.

-No Corrosion : No use of toxic chemicals.

-No Cost : Possible to recycle Thermal Medium.

-Fast : Only 30~60 minutes to finish one cleaning process.

-Easy to Operate : Easy temperature control. Easy operating system.

-No Wide Space : Narrow space is enough to operate the system.

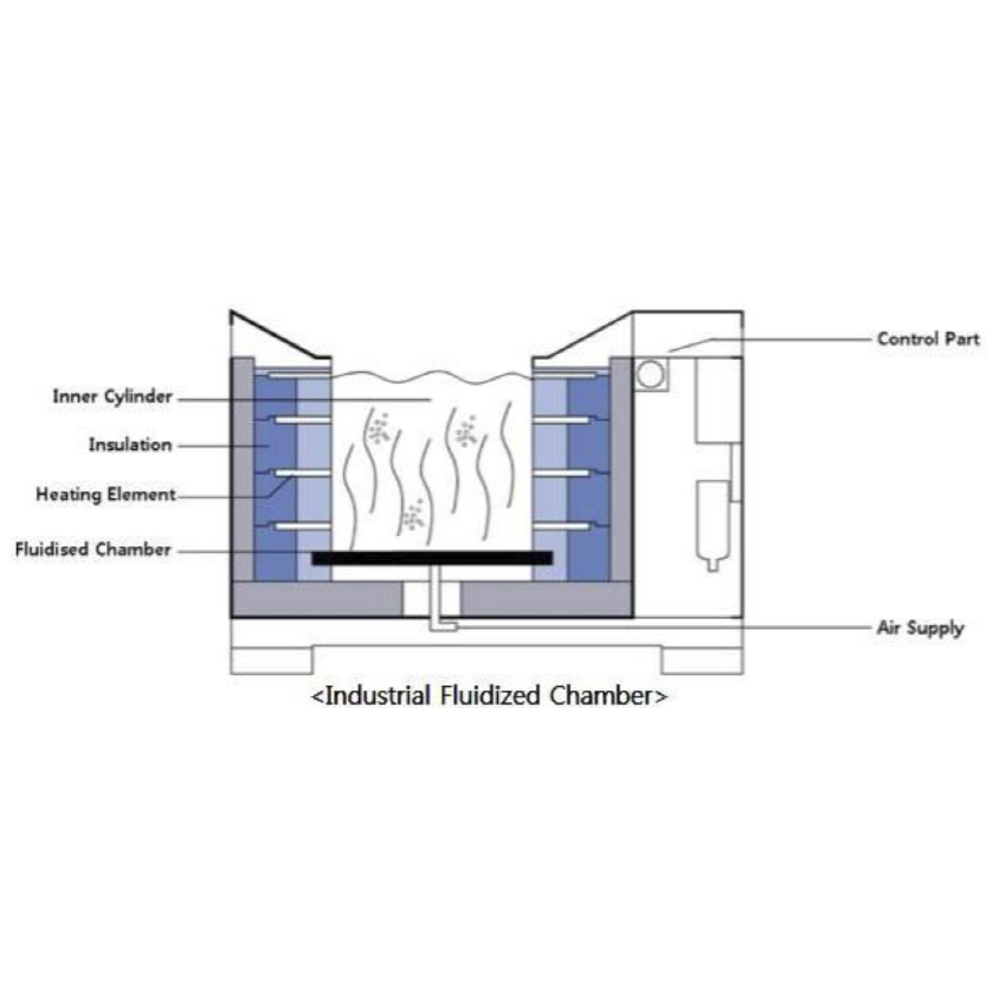

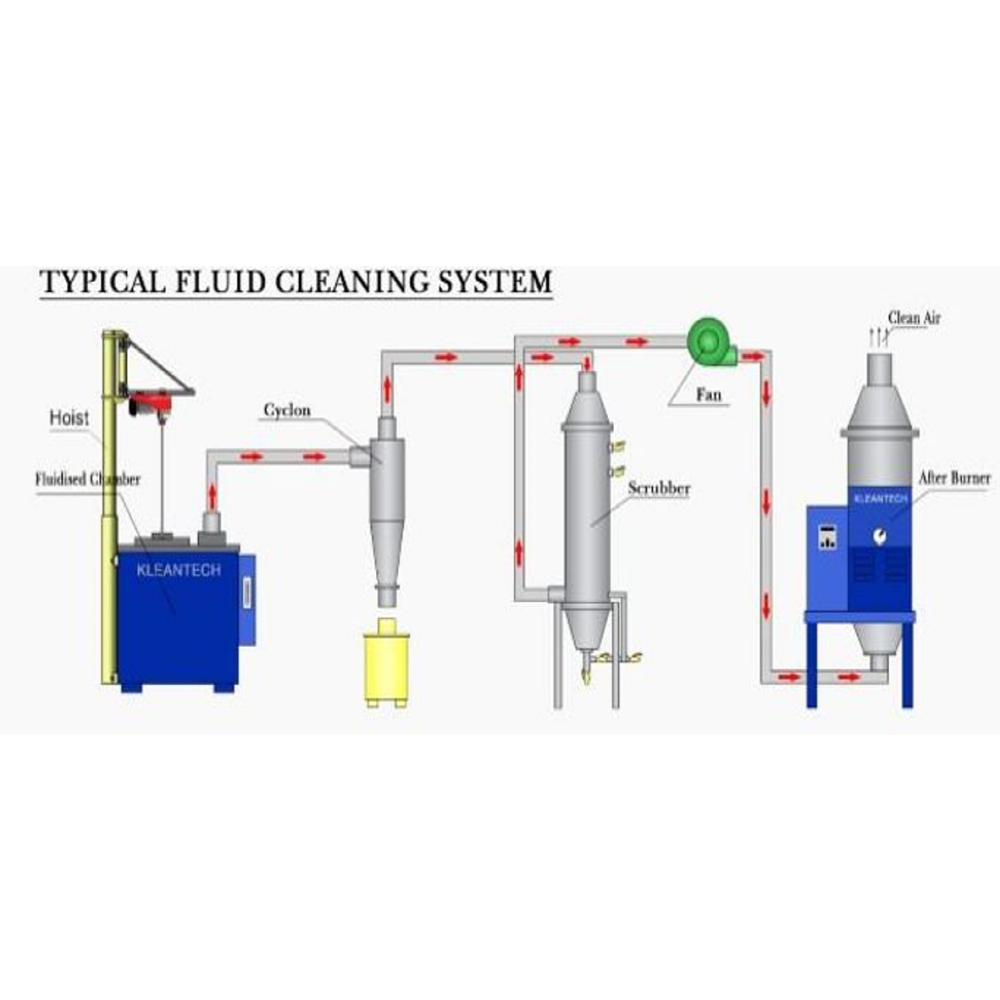

Principle of Operation

A fluidized chamber, filled with Thermal Medium, is heated to is heated to proper temperatures (400~500℃) and compressed air from Air Supply passes up in the particles(Thermal Medium) into "fluidized bed" of particle. The fluidized bed removes residues from metal parts and extruder hardware within 30 minutes. During cleaning items, the fluidized chamber may emit fumes. But a fume extraction system in Industrial Fluidized Bed Cleaning System eliminates fumes during the burning process.

*Thermal Medium is non-corrosive and non-abrasive and there is the addirional benefic that ir does not solidify when cooled, making the chamber easy to start up from room temperature.

The medium can be recycled many times after one cleaning process.

A fluidized chamber, filled with Thermal Medium, is heated to is heated to proper temperatures (400~500℃) and compressed air from Air Supply passes up in the particles(Thermal Medium) into "fluidized bed" of particle. The fluidized bed removes residues from metal parts and extruder hardware within 30 minutes. During cleaning items, the fluidized chamber may emit fumes. But a fume extraction system in Industrial Fluidized Bed Cleaning System eliminates fumes during the burning process.

*Thermal Medium is non-corrosive and non-abrasive and there is the addirional benefic that ir does not solidify when cooled, making the chamber easy to start up from room temperature.

The medium can be recycled many times after one cleaning process.

What is a FLUIDIZED BED?

"Fluidize Bed" is a bed which is in a state of fluidization. The state of fluifization is achieved when the individual particle of solids become microscopically separated from each other by the moving gas. This "fluidized bed" of particles has unusual properties which differ markedly from either those of the gas or of the solid particles. Instead, the fluidized bed behaves remarkably like a liquid state. A unique characteristic of fluidzed particles is the relatively high rate of heat transfer which yields highly isothermal condition, as well as excellent heat transfer to solid surfaces. The combination of rapid stabilization at an isothermal condition. Because of propertise of a fluidized bed, it is possible to control temperature easily in the chamber and to shorten one cleaning process time.

Application Field

Industrial Fluidized Bed Cleaning System is used for cleaning machine parts and tools contaminated with polymers and other things. Typical applications for the systems are shown in the table below. But, the cleaning ability of Industrial Fluidized Bed Cleaning System is not restricted to typical applications. Above all, please, contact us by phone and e-mail, to check applications.

"Fluidize Bed" is a bed which is in a state of fluidization. The state of fluifization is achieved when the individual particle of solids become microscopically separated from each other by the moving gas. This "fluidized bed" of particles has unusual properties which differ markedly from either those of the gas or of the solid particles. Instead, the fluidized bed behaves remarkably like a liquid state. A unique characteristic of fluidzed particles is the relatively high rate of heat transfer which yields highly isothermal condition, as well as excellent heat transfer to solid surfaces. The combination of rapid stabilization at an isothermal condition. Because of propertise of a fluidized bed, it is possible to control temperature easily in the chamber and to shorten one cleaning process time.

Application Field

Industrial Fluidized Bed Cleaning System is used for cleaning machine parts and tools contaminated with polymers and other things. Typical applications for the systems are shown in the table below. But, the cleaning ability of Industrial Fluidized Bed Cleaning System is not restricted to typical applications. Above all, please, contact us by phone and e-mail, to check applications.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Letter of Credit : L/C(sight)

- Name : YUMI Lee

SHIPPING

Shipping from :

Republic of Korea

- 64-4 Pulmugol-ro, Paju-si, Gyeonggi-do (10849)

YJSTECH CO., LTD.

The person in charge

Shin Hyung LeeAddress

64-4 Pulmugol-ro, Paju-si, Gyeonggi-do (10849)

Introduction

Dear prospective customers,

We are pleased to get this chance to introduce ourselves to you who might be our valuable

customers in the future. We have two business divisions. One is to manufacture industrial

cleaning machines. The other is trade business to sell our customers in the world.

• Industrial Molds and Dies Cleaning System

We have been focusing on Industrial Molds and Dies cleaning System for over 20 years. Now, we

manufacture the industrial fluidized cleaning system, which removes polymeric residues, coatings,

contaminations and other organic materials from metal parts and extruder hardware. We are

exporting the industrial fluidized cleaning system to many companies all over the world.

• Importer

We are one of the leading importers dealing with some kinds of test instruments that would be

handled most of the laboratories and the industrial fields, such as calibrators, micro-ohmmeters,

furnaces, water vapor testers, and so on.

Since 1979, we have endeavored to make our customers satisfied and gained a good reputation

as steady supplier of instruments of the highest quality and as the best manufacturer of industrial

cleaning machines. We will be a company that promises the best quality, accurate delivery and

reasonable prices with our long experience and field -.

Thank you for your attention and we sincerely look forward to serving you in the nearest future.

Best Regards,

-

- Business Type :

- Manufacturer

-

- Main Product :

- Industrial Molds and Dies Cleaning System , FLUKLEAN

-

- Established :

- 1997-01-27

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- 5~10 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

- 200

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- YJSTECH CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★