Rexva XiCA Carbon Film Heater(Heating Film)

-

Payment

L/C(sight)

-

MOQ

4,500 square metres(m2)

-

Supply Ability

300,000 square metres(m2) per One-Time

-

Supply Details

Customization

-

Country of sale

Asia, Americas, Europe, Middle East, Asia

-

PRICE

-

FOB

USD 2.00 ~ 3.10

(4,500 square metres(m2))

-

ITEM SPECIFICS

-

Brand

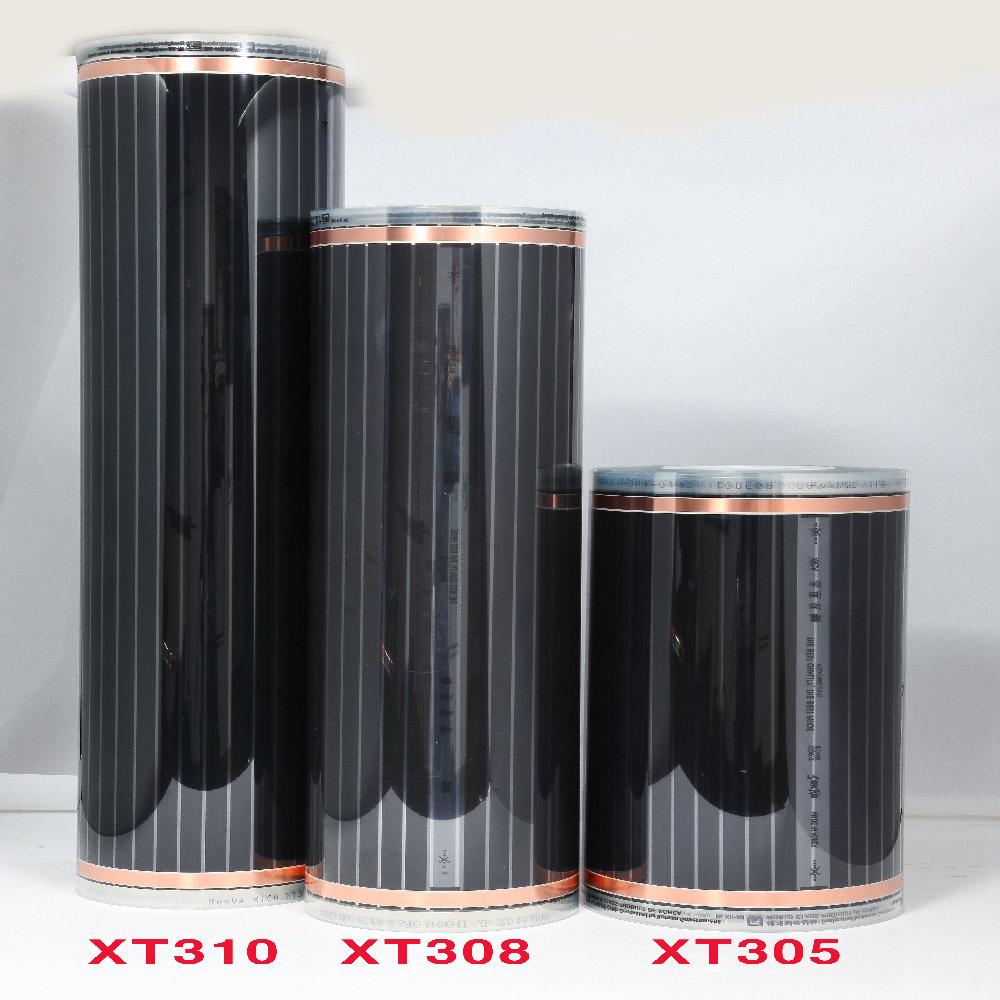

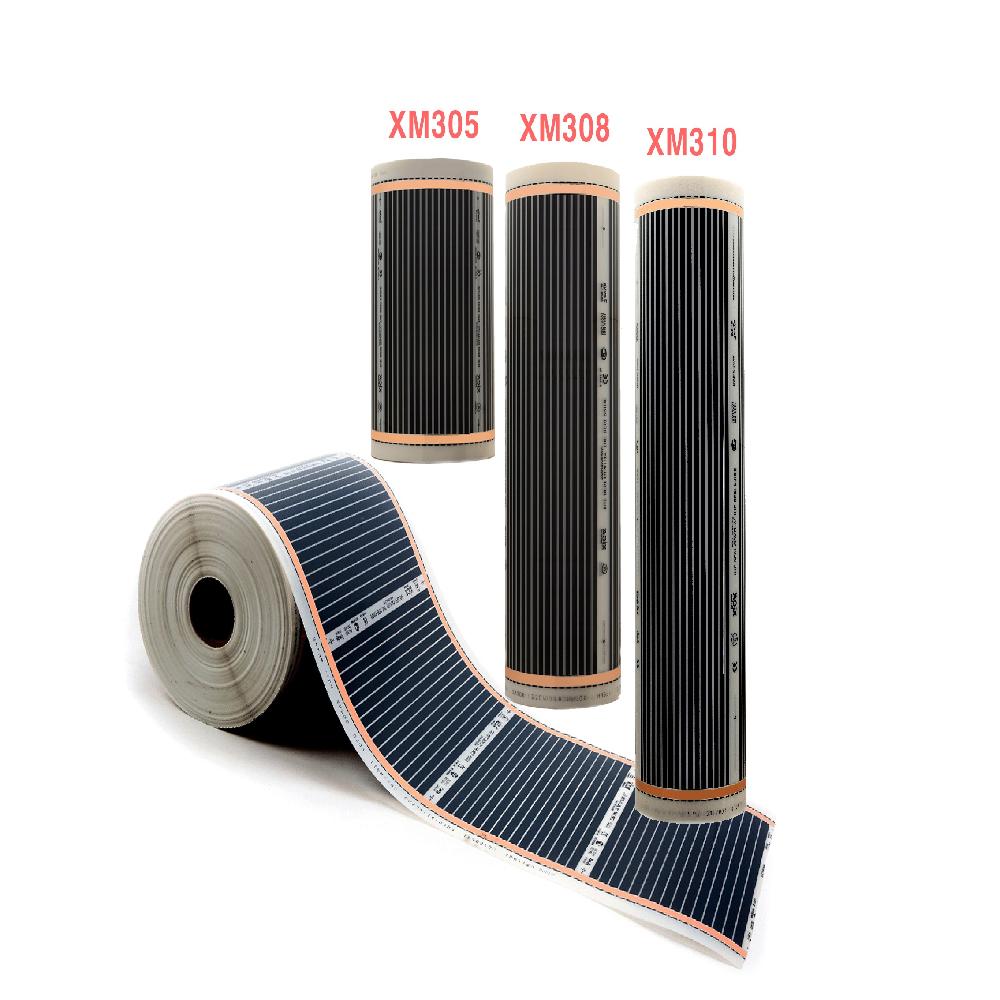

Model XM305, XM308, XM310, XT305, XT308, XT310XiCA

-

origin

Republic of Korea

-

Size(Capacity)

Depends on model

-

Weight

Depends on model

-

Color

Yellow, Green, Red, Milky, Transparent

-

Function

Under floor Warmming System all rooms can be controlled by one central thermostat.

-

Features

Under floor Warmming System all rooms can be controlled by one central thermostat.

PRODUCT DESCRIPTION

Overview of Xica Heating Film

XICA Heating Film is the most advanced face-shape far-infrared heating element unit which is made through the following processes of 1)applying carbon heating element to base film, 2)putting a thin coating made with activated carbon to absorb pollutants, 3)creating electrode with copper foil, 4)lastly making laminating process with film made from PET material.

Unlike regular heaters, carbon heating element are coated on the entire film which enables them to emit far-infrared radiation evenly. This is beneficial to your health making you feel the warmth of sunshine.

And also the exterior material of film heater is special fabric made of PET material and processed with special waterproof coating to avoid contacts with air, and thus the XICA Heating Film is a future-oriented heating material for wall, ceiling, and floor to be semi-permanently used.

The performance of heating film is dependant on the nano-particle dispersion technology made by cohesion and resistance of silver particles.

Effect of Xica Heating Film

- Far-infrared radiation heating

- rapid heating.

- keeps room evenly warm without any difference in room temperature between upper and lower part of the room.

- makes you enjoy comfortable heating effect even in a relatively low temperature of the room compared to convector. - Simple installation and easy workability

- Installation is much simpler than the wet mortar construction method.

- Installation can be completed simply by installing it between the insulation and the floor finish.

(* Be sure to install after taking the required heating film installation training course.) - Excellent durability

- It can be used semi-permanently.

- Its simple structure causes fewer failures. - Heating method without combustion.

- As a heating method without flames, it does not generate carbon monoxide, dust, and combustion noise.

- Good for facilities to be used by children, the elderly, and patients.

(kindergarten, nursery, senior's house, hospital, and so on.) - Quiet and clean heating.

- Heat generated by carbon emits a large amount of negative ions and far-infrared radiation.

- Far-infrared ray/negative ion : remove smell in the room and are very beneficial to the human body and create comfortable indoor air. - Excellent economical heating system.

- Cheaper by over 30% than electric heating and by over 60% than oil boiler.

- Construction can be completed within a very short time, Which reduces construction costs.

- Its area heating feature helps you save energy.

- Possible to be installed with an automatic control (central control) system.

Specification of Xica Heating Film

1) Available to meet order production with individual specification after considering safety of heating film.

2) Available to produce tin-plated booth bar to improve conductivity and to prevent oxidation.

Carbon Black of Xica Heating Film

Carbon black is a material containing carbon(C) like diamond as its main element is used for car, ink, and cosmetics. Depending on carbon's heat treatment temperature, we call it carbon fiber when performing heat-treatment at the temperature range of 1,000-3,000°C and graphite fiber when performing heat-treatment at the temperature of over 2,500°C.

Comparing with other materials, graphite has a very high heat resistance and a very low coefficient of thermal expansion and thus has an excellent thermal conduction and electrical conduction. As a result, this material is the most widely used for electrical heating element units.

* You can control adhesive force and resistance value depending on the mix ratio of carbon and graphite on carbon heating element band of heating film. (This is to use properties of circular molecular structure of carbon and planar structure of graphite.)

Silver Paste

- As a low-temperature type conductive for face-shape heating element, the conductive silver paste of XICA heating film possesses high conductive, characteristics of screen printing, flexibility, and also has excellent adhesion with P.E.T and Laminex.

| Measurement value | ||

| 1st | 2nd time | 3rd time |

| 0.1Ω/0.5cm | 0.1Ω/0.5cm | 0.1Ω/0.5cm |

Insulating Film Material of Xica Heating Film

| Section | Major Use |

Detailed Use |

Break Down Voltage |

UL Flame Retardant Certification |

Color | Price |

| Polyester Film |

for graphic | printing plates, label |

no measurement | null | transparent | cheap |

| for display | for display spreading plate |

no measurement | null | transparent | cheap | |

| for electricity/ electronics |

for wire cover, for insulation, for fire retardant |

Thickness 0.125mm-17KV, Thickness 0.188mm-19KV |

VTM-2 | adding insulation chip milky (semi-transparent) |

expensive |

* Be sure to use material for electricity and electronics for the material for film heating.

Durability Test of Xica Heating Film

- Experimental Institute : US AIC TECHNICA

- Experimental Period : April 25~May 22, 2009.

- Experimenter : Dr.Martin Peacoak (Director of Biotechnology and Materials Science)

Test 1. Conduct of Durability Test for Overvoltage and Over Heating

Durability test conducted by supplying voltage of 480v (exceeding designed power consumption by 23 times)to XICA Heating Film designed for 110V AC for about 30 minutes.

* XICA Heating Film has passed the durability test for sales in U.S. market by enduring the voltage of 480V (exceeding designed power consumption by 23 times) for 30 minutes and demonstrating heat-resisting force of about 170°C in above experiment.

Test 2. Test for Estimating Product Life Span

Check surface cracks of carbon heating element after testing repeatedly the following experiment for 24hours :

- Operate XICA Heating Film for 20minutes,

- Keep its film surface temperature at 40.5°C,

- Lower its film surface temperature to 0°C through the power block and rapid cooling.

Comparison Table by Construction Heating Method

| Section | Boiler | Far-infrared film heating | Remarks | |

| Construction method |

Construction method | wet possible | dry possible | freely |

| boiler room | necessary | unnecessary | more space required | |

| heat pipe | external exposure | none | clean | |

| construction thickness | 110~220mm | 10mm more or less | floor height increased by about 10cm. | |

| construction period | 4~5days | 1day | construction period shortening | |

| load/3.3m2 | about 240Kg | 2Kg | load reduction 238kg/3.3m2 | |

| Heating method | heating fuel | fossil fuel | electricity | not producing combustion, dust. gas. |

| heating method | conduction/convection | radiant heat | ||

| heating speed | 30~60 minutes | 4~10minutes | ||

| far-infrared ray | none | occur over 90% | ||

| Maintenance and Repair | maintenance | continually required | not required | convenient |

| A/S | often required | almost none | safe construction | |

| winter damage | occur | none | ||

| floor repair | major repair (concrete dissembling required) |

easy | simple | |

| cost | high (100%) | low(64%) | ||

| remodeling | plenty of restriction | easy | ||

| durability | 10 years more or less | semi-permanent | ||

How to Choose a High Quality Heating Film

| Heating film configuration |

Required functionality | Check point |

| Film (P.E.T. Film) |

thermal shrinkage when heating | check the width difference between base film and laminex film. |

| structure to prevent moisture penetration | check reflection on structure to prevent moisture penetration when designing film. | |

| adhesive property when exfoliating | check adhesive strength after exfoliating film. | |

| surface scratch | watch film surface and check film scratch to confirm insulation maintenance. | |

| insulation condition | check if film for insulation/flame-retardant is used. translucent film : for insulation and flame-retardant transparent film : for normal display |

|

| hardening | check if film surface is uneven. | |

| Copper Foil Booth Bar | copper foil width | foil is, The more current is allowed when applying electric current. |

| copper foil thickness | the thinner copper foil is, the less spark occurs to avoid widening gap between copper foil and film. | |

| type of copper foil | Electric conductivity : tough pitch copper (pure copper) : 106% Phosphorus-deoxidized copper : 86% |

|

| Dopping | even carbon surface | Check surface with more than 10 times magnifying glass. |

| spark-resistant design | When suffering overload on carbon printing surface, check if design reflects structure to prevent sparks. | |

| silver surface | When measuring electrical resistance of silver surface to prevent sparks, the lower resistance, the safer. (Ideal below 1-ohm) |

Precaution of Installation

- Clean the floor of the construction site before installing. Even the floor in order to prevent the heating film from bending or curving.

- Eliminate construction site's all moisture and dampness in order to prevent them from touching the film.

- Do not use glass fiber or heat insulator with ragged surface to prevent the damage on film's surface.

- Be careful neither to damage the surface of film nor step on it when installing them.

- For finish material, do not use paints that changes color or makes cracks when heated, coloring agents or hardening adhesives.

- Consult with specialist or construction contractor when installing heat insulator or finishing materials in order to maximize the heating efficiency.

- When cutting the film, make sure that length of the film do not exceed specified capacity of power consumption(Watt) and thermostat.

* Formula : Watt = V2R (V=Voltage, R=Resistance) - Consult with construction specialist or construction contractor for each construction site when installing other kinds of films.

- Please add 20% to the minimum expected heat rate when installing after considering various external environments, uses, and other environmental conditions.

Certificates Acquired By RexVa

| Type of Certificate | Certificate No. | Acquisition Date | Remarks |

| Korean Patent Registration | 10-0882702 | 2009-02-02 | Carbon paste printing device and its printing method |

| Korean Patent Registration | 10-0889195 | 2009-03-09 | Carbon paste composite for the face-shape heating element added with self-switch function |

| Korean Utility Model Registration | 20-0443373 | 2009-02-02 | Defrost Heaters for Unit Cooler |

| Trade make registration | 40-0745080 | 2008-04-29 | Registered the Trademark "RexVa" |

| Trade make registration | 40-0745081 | 2008-04-29 | Registered the Trademark "XICA" |

| UL/CUL | 20080807-E317480 | 2008-08-25 | USA/Canada Electrical Safety Certification |

| CE | CE-K-O421-O6 | 2006-04-21 | European Electrical Safety Certification |

| NRTL | CU 72070395 01 | 2007-02-22 | North American Electrical Safety Certification |

| GOST | POCC KR.BZ03.BO4115 | 2007-10-12 | Russian Electrical Safety Certification |

| UKRAINE STANDARD | UA 1.003.0020789-09 | 2009-04-13 | Ukraine Electrical Safety Certification |

| RoHS | The EU Restriction of the Use of Certain Hazardous Substances in Electrical & Electronic Equipment | ||

| Ukraine Safety Certification of Sanitary & Epidemiology | 05.03-02-03/20766 | 2008-04-10 | Ukraine Hygiene and Clinical Pathology Safety Certification |

| ISO 9001:2000 | 09-Q-1012-00 | 2006-05-29 | |

| ISO 14001:2004 | 09-E-0409-00 | 2008-05-06 | |

| Certificate of INNO-BIZ | 9061-1632 | 2008-08-06 | |

| Certificate of Venture Business | 20090201830 | 2009-04-27 | |

| Certificate of Export Promising Small & Medium Business | 09 Gyeonggi-50 | 2009-06-01 | |

| Gyeonggi Internet Trade Frontier Company | 2009-52 | 2009-04-01 | |

| Product Liability Insurance | 111120090001331-000 | 2009-05-10 | |

| KEL (CE Electromagnetic Testing) | KEL06-C03075 | 2006-04-04 | |

| Far Infrared Test Report | KFI-386 | 2007-05-21 | |

| Negative Ion Test Report | KFI-253 | 2007-05-21 | |

| Gyeonggi Promising Small & Medium Business | 2009-211 | ||

| Certificate of Clean Business Plac | 54,507 | 2009-08-17 |

R&D CERTIFICATE

-

- CE

- CCQS UK LTD

- 20140513

- 인증서보기

-

- UL

- UL LLC

- 20070222

- 인증서보기

-

- SASO

- TUV AUSTRIA

- 20190617

- 인증서보기

-

- EAC

- ROSTEST

- 20200214

- 인증서보기

-

- China Trade Mark Rexva

- SAIC

- 20161021

- 인증서보기

-

- Korea Trade Mark Rexva

- KIPO

- 20080429

- 인증서보기

-

- Korea Trade Mark XICA

- KIPO

- 20080429

- 인증서보기

-

- Russia Trade Mark Rexva

- FSIS

- 20130901

- 인증서보기

-

- Turkey Trade Mark Rexva

- TPM

- 20191112

- 인증서보기

-

- Turkey Trade Mark XICA

- TPM

- 20191112

- 인증서보기

-

- IEC 60335-2-96 Test report

- CTS

- 20190425

- 인증서보기

PAYMENTS DETAILS

- Letter of Credit : L/C(sight)

- Name : Henry Kim

SHIPPING

- 173beon-gil Geomsan-ro (10848)

- Air Cargo : Please contact us for inquiry on carriers

- Sea Freight : Please contact us for carriers inquiry

- Land Transportation

- Air Cargo : DHL Possible

- Sea Freight : possible

- Please contact your administrator for detailed information.

- Name : Ho Sup,Kim

- Tel : 82-31-949-7860

The person in charge

Ho Sup KimAddress

173beon-gil Geomsan-ro, Paju-si, Gyeonggi-do (10848)

렉스바

-

- Business Type :

- Manufacturer

-

- Main Product :

- heating Film(Underfloor warmming)

-

- Established :

- 2006-04-01

-

- Total Annual Revenue :

- 6~7 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- CE

- CCQS UK LTD.

- 20140513

- 인증서보기

-

- China Trade Mark Rexva

- SAIC

- 2016.10.21

- 인증서보기

-

- Korea Trade Mark XiCA

- KIPO

- 2008.0429

- 인증서보기

-

- ChineTrade Mark

- SAIC

- 20161021

- 인증서보기

-

- UL

- UL LLC

- 18112019

- 인증서보기

-

- SASO

- TUV AUSTRIA

- 17062019

- 인증서보기

-

- EAC

- ROSTEST

- 14022020

- 인증서보기

-

- China Trade Mark Rexva

- SAIC

- 21102016

- 인증서보기

-

- Korea Trade Mark Rexva

- KIPO

- 29042008

- 인증서보기

-

- Korea Trade Mark XICA

- KIPO

- 29042008

- 인증서보기

-

- Russia Trade Mark Rexva

- FSIS

- 01092013

- 인증서보기

-

- China Trade Mark Rexva

- SAIC

- 2016.10.21

- 인증서보기

-

- CE

- CCQ UK LTD

- 20140513

- 인증서보기

-

- SASA

- TUV AUSTRIA

- 20190617

- 인증서보기

-

- Korea Trade Mark Rexva

- KIPO

- 2008.04.29

- 인증서보기

-

- Korea Trade Mark XICA

- KIPO

- 2008.04.29

- 인증서보기

-

- Russia Trade Mark Rexva

- FSIS

- 2013.09.01

- 인증서보기

-

- Russia Trade Mark Rexva

- FSIS

- 30130901

- 인증서보기

-

- China Trade Mark Rexva

- SAIS

- 20161021

- 인증서보기

-

- CE

- CCQS UL LTD

- 20140513

- 인증서보기

-

- China Trade Mark Rexva

- SAIC

- 20080429

- 인증서보기

-

- Russia Trade Mark Rexva

- FSIS

- 20130901

- 인증서보기

-

- CE

- CCQS UK LTD

- 20140513

- 인증서보기

-

- UL

- UL LLC

- 20070222

- 인증서보기

-

- SASO

- TUV AUSTRIA

- 20190617

- 인증서보기

-

- EAC

- ROSTEST

- 20200214

- 인증서보기

-

- China Trade Mark Rexva

- SAIC

- 20161021

- 인증서보기

-

- Korea Trade Mark Rexva

- KIPO

- 20080429

- 인증서보기

-

- Korea Trade Mark XICA

- KIPO

- 20080429

- 인증서보기

-

- Russia Trade Mark Rexva

- FSIS

- 20130901

- 인증서보기

-

- Turkey Trade Mark Rexva

- TPM

- 20191112

- 인증서보기

-

- Turkey Trade Mark XICA

- TPM

- 20191112

- 인증서보기

-

- TUV NORD

- TUV NORD KOREA LTD

- 20110602

- 인증서보기

-

- CE

- Rexva

- 20190527

- 인증서보기

-

- IEC 60335-2-96 Test report

- CTS

- 20190425

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 6~7 billion (KRW)

-

- Total export revenue (previous year in USD)

- 700

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- REXVA CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★