Cross Roller Guide

-

Payment

L/C(sight) , OT , T/T

-

MOQ

10 ea

-

Supply Ability

1,000 ea per Month

-

Supply Details

Customization

Depend on quantity

-

Country of sale

World Wide, World Wide, World Wide, World Wide, World Wide

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model MVR seriesMid

-

origin

Republic of Korea

-

Size(Capacity)

5 x 10 x 13

-

Color

Block and White

-

Material

Steel Juj2

-

Weight

200g

-

Function

Linear guide instrument

PRODUCT DESCRIPTION

[Features]

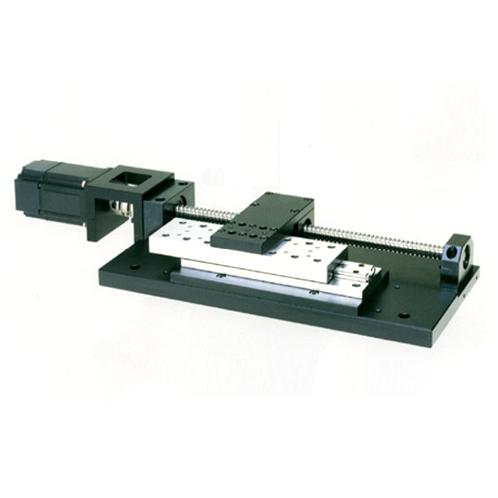

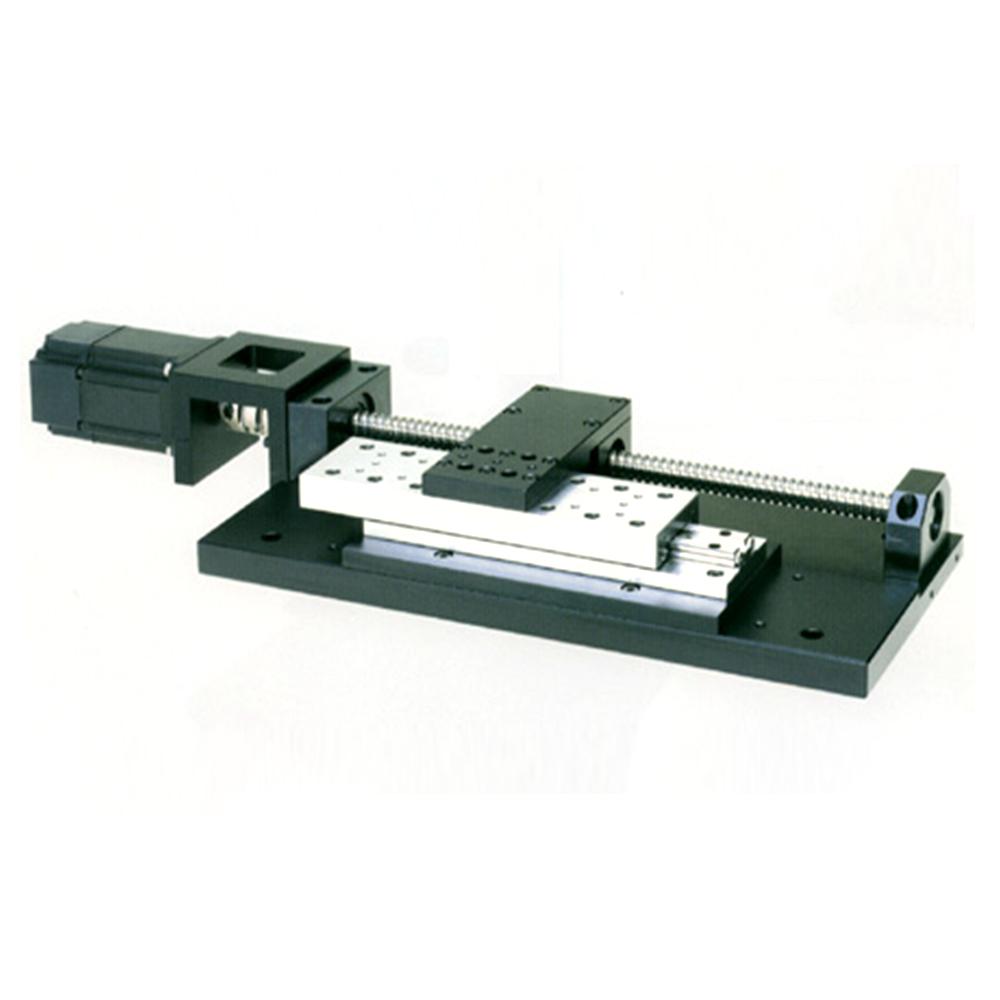

Cross Roller Linear Guide

Our Cross Roller Guide MVR.MVRM type are a linear guide instrument by assembling cage actively between two-patterned obtiting planes after making V-shaped two-surcafes as an orbiting groove. it is a highly rigid and precise linear motion system of limitted type since rollers are arranged orthogonally so it may receive load from various directions. There are various kinds to choosen from.it is in a wide range of application in precision equipments such as OA instruments and peripherals,or in slide such as optical meter,optical stage,and handling equipments.

Cross Roller Rotary Guide

With the cross troller rotary guide,cylindrical rollers are arranged with each roller perpendicular to the adjacent roller,in a 90 degree V groove,separated from each other by a spacer retainer. This design allows just one bearing to receive loads in all directions including radial,axial and mount loads,Since the cross roller rotary guide achieves high rigidity despite the minium posssible dimensions of the inner and outter rings,it is optimal for applications such as joints and swiveling units of industrial robots,swiveling tables of mchining centers,precision rotary table,medical equipments,measuring instruments and IC manufacturing machines.

Miniature Ball Slide Pack

Our miniature ball slide pack MBSP is of light weight,compact and bearing guide straight-line motion bearing integrating the orbiting part and the base and forming in U-shape made of stainless steel plate.As the part can remains stable while maintaining its high performance and quality for a long time,it is widely used as a functional component for precision instrument for precision straight-line montion.Plus the user can choose appropriate form as it comes in various size and performance

Cross roller guide MVR-type is used by combining roller cage, which is assembled by arranging precision roller orthogonally, with the roller surface of 90V groove which is manufactured onto its specialized rail. Since double-range roller guide is attached horizontally, the load from all directions passing through the axle at a right angle can be received.

• High ridigity

There is no clearance since applying preload is quite simple. Furthermore, the contact length between the roller and the contact plane is long so that high rigitidy can be obtained.

• Soft motion

MID cross roller guide MVR-type is at an orbiting surface of high precision. Plus, the roller with no skew phenomenon and accurate maintanance for its size is assembled into the cage, so that soft rolling motion with low rolling resistance without stick-slips can be acquired.

• Easy to fix

Fixing holes in the orbiting plane are manufactured with counter and tap process. For fixing onto the orbiting plane, thus, there are two methods; the one is to fix it onto the tapof machine and installments. The other is to push the bolt from the machine and equipments and fix it. So there's no limitation to the fixingstructure. Since orbiting plane has uniform structure of two-patterned orbiting planes in the inside, fixingstructure is quite simple. Therefore, there is no manufacturing error in fixingpart and linear motion of high precision can be obtained.

[Specifications]

Standard size

Precision of a rail specialized for cross roller guide is classified into highly superior group and precision group according to (Table1).

Packaging & Delivery

• Packing : Export Standard

• Delivery Lead Time : Promptly after Order

• Minimum Order : 20 sets

• Supply Ability : 10000 per month

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : Wo Ho Lee

SHIPPING

Shipping from :

Republic of Korea

- 15 Gyeongin-ro 53-gil, Guro-gu, Seoul (08217)

KLS(Korea Lintec & Shaft)

The person in charge

Wo Ho LeeAddress

15 Gyeongin-ro 53-gil, Guro-gu, Seoul (08217)

Introduction

Greetings to customers all around the world! Our company have been producing all sorts of shafts and exporting to the international market. Our brand "KLS" Shaft (Korea Lintec & Shaft) has been acknowledged for great quality control, competitive pricing, and punctual and fast delivery. Exports have been increasing continuously due to our excellent reputation of great deals and quality by our customers. Especially, we have developed HPJ Brand's LM Bushings overseas (China), of which trademark HPJ has registered in Japan, which is used with our Shaft and we are exporting them in parallel, and has established ourselves as a maker of LM System.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Cross Roller Guide, Miniature Linear GuideSmall LM Guide, Support Unit for Ball Screw, Shaft for Ball Bushings Bearings, RodEnd Camfollower and Track Rollers

-

- Established :

- 2002-08-02

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- Less than 5

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

- 1

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- KLS(Korea Lintec & Shaft) Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★