ITEM SPECIFICS

-

Brand

Model BK,FK,BF,FFDS

-

origin

Ghana

-

Size(Capacity)

30 x 25 x 30mm

-

Function

Rolling

-

Color

Black

-

Weight

300g

-

Material

STKMC45

PRODUCT DESCRIPTION

[Features]

Characteristics of KLS Supports Units

Structure

The support unit for fixture part is assembled by angular ball bearing with high rigidity and low torque in face-to-face duplex format that is appropriate to the dynamic property of rotation shaft. In addition, it can achieve highly accurate rotation capability through precise adjustment on preload. the support unit for support part uses deep groove ball bearing. There is oil seal x-framed in the unit, and it prevents the grease from leaking. It prevents the influx of fine dusts or foreign substances and allows longtime use.

The support unit for fixture part is assembled by angular ball bearing with high rigidity and low torque in face-to-face duplex format that is appropriate to the dynamic property of rotation shaft. In addition, it can achieve highly accurate rotation capability through precise adjustment on preload. the support unit for support part uses deep groove ball bearing. There is oil seal x-framed in the unit, and it prevents the grease from leaking. It prevents the influx of fine dusts or foreign substances and allows longtime use.

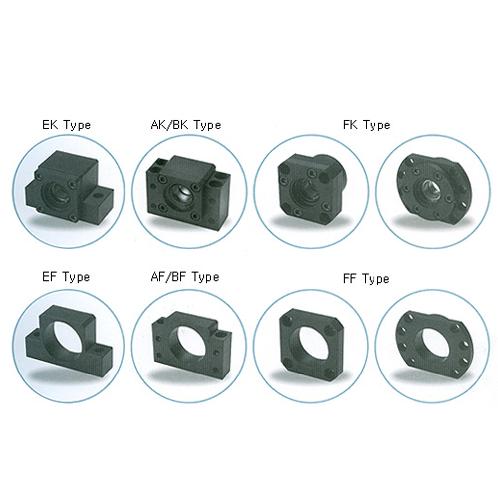

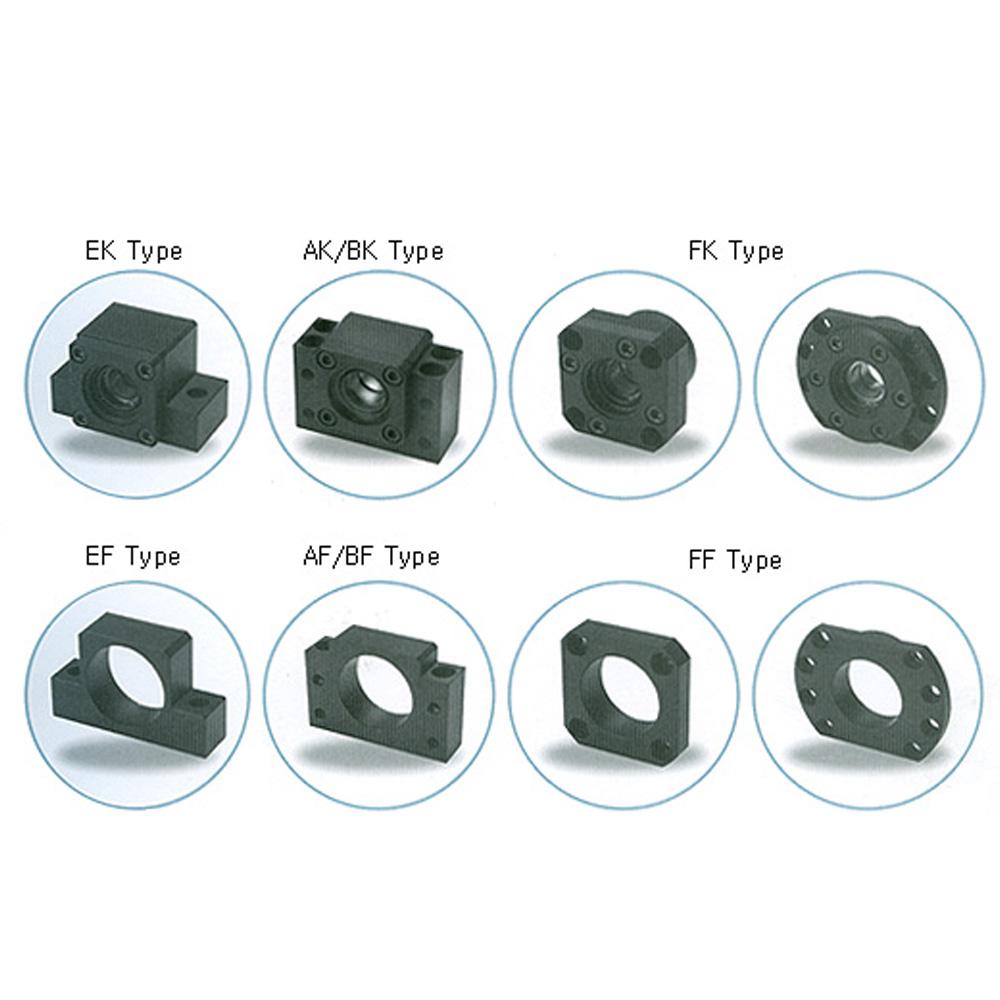

Shape and Classification

There are two types of units that are available for different conditions of installation and use. One employs angle type(block type) structure where the unit is fixed on the base surface, and the other employs round type(flange type) structure where the unit is inserted into a hole for fixation. The unit is also divided into two parts depending on the position of power transmission shaft - the part for support on the other side.

• Simplicity of Design and Assembly

Standardization of product allows highly effective design. Additional assembly process is not required, and the stability of assembly precision can be easily improved as bearing of the support unit is assembled at optimal preload condition. Moreover, the standardized product ensures superior compatibilty.

Standardization of product allows highly effective design. Additional assembly process is not required, and the stability of assembly precision can be easily improved as bearing of the support unit is assembled at optimal preload condition. Moreover, the standardized product ensures superior compatibilty.

• High Precision

Angular contact ball bearing is precisely assembled in face-to-face duplex format. The influence by assembly error is minimized and the precision of rotation shaft is maintained as the product structure is designed to absorb parallel error between rotational shaft and guide about the center of the shaft.

Angular contact ball bearing is precisely assembled in face-to-face duplex format. The influence by assembly error is minimized and the precision of rotation shaft is maintained as the product structure is designed to absorb parallel error between rotational shaft and guide about the center of the shaft.

• Dust-Proof Effect

The support unit is x-framed with oil seal to prevent the influx of fine dusts or foreign substances and thus enhances operation precision. Furthermore, it allows longtime use as grease leakage is prevented by minimizing the tolerance between the oil seal and the rotation shaft.

The support unit is x-framed with oil seal to prevent the influx of fine dusts or foreign substances and thus enhances operation precision. Furthermore, it allows longtime use as grease leakage is prevented by minimizing the tolerance between the oil seal and the rotation shaft.

[Applications]

How to use

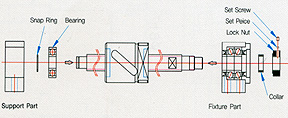

Steps to install the Support unit

1. Assemble to Support Units

|

1)Connect the unit for fixture part to ball screw

.It is not allowed to dissemble the unit as its preload has been already controlled .The wing part of the oil seal should bot be folded when ball screw is inserted into the unit. 2)After inserting the ball screw into the unit, put the collar and couple and adjust the locknut. Then place the set piece in the stop screw part of the locknut and tighten the stop screw.

.Adhesive can be used to prevent the locknut from being loosened 3)Mount the nut bracket on ball screw.

4)After connecting the unit ball bearing for support part to the ball screw, fix the snap ring and assemble to the housing.

|

|

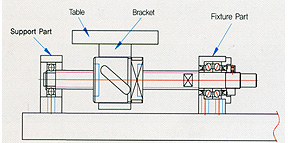

2. Assemble to Table and Base

|

1)Connect table to the nut bracket of ball screw.

2)Preassemble the support unit for fixture part to the designed position of the base.

.When the unit for fixture part is the standard, adjust to have clearance in external diameter of the nut and internal diameter of the table or bracket. .When the table is the standard, adjust the height of angle type unit. For flange type, adjust to have clearance in external diameter and internal diameter. 3)Connect the unit housing for support part to ball screw and preassemble to the designed position of the base.

|

|

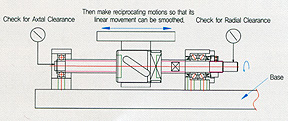

3. Precision of Rotation Shaft and Coupling

|

1)Move the table connected to the ball screw toward the center of the shaft in order to place the center of the shaft properly. Make alternating motion so that its linear movement can become smooth.

2)While measuring the tolerance toward the direction of the shaft and the vibration at the end of the rotational shaft of the ball screw, measure the center of the shaft and couple in the order of nut bracket and table, the unit for fixture part, the unit for support part and base.

|

|

4. Drive Motor and Assembly

|

1)Precisely connect the bracket installed on the motor to the base by matching it with the shaft center of the ball screw.

2)Connect the coupling to the motor and the shaft for fixture part.

.Careful attention is necessary during assembly as the assembly condition of the motor bracket and the coupling affects the positioning of table. 3)Check the precision of the shaft center by conducting enough test operation while driving the motor at slow speed.

|

|

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : Wo Ho Lee

SHIPPING

Shipping from :

Republic of Korea

- 15 Gyeongin-ro 53-gil, Guro-gu, Seoul (08217)

KLS(Korea Lintec & Shaft)

The person in charge

Wo Ho LeeAddress

15 Gyeongin-ro 53-gil, Guro-gu, Seoul (08217)

Introduction

Greetings to customers all around the world! Our company have been producing all sorts of shafts and exporting to the international market. Our brand "KLS" Shaft (Korea Lintec & Shaft) has been acknowledged for great quality control, competitive pricing, and punctual and fast delivery. Exports have been increasing continuously due to our excellent reputation of great deals and quality by our customers. Especially, we have developed HPJ Brand's LM Bushings overseas (China), of which trademark HPJ has registered in Japan, which is used with our Shaft and we are exporting them in parallel, and has established ourselves as a maker of LM System.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Cross Roller Guide, Miniature Linear GuideSmall LM Guide, Support Unit for Ball Screw, Shaft for Ball Bushings Bearings, RodEnd Camfollower and Track Rollers

-

- Established :

- 2002-08-02

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- Less than 5

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

- 1

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- KLS(Korea Lintec & Shaft) Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★