- Health & Beauty Protective Items Health & Medical Beauty & Personal Care

- Bags, Shoes & Accessories Luggage, Bags & Cases Shoes & Accessories

- Apparel, Textiles & Accessories Apparel Textile & Leather Product Fashion Accessories Timepieces, Jewelry, Eyewear

- Electronics Industrial Computer & Accessories Home Appliance Consumer Electronic Security & Protection

- Electronic Equipment, Component & Telecoms Electronic Equipment & Supplies Telecommunication

- Home, Lights & Construction Construction & Real Estate Home & Garden Lights & Lighting Furniture

- Gifts, Sports & Toys Gifts & Crafts Toys & Hobbies Sports & Entertainment

- Agriculture & Food Agriculture Food & Beverage

- Auto & Transportation Automobiles & Motorcycles Transportation

- Machinery, Industrial Parts & Tools Machinery Industrial Parts & Fabrication Services Tools Hardware Measurement & Analysis Instruments

- Metallurgy, Chemicals, Rubber & Plastics Minerals & Metallurgy Chemicals Rubber & Plastics Energy Environment

- Packaging, Advertising & Office Packaging & Printing Office & School Supplies Service Equipment

- K-Service Innotech Contents ICT Technology/Engineering

- ETC ETC

ITEM SPECIFICS

-

Brand

Model Special(Nickel) Alloy WiresKOWEL

-

origin

Republic of Korea

-

Size(Capacity)

Depending on the requirements

-

Material

Alloy wire

-

Weight

Depending on the packing specification

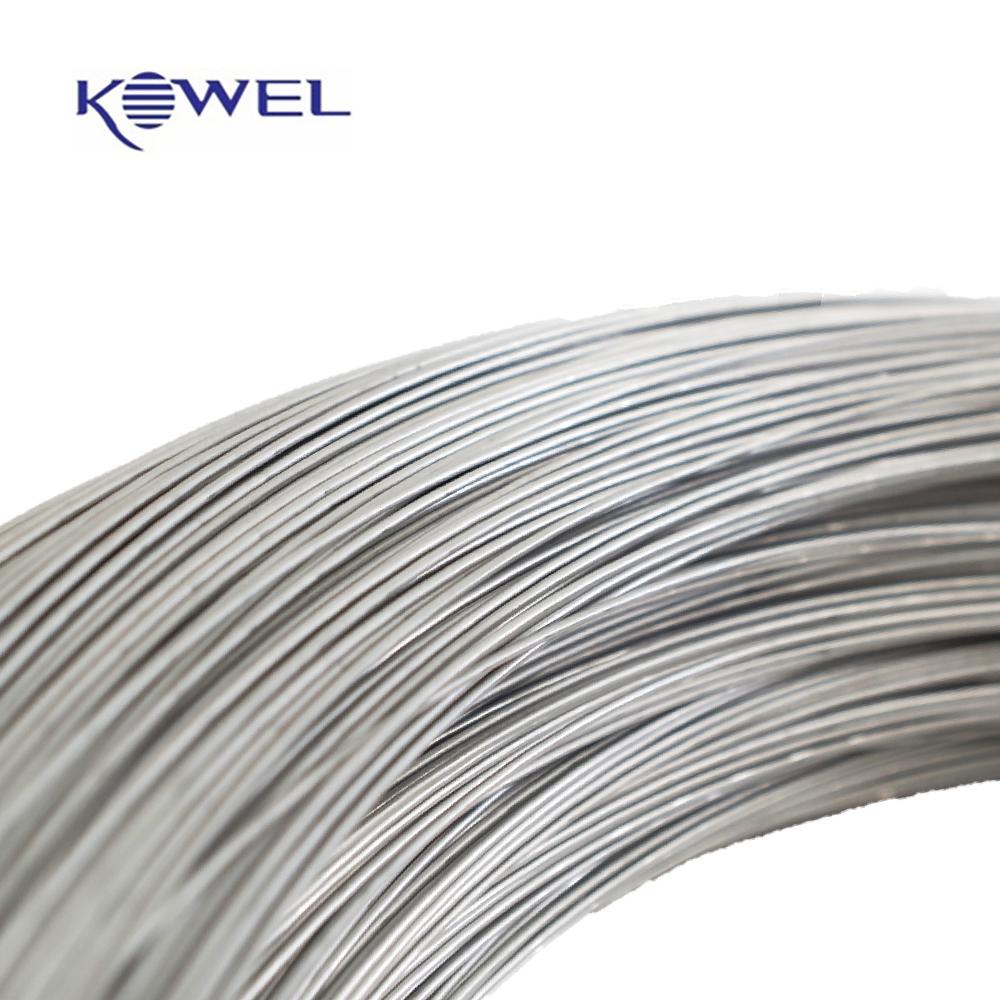

PRODUCT DESCRIPTION

[Features]

We offer approximately 20 kinds of special alloy wire with

exceptional corrosion resistance and heat resistance to customers

Types of Special Alloy Wire (Specification)

Grade Characteristic

Alloy601 - High Temperature Strength, Resistance AgainstOxidation, Carbonization, (N06601) Nitrification

- Stress and Corrosion Resistance at Room/High Temperature Condition

- Chlorine Resistance in Dry Chloric Environment

Alloy601 - High Temperature Strength, Resistance AgainstOxidation, Carbonization, (N06601) Nitrification

- Stress and Corrosion Resistance at Room/High Temperature Condition

- Chlorine Resistance in Dry Chloric Environment

C 0.10, Mn 1.00, Fe Rem, P 0.03, S 0.015, Si 0.50, Cu 1.00,

Cr 21.5, To 25.0, Ni 58.0 To 63.0 ,Al 1.0 To 1.7, Etc 0.50

Alloy625 - Low/High Temperature Strength, High resistance against Corrosion

(N06625) and Oxidation

- Guarantee high tensile strength & elongation, Oxidation resistance,

and Fatigue strength from extremely low temperature to high

temperature, 980℃

- Excellent resistance against corrosion cracking

- Excellent resistance against Chlorine condition

- Excellence in corrosion resistance against such Acid condition as Nitric,

Phosphoric, Sulfuric

- Excellence in corrosion resistance against such condition as Organic Acid

and Alkalinity

(N06625) and Oxidation

- Guarantee high tensile strength & elongation, Oxidation resistance,

and Fatigue strength from extremely low temperature to high

temperature, 980℃

- Excellent resistance against corrosion cracking

- Excellent resistance against Chlorine condition

- Excellence in corrosion resistance against such Acid condition as Nitric,

Phosphoric, Sulfuric

- Excellence in corrosion resistance against such condition as Organic Acid

and Alkalinity

C 0.10 Mn 1.00 Fe 5.00 P 0.02 S 0.015 Si 0.50 Cu 0.50

Cr 20.0 To 23.0 Ni 58.0min Al 0.40 Ti 0.40 Mo 8.0 To 10.0 Etc 3.65 To 4.65

Alloy 718 - Low/High Temperature Strength, High resistance against Corrosion

(N07718) and Oxidation

- High Tensile Strength up to temperature, 700℃ condition

- High Oxidation resistance up to temperature, 1,000℃ condition

- High resistance against Stress Corrosion

- Excellent Arc. Weldability

(N07718) and Oxidation

- High Tensile Strength up to temperature, 700℃ condition

- High Oxidation resistance up to temperature, 1,000℃ condition

- High resistance against Stress Corrosion

- Excellent Arc. Weldability

C 0.08 Si 0.35 Mn 0.35 Al 0.2 To 0.8 Ti 0.65 To 1.15 Ni 50 To 55

Cr 17 To 21 Cu 0.3 Mo 2.8 To 3.3 Fe Bal Nb+Ta 4.75 To 5.5 Etc -

Alloy C276 - High Corrosion Resistance, Intergranular Corrosion Resistance,

(N10276) Friction Wearing Resistanc

- High Resistance in Oxidation & Reducing Environment

- High resistance against Stress Corrosion and Cracks

(N10276) Friction Wearing Resistanc

- High Resistance in Oxidation & Reducing Environment

- High resistance against Stress Corrosion and Cracks

C 0.02 Mn 1.00 Fe 4.0 To 7.0 P 0.04 S 0.03 Si 0.08 Cu 0.50

Co 2.50 Cr 14.5 To 16.5 Ni Rem Mo 15.0 To 17.0 Etc 3.85 To 5.35

Alloy X750 - High resistance against Corrosion and Oxidation at High temperature

(-) condition

- Aging and Thermosetting (Thermohardening) Alloy excellent in Corrosion

& Oxidation resistance

- Guarantee Tensile Strength in high level up to temperature, 600℃

- High Creep Strength

- High Stress Endurance

(-) condition

- Aging and Thermosetting (Thermohardening) Alloy excellent in Corrosion

& Oxidation resistance

- Guarantee Tensile Strength in high level up to temperature, 600℃

- High Creep Strength

- High Stress Endurance

C 0.08Max Mn 0.35Max Fe 8.00 Si 0.35max Co 1.00max Cr 16.0

Ni 70.00 Al0.80 Ti 2.5 Etc 1.00

Alloy 400 - High corrosion resistance, High weldability and high strength

(N04400) - resistance to a variety of corrosive conditions

- Application : valves and pumps; pump and propeller shafts; marine fixtures

and fasteners; electrical and electronic components; springs; chemical

processing equipment; gasoline and fresh water tanks; crude petroleum stills,

process vessels and piping; boiler feedwater heaters and other heat

exchangers; and deaerating heaters.

Alloy 400 - High corrosion resistance, High weldability and high strength

(N04400) - resistance to a variety of corrosive conditions

- Application : valves and pumps; pump and propeller shafts; marine fixtures

and fasteners; electrical and electronic components; springs; chemical

processing equipment; gasoline and fresh water tanks; crude petroleum stills,

process vessels and piping; boiler feedwater heaters and other heat

exchangers; and deaerating heaters.

C 0.3max Mn 2.0max Fe 2.5max S 0.024max Si 0.5Max 28 To 34 Ni 63min Etc 0.025 To 0.060

Alloy 693 - High resistance against Corrosion and Oxidation at High temperature

(N06693) condition

(-) - good resistance to sulfidation in both oxidizing and reducing

environments containing sulfur

- Guarantee Tensile Strength in high level up to temperature, 1100℃

C 0.15 Mn 1.00 Fe 2.5 To 6.0 P 0.03 S 0.01 Si 0.50 Cu 0.50

(N06693) condition

(-) - good resistance to sulfidation in both oxidizing and reducing

environments containing sulfur

- Guarantee Tensile Strength in high level up to temperature, 1100℃

Cr 27.0 To 31.0 Ni Rem Al 2.5 To 4.0 Ti 1.00 Etc 1.0 To 4.0

WASPALOY - good strength at temperatures up to about 980°C.

(-) - material for forged and fabricated gas turbine and aerospace components

- High Resistance in Oxidation & Reducing Environment

C 0.008Max Mn 0.10Max Fe 2.00Max Co 13.50Max Si 0.15Max (-) - material for forged and fabricated gas turbine and aerospace components

- High Resistance in Oxidation & Reducing Environment

Cu 0.1Max Cr 19.0 Ni 58.00 Al 0.015Max Ti 3.00 Mo 4.30 Etc 0.056

[Packing]

standardization and packing specifications for special packages can be

changed according to customer request, and can be ordered separately.

Wire Cond Dia(mm) Unit package Innerside Packing Outerside Packing

Soft 0.10 ~ 0.14 DIN 100 Spool Carton Box Cardboard Box

0.15 ~ 0.18 DIN 125 Spool or

0.19 ~ 0.35 DIN 160 Spool Wooden Case

DIN 200 Spool

DIN 250 Spool

DIN 355 Spool

0.71 ~ 1.99 12” 16” 24” Coil/Pail P.P Cloth Cardboard Box

2.00 ~ 5.25 24” Coil/Carrier Bundle with P.P Cloth

Soft 0.10 ~ 0.14 DIN 100 Spool Carton Box Cardboard Box

0.15 ~ 0.18 DIN 125 Spool or

0.19 ~ 0.35 DIN 160 Spool Wooden Case

DIN 200 Spool

DIN 250 Spool

DIN 355 Spool

0.71 ~ 1.99 12” 16” 24” Coil/Pail P.P Cloth Cardboard Box

2.00 ~ 5.25 24” Coil/Carrier Bundle with P.P Cloth

Wire Cond Dia(mm) Unit package Innerside Packing Outerside Packing

Hard 0.10 ~ 0.30 DIN 100 Spool Carton Box Cardboard Box

0.30 ~ 0.60 DIN 125 Spool Wooden Case

DIN 160 Spool

DIN 200 Spool

DIN 250 Spool

DIN 355 Spool

0.61 ~ 0.99 8” 10” 12” Coil P.P Cloth Cardboard Box

1.00 ~ 1.99 12” 14” 18” 24” Coil P.P Cloth Cardboard Box

2.00 ~ 15.00 24” 32” Coil/Carrier Bundle with P.P Cloth

Hard 0.10 ~ 0.30 DIN 100 Spool Carton Box Cardboard Box

0.30 ~ 0.60 DIN 125 Spool Wooden Case

DIN 160 Spool

DIN 200 Spool

DIN 250 Spool

DIN 355 Spool

0.61 ~ 0.99 8” 10” 12” Coil P.P Cloth Cardboard Box

1.00 ~ 1.99 12” 14” 18” 24” Coil P.P Cloth Cardboard Box

2.00 ~ 15.00 24” 32” Coil/Carrier Bundle with P.P Cloth

Packing specifications can be changed according to customer request.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Chang-won, Sung

SHIPPING

Shipping from :

Republic of Korea

- 5 Sanmakgongdanbuk 4-gil, Yangsan-si, Gyeongsangnam-do (50567)

KOWEL Co., Ltd.

The person in charge

Chang-Won SungAddress

5 Sanmakgongdanbuk 4-gil, Yangsan-si, Gyeongsangnam-do (50567)

Introduction

"It is our great honor to have a precious chance to introduce our company, KOWEL Co., Ltd.

Since we established on the 08th Oct. 1982,

we have been surviving in the hectic changing atmosphere of all kinds of industries thanks to our

customers, partners, and interested-parties.

As there is a saying, “Where there is a WILL, there is a WAY”, we have always been with great WILL to make everyone’s

life better and our valuable ones have not been reluctant to be our WAY.

The benefit as just our own is not the benefit, which makes everybody be successful.

We always believe that our related parties should be happy prior to our happiness for us to be happy eventually.

In the meantime, our products, Stainless and Nickel Alloy Wires and Welding Wires are meaningless as products themselves.

But, they are the core items connecting each industry in the world like connection between KOWEL and our every party.

We, KOWEL value the quality but not just high quality itself and we value quality stability more.

We, KOWEL value benefit, which comes to our customers first and comes to us as reflection later.

We, KOWEL are surely aware of that all customers deserve the right to purchase the quality products with best prices in the world and

we try our best to support their right.

We, KOWEL do not guarantee only low and cheap prices but reasonable ones, which make our quality stable and customers satisfied in long term.

We, KOWEL make sure that “somebody can feel our prices are higher than their expectation as not used our products before but every customer

who used ours says our price is not high but reasonable.”

Without our Admired Customers, Partners, and Interested-parties, we, KOWEL are nothing and we do not make them waiting."

-

- Business Type :

- Manufacturer

-

- Main Product :

- Steel Welding wire

-

- Established :

- 1982-01-01

-

- Total Annual Revenue :

- 9~10 billion (KRW)

-

- Total Employees :

- 51~100 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 9~10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 120

-

- Number of foreign trade employees

- 51~100 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- KOWEL Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

How to

Use

How to

Use