ITEM SPECIFICS

-

Brand

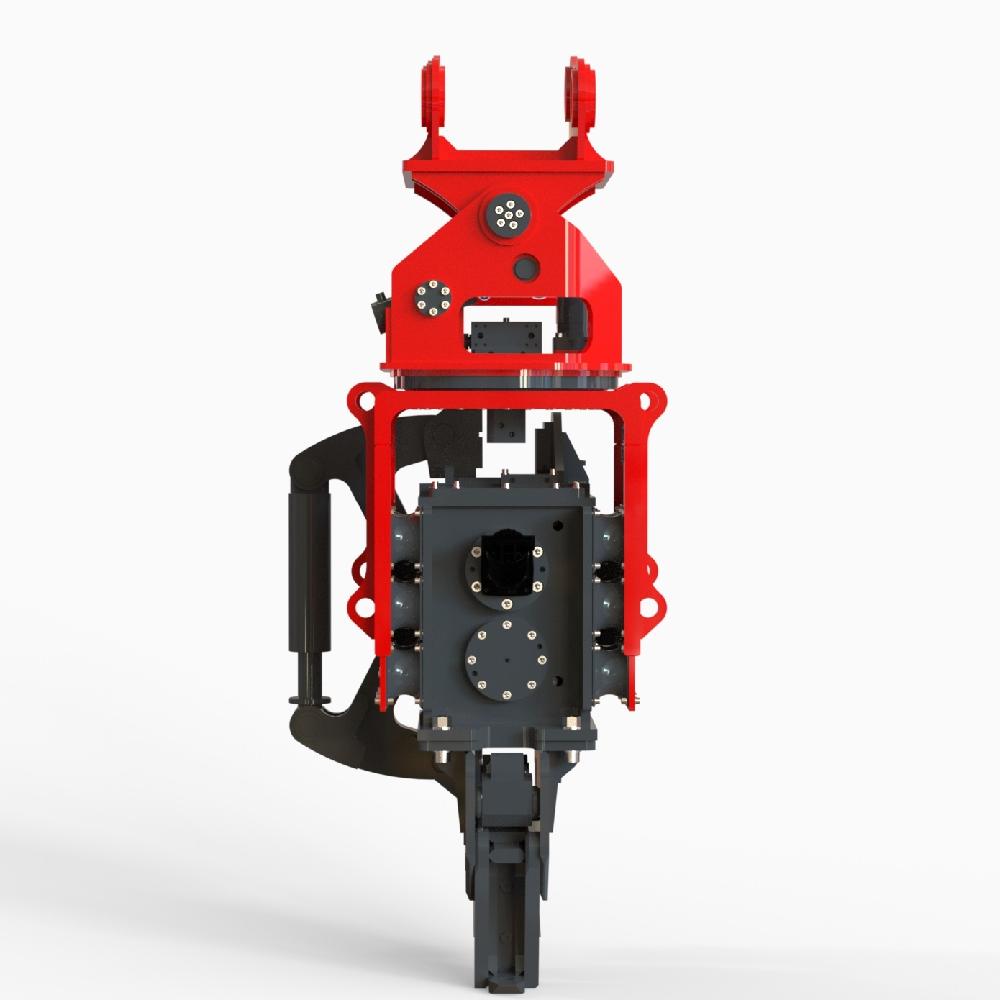

Model SG25, SG30STERLING TECHNOLOGY INC.

-

origin

Republic of Korea

-

Size(Capacity)

SG25: 1,165x1,189x2,600mm / SG30: 1,165x1,189x2,600mm

-

Weight

SG25: 2,100kg / SG30: 2,200kg

-

Function

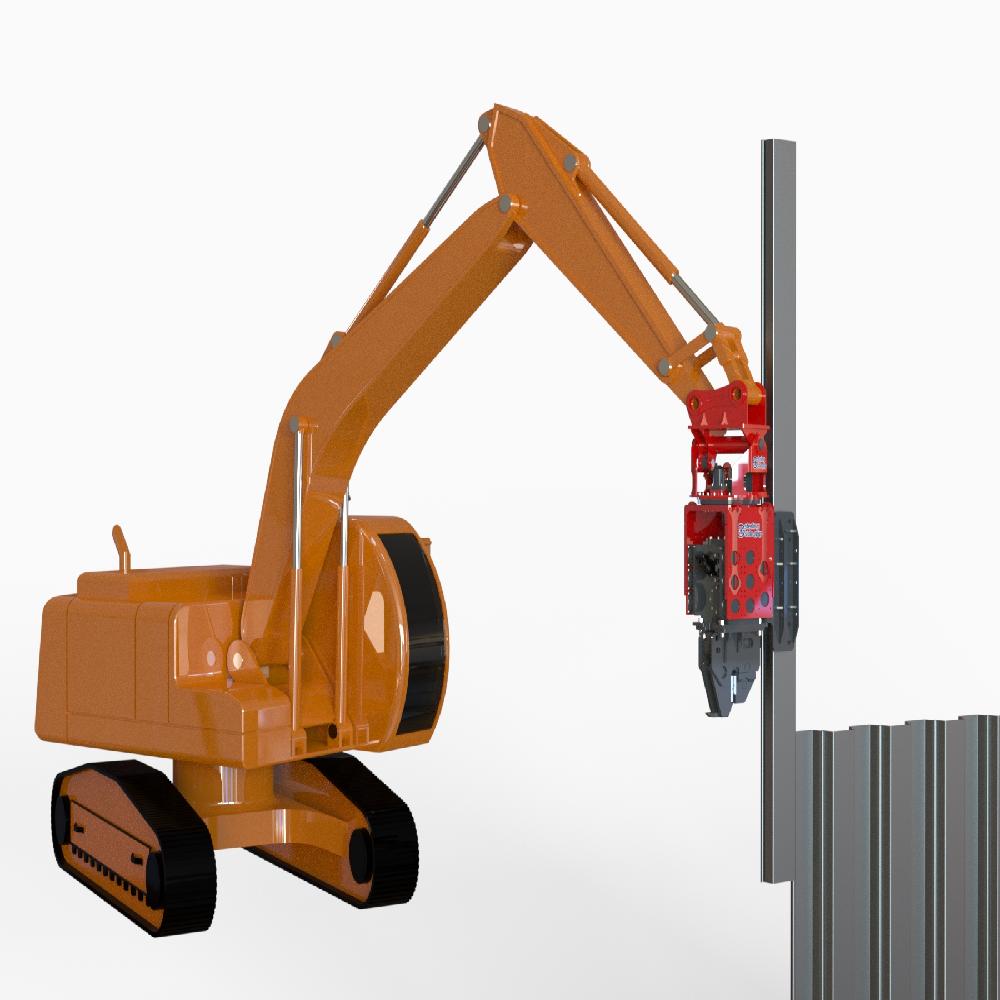

Side grip type excavator-mounted vibratory pile driver

-

Features

W-shape clamp structure of Sterling Side Grip allows precise and accurate side clamping

-

Color

red

PRODUCT DESCRIPTION

STERLING SIDE GRIP

Applications of Sterling Side Grip:

Significantly wider offerings and 4 market segments enable further success.

1. Sea Side

2. River Side

3. Head room construction

4. Confined space job site

Significantly wider offerings and 4 market segments enable further success.

1. Sea Side

2. River Side

3. Head room construction

4. Confined space job site

Features of Sterling Side Grip:

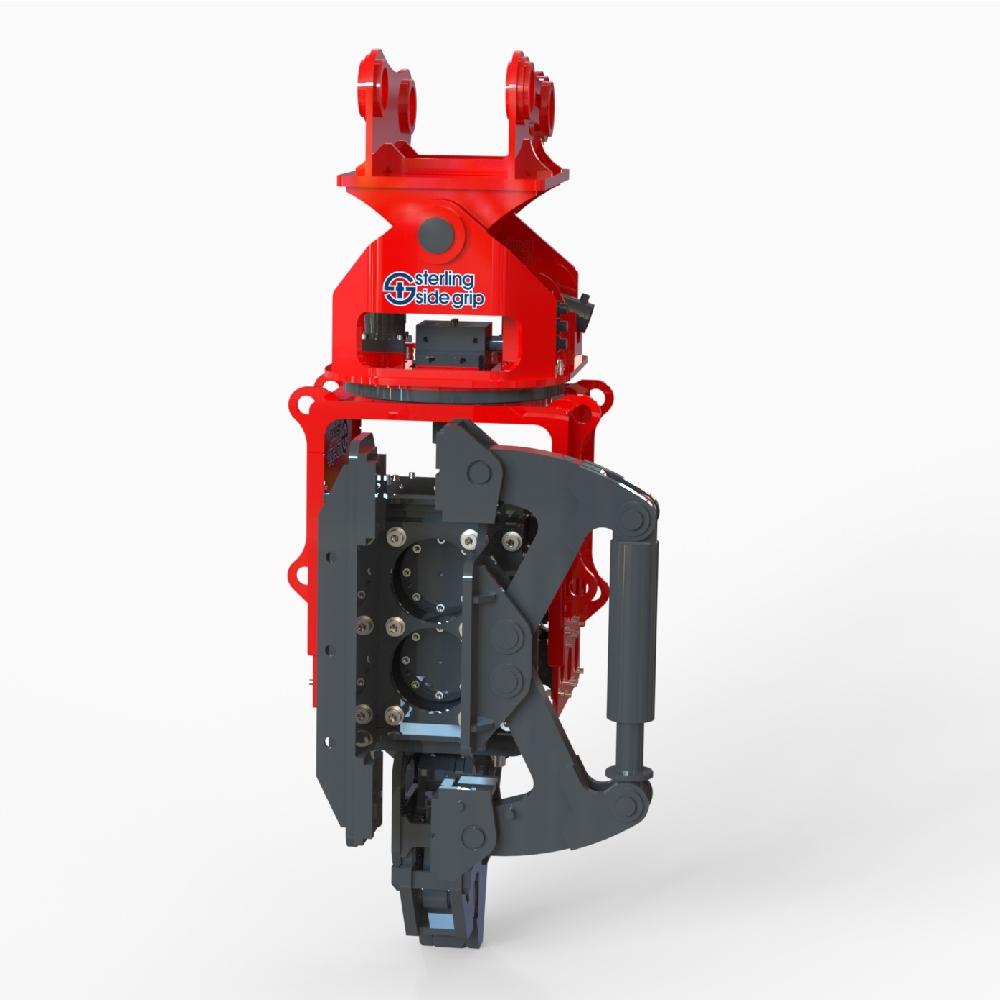

- available for wide ranges of piles (sheet piles, H beams, I-H beams, and round-piles)

- Versatile piling at a headroom job site

- versatile piling at a confined space job site

- precise and accurate side clamping (balanced four pads allows firmly, precisely and accurately clamping)

- quicker and more powerful (faster penetration and extraction than other side grip pile drivers thanks to bigger and double eccentric weight)

- low maintenance cost and easy maintenance (concise structure of components)

- rigid and durability (double bearings, balanced counter weighs and rigid rubber cushion

- available for wide ranges of piles (sheet piles, H beams, I-H beams, and round-piles)

- Versatile piling at a headroom job site

- versatile piling at a confined space job site

- precise and accurate side clamping (balanced four pads allows firmly, precisely and accurately clamping)

- quicker and more powerful (faster penetration and extraction than other side grip pile drivers thanks to bigger and double eccentric weight)

- low maintenance cost and easy maintenance (concise structure of components)

- rigid and durability (double bearings, balanced counter weighs and rigid rubber cushion

Conventional Pile Driver vs. Sterling Side Grip

Conventional side grip clamping unit has four clamping pads with two separate arm structure may cause inaccurate clamping. Frequent inaccurate clamping may lead to crack or damage of clamping cylinder and clamp arm. However, the Sterling side grip clamping unit is designed as a 'W-shape' clamp structure and balanced four pads that allow firmly, precisely and accurately clamping all the time.

Conventional side grip clamping unit has four clamping pads with two separate arm structure may cause inaccurate clamping. Frequent inaccurate clamping may lead to crack or damage of clamping cylinder and clamp arm. However, the Sterling side grip clamping unit is designed as a 'W-shape' clamp structure and balanced four pads that allow firmly, precisely and accurately clamping all the time.

Advantage of Sterling Side Grip:

*15% higher efficiency in its same class

- with the unique design of the double bearing structure, it allows at least 2 times longer lifetime of bearings. Also, the double bearing structure enables bigger eccentric weights to maximize vibratory power.

*15% higher efficiency in its same class

- with the unique design of the double bearing structure, it allows at least 2 times longer lifetime of bearings. Also, the double bearing structure enables bigger eccentric weights to maximize vibratory power.

Visit our website for more information : www.sterlingripper.com

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Binn Lim

SHIPPING

Shipping from :

Republic of Korea

- 26-58 Juseok-ro 80beon-gil Namyang-eup, Hwaseong-si, Gyeonggi-do (18255)

- Sea Freight : Please contact us for carriers inquiry

- Sea Freight : impossible

- Please contact your administrator for detailed information.

- Name : wooki,cheon

- Tel : 82-031-8055-8874

Sterling Technology Inc.

The person in charge

Binn LimAddress

26-58 Juseok-ro 80beon-gil Namyang-eup, Hwaseong-si, Gyeonggi-do (18255)

Introduction

Sterling Technology Inc. is a flexible company putting all its efforts to design and develop the innovative hydraulic attachment and vibratory pile drivers to meet customers’ requirements including also customers’ applications. With this strategy, Sterling Technology Inc. ensures effective piling, quarry, and mining work with high productivity for customers. With our hydraulic vibratory excavator attachment, you will get the best efficiency to your carrier machines. Our commitment is to offer the reliable quality products to our customers.

Product range

Side grip pile drivers

Vibratory hammers (Pile drivers)

Vibro rippers

Sterling Side grip pile driver

Advantages for Sterling Side grips are as follows.

• Available for wide ranges of piles : Sheet piles, H-beams and round piles

• Versatile piling at headroom jobsite

• Versatile piling at confined jobsite

Sterling rippers

Sterling rippers are one of the best solutions as an alternative or supplementary for primary breaking rocks for mines and construction sites as follows:

• Blasting banned partially/temporarily or permanently (This is the new trend at mines, quarries and construction sites all over the world.)

• Noise restricted area (This is the new trend at mines, quarries and construction sites all over the world.)

• Under water works

Sterling rippers can be solutions and/or problem solver where they are suffering from problems above and they would help to maximize productivity and minimize costs per hour at mine and construction sites.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Vibratory ripper, Pile driver,Vibratory ripper ,Vibratory hammer

-

- Established :

- 2018-06-12

-

- Total Annual Revenue :

- 1~2 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- CE

- TUV NORD CERT

- 2018.11.16

- 인증서보기

-

- ISO9001

- ACE

- 2018.11.2

- 인증서보기

-

- SO 9001

- ACE

- 2021.11.02

- 인증서보기

-

- CE(RIPPER)

- TUV NORD

- 2018.11.16

- 인증서보기

-

- CE(HAMMER)

- TUV NORD

- 2018.11.16

- 인증서보기

-

- TRCU(RIPPER)

- EAC

- 2019.05.28

- 인증서보기

-

- TRCU(HAMMER)

- EAC

- 2019.05.28

- 인증서보기

-

- TRCU(HYD.BREAKER)

- EAC

- 2020.02.26

- 인증서보기

-

- TRCU(AUGER CRANE)

- EAC

- 2020.02.26

- 인증서보기

-

- TRCU(SIDE GRIP)

- EAC

- 2020.02.26

- 인증서보기

-

- AUGER CRAIN HAMMER

- KIWA

- 2021.09.29

- 인증서보기

-

- SIDE GRIP PILE DRIVER

- KIWA

- 2021.09.29

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 1~2 billion (KRW)

-

- Total export revenue (previous year in USD)

- 800

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- Sterling Technology Inc. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★