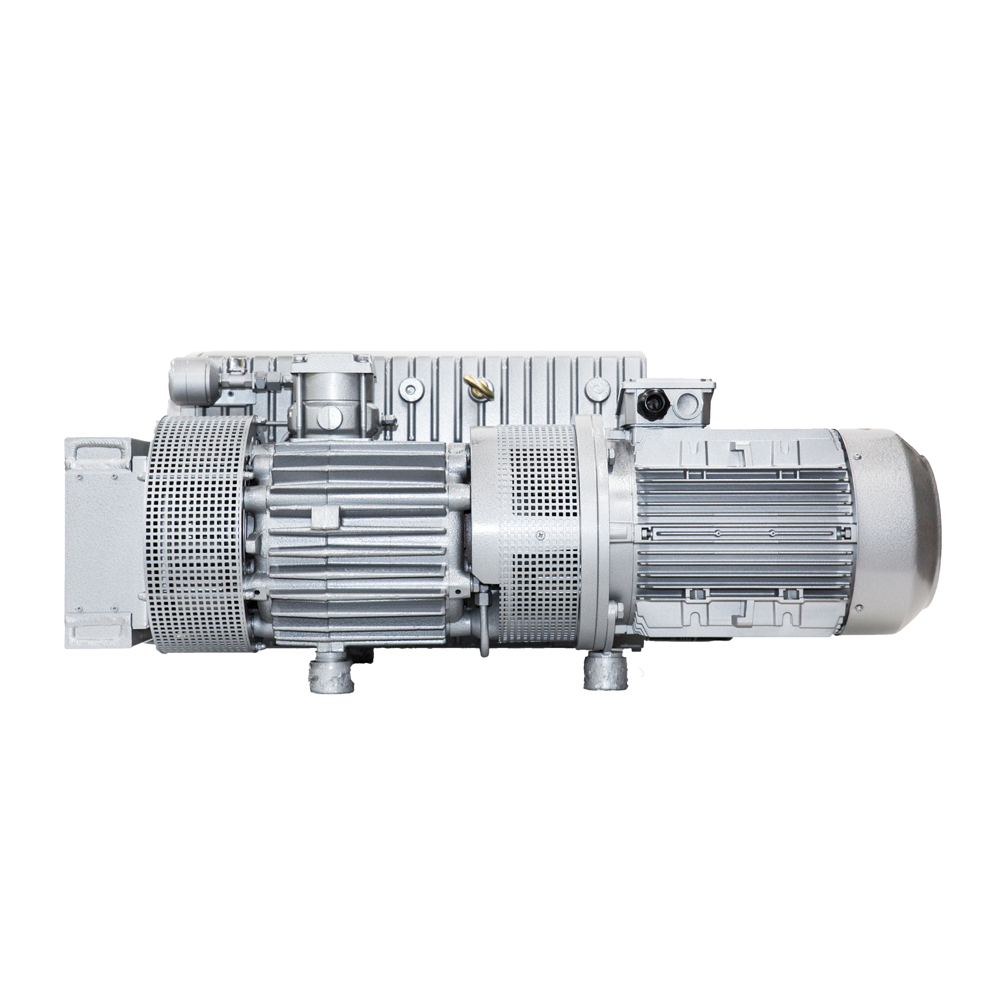

Rotary Vane Vacuum Pumps Oil Circulated

-

Payment

L/C(sight) , T/T

-

MOQ

1 Unit

-

Supply Ability

10,000 Unit per One-Time

-

Supply Details

Customization Sample Order

Negotiable / Depend on Quantity

-

Country of sale

Americas, Europe, World Wide, Asia, Middle East

-

PRICE

-

EXW

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model MVO 161/201/251/301dooVAC

-

origin

Republic of Korea

-

Size(Capacity)

Depending on the model

-

Function

Vacuum Pump

-

Color

Grey

-

Weight

218kg

-

Condition

New

PRODUCT DESCRIPTION

Rotary Vane Vacuum Pumps Oil Circulated

Description

This product is an oil circulating rotary vane vacuum pump and its basic structure is composed of rotor, vane and cylinder. The center of the rotor is eccentrically assembled to the center of the cylinder, and the three vanes rotated in a state of being closely attached to the inner wall of the cylinder by the centrifugal force. At this time, a space is created between the vane and the vane, creating vacuum throughout the four steps of suction, expansion, compression, and exhaust by changing the volume of the space.

The oil supply is constantly supplied by the differential pressure inside the cylinder, eliminating the need for a separate oil injection pump. The exhaust air containing oil is firstly discharged into the oil sump, and 99.9% of the oil is recovered when circulating through the oil dust filter installed at the upper part of the oil sump, and only the clean air is exhausted. The versatile application in various industries is one of its advantages such as food packing, vacuum packing, medical area, vacuum transporting, TV tube, laboratory, etc.

This product is an oil circulating rotary vane vacuum pump and its basic structure is composed of rotor, vane and cylinder. The center of the rotor is eccentrically assembled to the center of the cylinder, and the three vanes rotated in a state of being closely attached to the inner wall of the cylinder by the centrifugal force. At this time, a space is created between the vane and the vane, creating vacuum throughout the four steps of suction, expansion, compression, and exhaust by changing the volume of the space.

The oil supply is constantly supplied by the differential pressure inside the cylinder, eliminating the need for a separate oil injection pump. The exhaust air containing oil is firstly discharged into the oil sump, and 99.9% of the oil is recovered when circulating through the oil dust filter installed at the upper part of the oil sump, and only the clean air is exhausted. The versatile application in various industries is one of its advantages such as food packing, vacuum packing, medical area, vacuum transporting, TV tube, laboratory, etc.

Reliability

High quality material, quality control according to ISO 9001, CE,

mark authentication standard, automated machining facility, com puter control process, etc. Guarantee standardized and accurate

product manufacturing. Where operation of vacuum pump stops during vacuum work in direct coupling operation method of flange type. Check valve is installed at the suction hole in order to prevent reverse-flow.

High quality material, quality control according to ISO 9001, CE,

mark authentication standard, automated machining facility, com puter control process, etc. Guarantee standardized and accurate

product manufacturing. Where operation of vacuum pump stops during vacuum work in direct coupling operation method of flange type. Check valve is installed at the suction hole in order to prevent reverse-flow.

Environmentally safe

Air cooling, internal oil re-circulation, integral oil mist separator

for oil-free exhaust air, low vibration and low noise level allows this pump to be used in any environment.

Air cooling, internal oil re-circulation, integral oil mist separator

for oil-free exhaust air, low vibration and low noise level allows this pump to be used in any environment.

Easy to service

Compact design, air-cooling and easy access allows rapid and sim ple servicing with long periods between services. It is unnecessary

to do in the same way for replacing other consumables when oil change is needed. This pump is coupling direct type for used flange motor for international specification. Easy maintenance caused by reduced weight & electric consumption.

Compact design, air-cooling and easy access allows rapid and sim ple servicing with long periods between services. It is unnecessary

to do in the same way for replacing other consumables when oil change is needed. This pump is coupling direct type for used flange motor for international specification. Easy maintenance caused by reduced weight & electric consumption.

Miniaturization

This type of vacuum pump uses oil for lubrication of rotary part

and maintenance of vacuum may be obtained in order to be used for

various applications. Vacuum packing machine, food packing, labo ratory, medical instrument, vacuum molding, vacuum dryer, vacuum consolidate.

This type of vacuum pump uses oil for lubrication of rotary part

and maintenance of vacuum may be obtained in order to be used for

various applications. Vacuum packing machine, food packing, labo ratory, medical instrument, vacuum molding, vacuum dryer, vacuum consolidate.

Technical Specifications

| Technical Data | MVO 160 | MVO 200 | MVO 250 | MVO 300 | ||

| Norminal displacement | 50Hz 60Hz |

m3/h | 160 190 |

200 240 |

250 300 |

300 360 |

| Ultimate pressure | A | mbar | 0.5 | 0.5 | 0.5 | 0.5 |

| Motor version (3~) | 50Hz 60Hz |

V | 230/400 220/380 |

230/400 220/380 |

230/400 220/380 |

230/400 220/380 |

| Motor version (1~) | 50Hz 60Hz |

V | - | - | - | - |

| Norminal motor rating | 50Hz 60Hz |

kW | 5.5 5.5 |

5.5 5.5 |

7.5 7.5 |

7.5 8.6 |

| Norminal motor speed | 50Hz 60Hz |

min-1 | 1420 1700 |

1420 1700 |

1420 1700 |

1420 1700 |

| Sound level | 50Hz 60Hz |

dB(A) | 70 72 |

77 74 |

72 74 |

74 76 |

| Operating temperature(Abient) | °C | 40 | 40 | 40 | 40 | |

| Oil filling | liter | 7 | 7 | 7 | 7 | |

| Weight approx. | kg | 174 | 185 | 202 | 218 | |

Product Dimension

Performance Curve

Company Overview

dooVAC offers the most advanced vacuum pumps to which its own proprietary technologies have been applied. In the field of air solution, our vacuum pumps and compressors are recognized as having best performance and technologies, and we are establishing solid position as the leading company in the vacuum industries. dooVAC has been continuing innovations and devotions for customers, but not limited to Korean market. dooVAC has acquired ISO certification of vacuum pumps, compressors, parts and accessories in Europe, Asia, Canada and North & South America, then has been coping with the demands in those territories.

Other Products

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Telegraphic Transfer : T/T

- Name : Sang gil Won

SHIPPING

Shipping from :

Republic of Korea

- 30-30 Gobong-ro 770beon-gil Ilsandong-gu, Goyang-si, Gyeonggi-do (10251)

dooVAC Co., Ltd.

The person in charge

Seong-Kil HongAddress

30-30 Gobong-ro 770beon-gil Ilsandong-gu, Goyang-si, Gyeonggi-do (10251)

QR CODE

dooVAC Co., Ltd.

Introduction

dooVAC, founded in 1990, is a first generation of localizing vacuum pumps with 30 years experience and know-hows and is one of the promising small-medicum business in South Korea. There are more than 20 different products including oil circulation rotary vane vacuum pump, dry running rotary vane vacuum pump, etc. With manufacturing in-house technologies, dooVAC makes not only domestic markets, but also more than 20 oversea markets such as USA, Canada, India, Italy, Phillipines, and Argentina, etc, which considers it as a poweful small business. Products certified with ISO 9001, ISO 14001, CE, RoHs and foundation of firm’s in-house lab have impressed our customers with trusts and honests. Peaking $1 million revenues at 2019 recognizes dooVAC as an exporting promising company and in order to leap up to another level, it strives to develop the new product like a claw vacuum pump.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Vacuum transfer, MVO Series

-

- Established :

- 2013-09-05

-

- Total Annual Revenue :

- 1~2 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 1~2 billion (KRW)

-

- Total export revenue (previous year in USD)

- 922

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- dooVAC Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★