|

Introduction

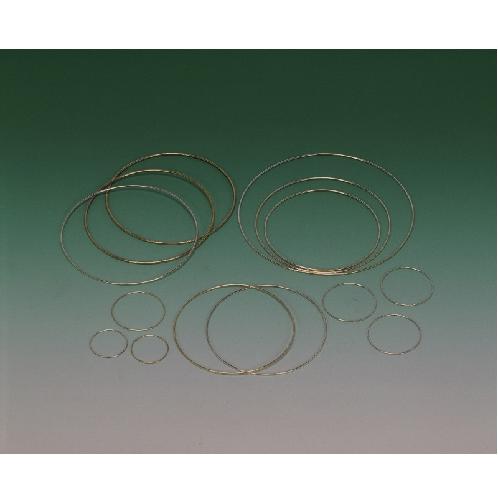

The metal O-Ring shape gasket made of stainless steel,inconel tube, or bent metal tube is welded and finished very precisely. For sealing of gases and volatile fluids, vacuum service,

PTFE coated type or silver plated type are recommended. two types are available as follows.

Main features / characteristics

Wide scope of use.

Stainless steel is used as the main material that it can be used at ultra-low temperature to a high temperature of 700℃

Wide scope of used pressure.

Can be used at ultra-high pressure of over 2,000 /㎠ and ultra-vacuum state.

Very little buoyancy compared to other metal gaskets and can be used in small spaces for Can be compactly designed.

Good chemical resistance.

Can be manufactured into special shapes other than wavy patterns.

METAL O-RING GASKET-Application

|

Pressure and direction pressure

|

Service requirement

|

Type of flange

|

View

|

|

Lower than 5kgf/cm2 or vacuum

|

In case that an easy exchange of gasket is requored and grooving of flange surface is undersirable

|

①

|

|

|

Both internal and external pressure

|

The process lines where a sudden change of pressure and repeated pressure cycles are expected

|

②

|

|

The process lines that handle highly viscous fliid or corrosive fluid, or fluid that contains slurries

|

③

|

|

Male and female flange

|

④

|

|

Higher than 5kgf/cm2 external pressure

|

Male and female flange

|

⑤

|

|

Flat face flange or tongue and groove flange

|

⑥

|

METAL O-RING GASKET-Form

|

|

SSI 850

|

SSI 851

|

|

Type

|

Basic Type

|

Balanced Type |

|

Section

|

|

|

| Description |

Basic type Metal O-Ring made of metal tube, which is formed and buttwelded into various shapes. The metal O-ring attaches to the flange groove to exert a crushing force and seal the fluid with repulsive force. It is suitable for medium pressure service ranging from 10-12torr vacuum to 70kg/cm2[6.8MPa]. It is necessary to use with a retainer ring when used on raised or flat face flange. |

Balanced type Metal O-Ring made of metal tube which is formed and buttwelded into various shapes having be holes at the inside against internal presure or at the outside external pressure. A hole is made in the fluid side of the O-ring to introduce fluid pressure into the hollow part. Then the sealing force is increased. It is mainly used for higher presser exceeding 70kg/cm2, our experimental experience shows that it withstands 6000atu hydraulic pressure.

|

Material Service

| Used |

Material Service

|

Temperature resistance(℃)

|

|

Tube

|

SUS 304

SUS 321

Inconel X-750

Incoloy 800

|

-250~540

-250~870

-250~1090

-250~980

|

|

Surface treatment

|

P.T.F.E coating

Siliver plating

Nickel plating

Copper plating

|

-200~260

-250~650

-250~760

-250~700

|

|

PLATINUM

PLATINUM