ITEM SPECIFICS

-

Brand

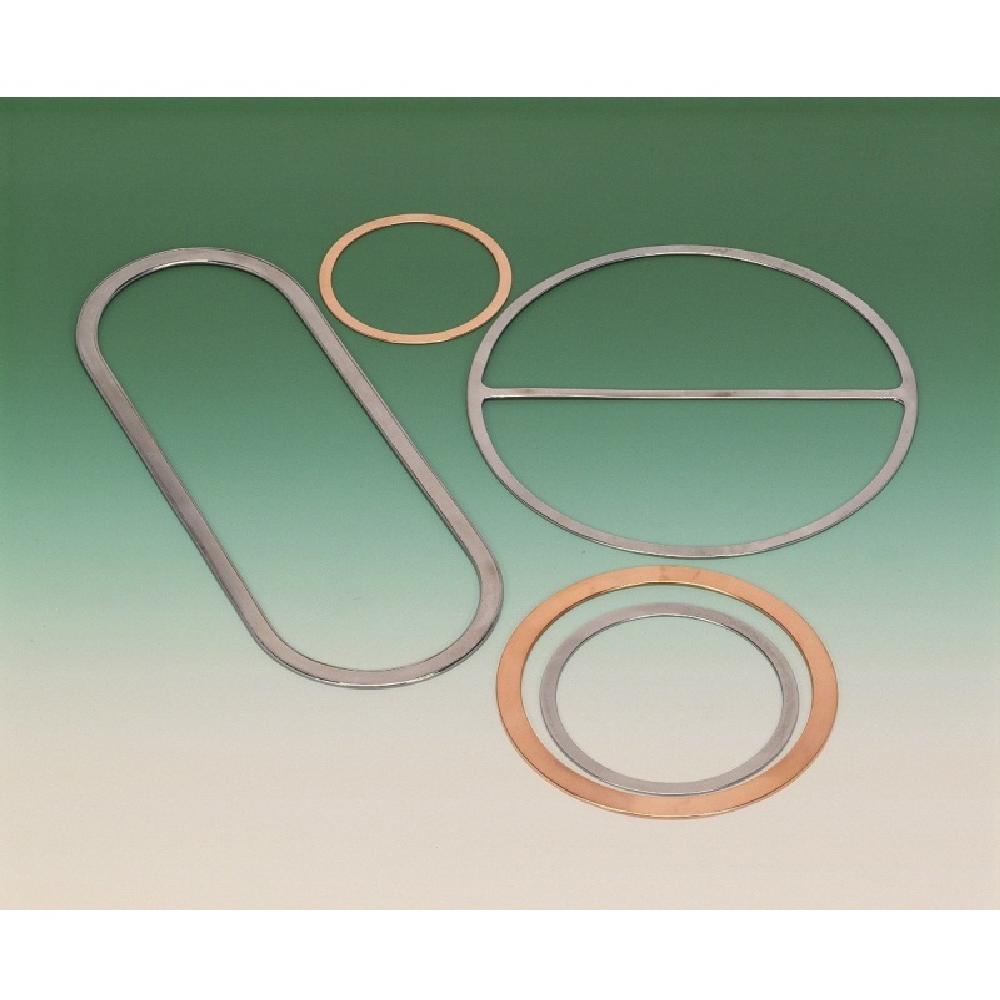

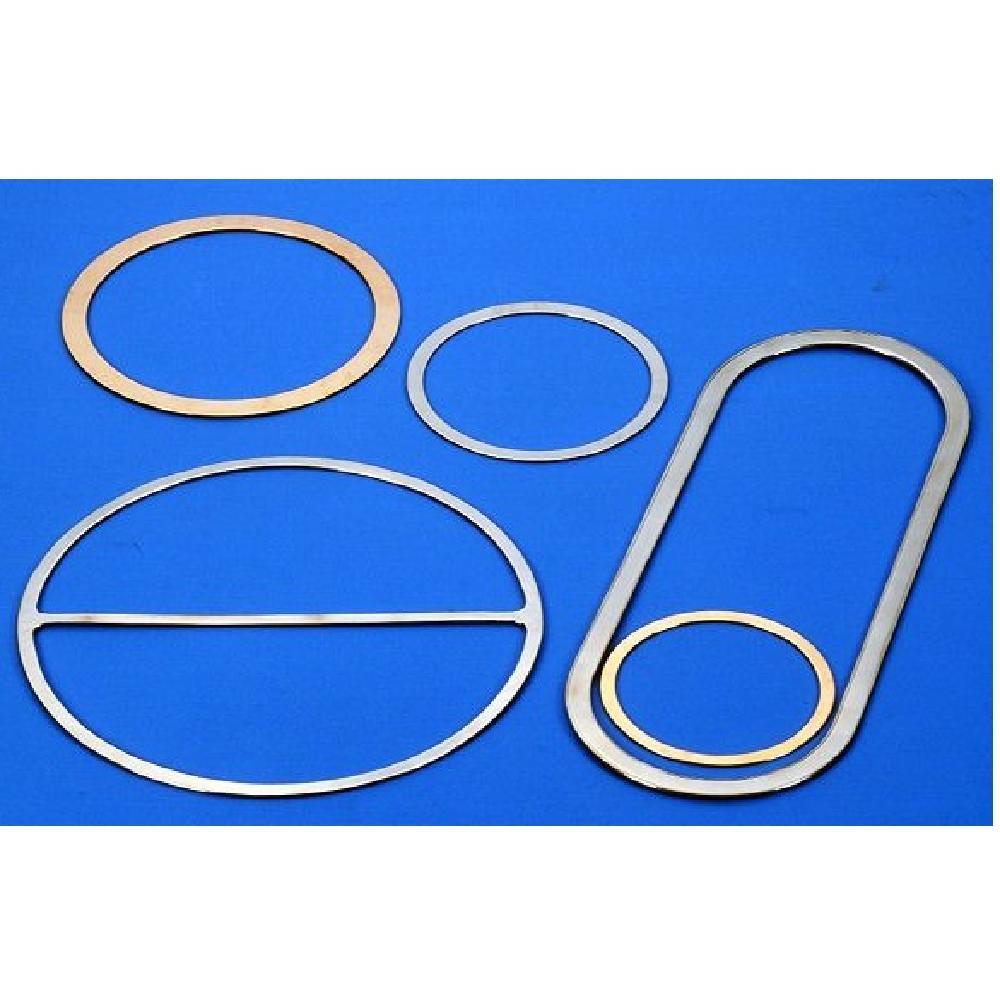

Model SSI #840, 841, 842, 843, 844, 840GP, 842GP, 845, 846, 847Unbranded

-

origin

Republic of Korea

-

Size(Capacity)

PRODUCT DESCRIPTION

|

Introduction

|

R&D CERTIFICATE

PAYMENTS DETAILS

- Telegraphic Transfer : T/T

- Name : LIM, CHEOL-JIN

SHIPPING

- 264-3, HAKJANG-DONG, SASANG-GU, BUSAN, KOREA, 부산광역시,

The person in charge

Address

264-3, HAKJANG-DONG, SASANG-GU, BUSAN, KOREA, 부산광역시,

-

- Business Type :

- Manufacturer

-

- Main Product :

-

- Established :

- 1985-01-01

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- SAMSUNG INDUSTRY CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★