LNG Bunkering Station (Skid) & & liquefaction system

-

Payment

L/C(sight) , L/C(usance) , T/T

-

MOQ

1 Set

-

Supply Ability

1,000 Set per One-Time

-

Supply Details

Customization Limited goods

Request details on inquiry

-

Country of sale

Asia, Americas, Europe, Middle East, Africa

-

PRICE

-

EXW

Depend on quantity

-

FOB

Depend on quantity

-

DAP

Depend on quantity

-

CIF

Depend on quantity

-

CPT

Depend on quantity

-

CFR

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model LNG BSValmax

-

origin

Republic of Korea

-

Size(Capacity)

Customized

-

Package Includes

Valve, Flow Meter, Piping etc.

-

Function

Supplies LNG to Fuel Storage Tank of engines and generators for LNG fuel lines

-

Material

Customized

-

Color

Customized

-

Dimensions

Customized

PRODUCT DESCRIPTION

LNG Bunkering Station (Skid)

It is a facility that supplies LNG to Fuel Storage Tank of engines and generators for LNG fuel lines.

The system includes the bunkering skid emergency disconnection and shutdown fire prevention restraint quick coupler, ESD valve and fire protection.

Preparation for safety accidents caused by LNG bunkering is reflected in the design (IGF code).

Valmax is currently working on a system design and localization process in South Korea and is currently developing a test SKID by linking it to a national project. (Differential treatment is under development with small and large MODEL based on 500TON class.)LNG Regasification System

Installed on the LNG FSRU/LNG RECEIVING TREMMINAL/LNG FGSS.

It consists of LNG PUMP SKID/LNG VAPORIZER SKID & HEAT EXCHANGER SKID.

The LNG VAPORIZER TYPE is largely made up of two parts.

1. SHELL & TUBE type used for Low & High pressure

2. PCHE (DCHE) type used for High pressure (OVER 100 Bara)

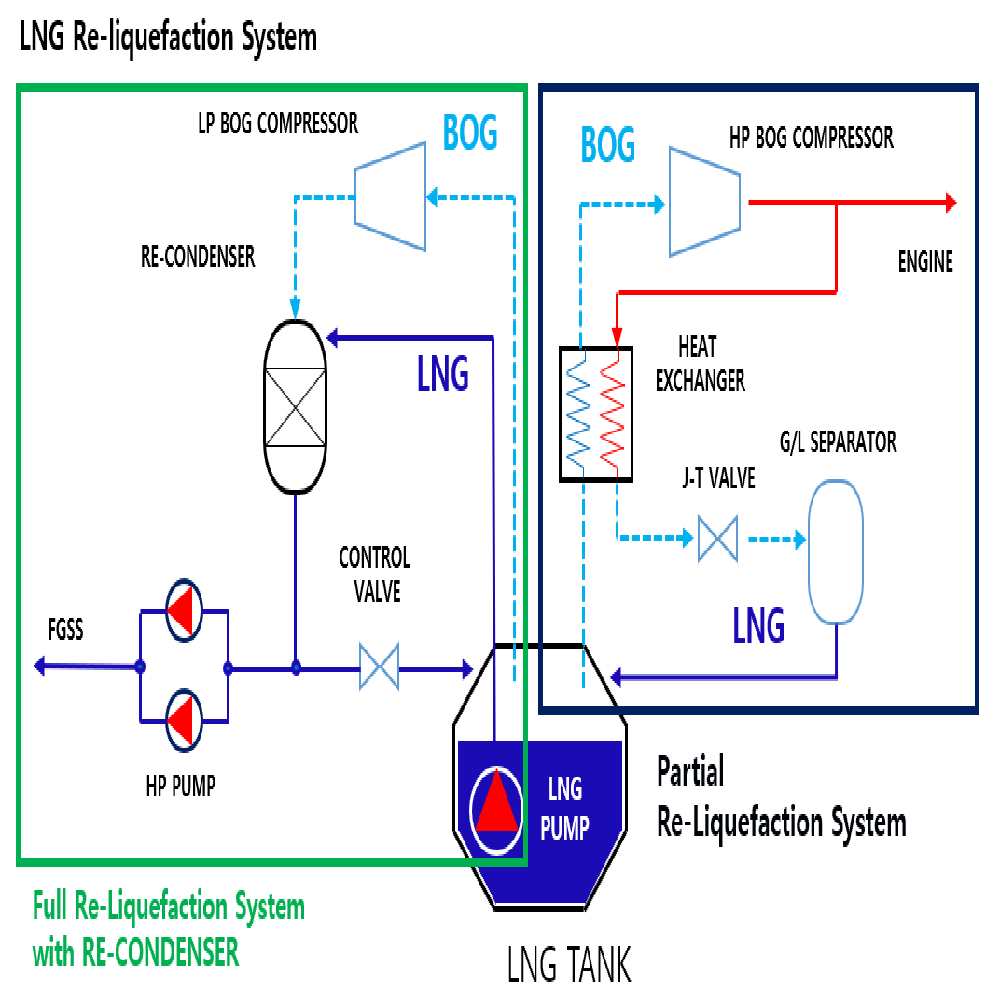

The HEAT MEDIA of LNG VAPORIZER has improved corrosion problems caused by using the direct heating method mainly using GLYCOL WATER.BOG Handling & liquefaction system

This system ensures the effective utilization of the BOG generated by the LNG Storage Tank.

Compress and condensing the BOG to liquefy it into LNG or to compress the BOG using the BOG Re-condenser and mix it with LNG

The system described above is applicable to the overall process design of LNGC or large LNG fueled ships (such as bulk ships) and is an efficient LNG FGSS.

Valmax has core technologies and produces and supplies BOG Re-Liquefaction System design related to these technologies.R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Letter of Credit : L/C(usance)

- Telegraphic Transfer : T/T

- Name : Sales Department

SHIPPING

Shipping from :

Republic of Korea

- 10 Asanbaelli-ro 387beon-gil Dunpo-myeon, Asan-si, Chungcheongnam-do (31408)

Valmax Technology Corporation

The person in charge

Il-Hwan KimAddress

10 Asanbaelli-ro 387beon-gil Dunpo-myeon, Asan-si, Chungcheongnam-do (31408)

Introduction

Valmax was founded in 2002 by a group of engineers with extensive experience in the development of custody transfer metering and process control systems for natural gas, industrial gases and oil products.

With over 10years experience, Valmax is a leading manufacturer specialized in Custody Metering System, Analyzer System Package, Fuel Gas Supply System, Re-condenser, LNG Regasification System, LNG Bunkering System, LNG Mobile filling station and LNG satellite station. We have confidently played a role as a reliable supplier to major EPC companies for different kinds of projects around the world. We can provide the total solution for Engineering, Procurement, Fabrication and After Sales Service.

Our solutions are based on the needs of our customers. By understanding the issues involved in the design you have in mind for your system, we’re able to deliver solutions that really hit the target.

-

- Business Type :

- Manufacturer

-

- Main Product :

- LNG Reliquefaction Regasification, LNG Mobile Filing Station Satellite Station, Fuel Gas Supply System, Metering analyzer System, CEMS

-

- Established :

R&D CERTIFICATE

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- Valmax Technology Corporation Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★