ITEM SPECIFICS

-

Brand

Model ST/STS/SPUnbranded

-

origin

Republic of Korea

-

Size(Capacity)

PRODUCT DESCRIPTION

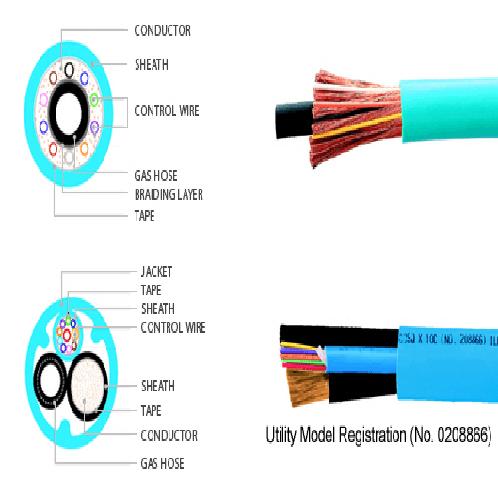

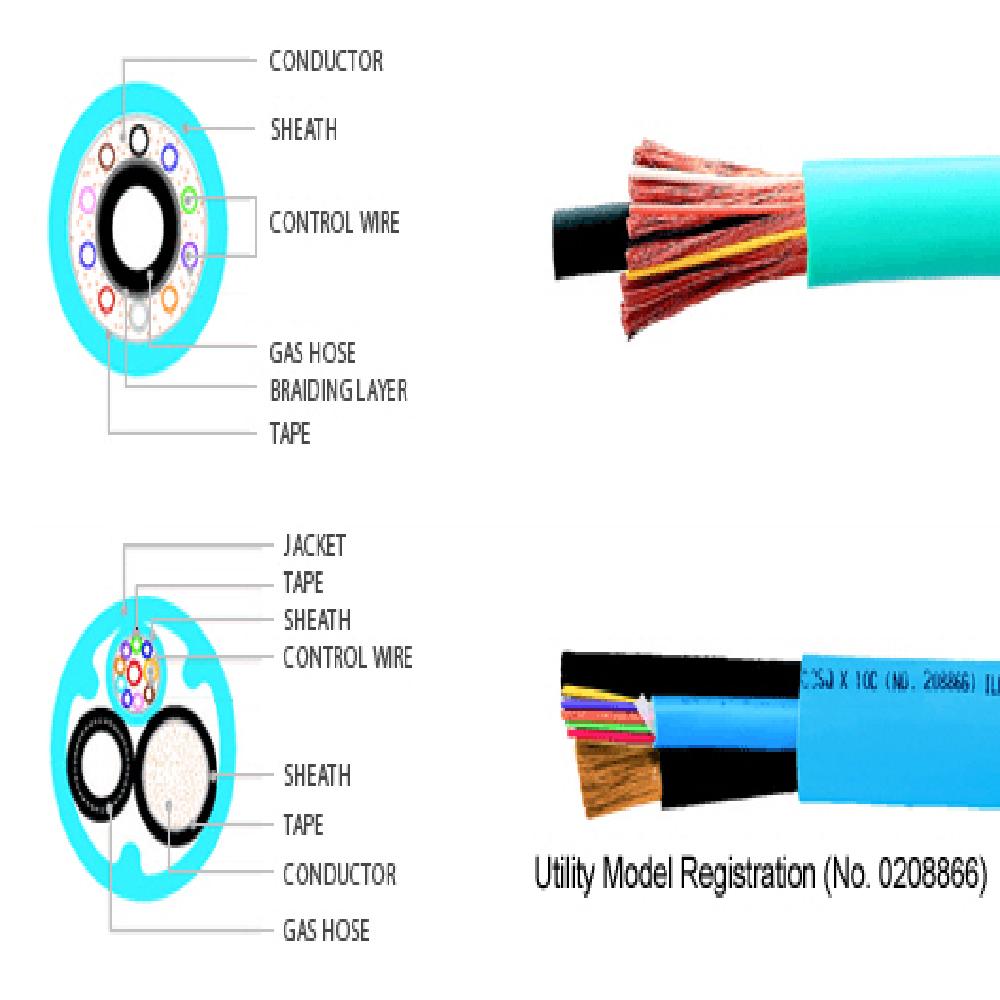

Introduction

CO2 Welding Single Cable can be very usefully applied for all types of work places requiring

extension of length between power source and wire feeder such as shipbuilding, construction,

steel x-frame, large sized industrial machinery fabrication, etc.

Features

-Remarkable light weight - It can be easily installed and dismantled and also cable transport.

-It allows smooth gas flow under non-straight status in 50M, without any drop of current or voltage.

-Its ideal structure design prevents fault rate of the welding equipment due to cable failure and

simplified parts allow anyone to repair or assemble/disassemble.

-As it has excellent gas hose and external jacket properties (heat resistance, tensile resistance,

aging resistance, etc.), it cannot be easily damaged by external impact.

Spec

- [STS] TYPE

|

Nominal |

Construction |

||||||||

|

Conductor |

Gas

Hose

ness |

Stran

ding

meter |

Tape

ness |

Sheath

ness |

Approx.

meter |

||||

|

No.&

meter |

Control wire |

||||||||

|

Thick

ness |

Dia

meter |

||||||||

|

㎟ |

No/mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

|

38 |

38 |

10/72/0.26 |

- |

- |

2.75 |

17.7 |

0.15 |

2.5 |

23.0 |

|

1.25 |

65/0.16 |

0.46 |

2.41 |

||||||

|

0.75 |

41/0.16 |

0.46 |

2.10 |

||||||

|

Gas |

8.0(I.D) x S x 13.5(O.D) |

||||||||

|

50 |

50 |

13/72/0.26 |

- |

- |

2.75 |

18.2 |

0.15 |

2.5 |

23.5 |

|

1.25 |

65/0.16 |

0.46 |

2.41 |

||||||

|

0.75 |

41/0.16 |

0.46 |

2.10 |

||||||

|

Gas |

8.0(I.D) x S x 13.5(O.D) |

||||||||

|

60 |

60 |

12/94/0.26 |

- |

- |

2.75 |

18.7 |

0.15 |

3.0 |

25.0 |

|

1.25 |

65/0.16 |

0.46 |

2.41 |

||||||

|

0.75 |

41/0.16 |

0.46 |

2.10 |

||||||

|

Gas |

8.0(I.D) x S x 13.5(O.D) |

||||||||

|

80 |

80 |

16/94/0.26 |

- |

- |

2.75 |

19.7 |

0.15 |

3.0 |

26.0 |

|

1.25 |

65/0.16 |

0.46 |

2.41 |

||||||

|

0.75 |

41/0.16 |

0.46 |

2.10 |

||||||

|

Gas |

8.0(I.D) x S x 13.5(O.D) |

||||||||

- [SP] TYPE

|

Nominal |

Construction |

|||||||||||

|

Conductor |

Tape

ness |

Gas

Hose

ness |

Sheath

ness |

meter |

Jacket

ness |

Approx.

Overall

meter |

||||||

|

No.& |

Dia

meter |

Control wire |

||||||||||

|

Thick

ness |

Dia

meter |

|||||||||||

|

㎟ |

No/mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

||

|

38 |

38 |

24/30/0.26 |

9.0 |

- |

- |

0.15 |

- |

1.9 |

12.8 |

2.0 |

29.0 |

|

|

1.25 |

65/0.16 |

- |

0.46 |

2.41 |

0.15 |

- |

1.25 |

11.0 |

||||

|

0.75 |

40/0.16 |

- |

0.46 |

2.10 |

||||||||

|

Gas |

6.5(I.D) x S x 12.0(O.D) |

2.75 |

- |

12.0 |

||||||||

|

50 |

50 |

16/59/0.26 |

9.7 |

- |

- |

0.15 |

- |

2.0 |

14.0 |

2.0 |

30.0 |

|

|

1.25 |

65/0.16 |

- |

0.46 |

2.41 |

0.15 |

- |

1.25 |

11.0 |

||||

|

0.75 |

40/0.16 |

- |

0.46 |

2.10 |

||||||||

|

Gas |

6.5(I.D) x S x 12.0(O.D) |

2.75 |

- |

12.0 |

||||||||

|

60 |

60 |

12/94/0.26 |

10.2 |

- |

- |

0.15 |

- |

2.0 |

14.5 |

2.0 |

31.0 |

|

|

1.25 |

65/0.16 |

- |

0.46 |

2.41 |

0.15 |

- |

1.25 |

11.0 |

||||

|

0.75 |

40/0.16 |

- |

0.46 |

2.10 |

||||||||

|

Gas |

6.5(I.D) x S x 12.0(O.D) |

2.75 |

- |

12.0 |

||||||||

|

80 |

80 |

16/94/0.26 |

12.7 |

- |

- |

0.15 |

- |

1.5 |

16.0 |

2.0 |

32.0 |

|

|

1.25 |

65/0.16 |

- |

0.46 |

2.41 |

0.15 |

- |

1.25 |

11.0 |

||||

|

0.75 |

40/0.16 |

- |

0.46 |

2.10 |

||||||||

|

Gas |

6.5(I.D) x S x 12.0(O.D) |

2.75 |

- |

12.0 |

||||||||

Etc

The construction of conductor, the number of control wire, and gas hose size can be customized

for customer’s requirement

PAYMENTS DETAILS

- Telegraphic Transfer : T/T

- Name : Hye min Kang

SHIPPING

- 206 Noksansaneopbuk-ro, Gangseo-gu, Busan (46753)

The person in charge

Ji hyun LeeAddress

206 Noksansaneopbuk-ro, Gangseo-gu, Busan (46753)

QRCODE

-

- Business Type :

- Manufacturer

-

- Main Product :

- Welding cable

-

- Established :

- 1989-01-01

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 11~50 people

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 381

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- ILHUNG CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★