ATS Air Mount

-

Payment

L/C(sight) , OT , T/T

-

MOQ

1 ea

-

Supply Ability

100 ea per One-Time

-

Supply Details

Customization Sample Order

Depends on quantity / If you want to buy in bulk, please contact me.

-

Country of sale

Europe, Americas, Asia, Middle East, World Wide

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model ATAM-SeriesATS

-

origin

Republic of Korea

-

Size(Capacity)

Weight (0.5~35kgf)

-

Material

Rubber

-

Weight

It is different by model (Weight (0.5~35kgf))

-

Function

Isolator (for anti vibration)

-

Features

Excellent anti-vibration efficiency against shock, vibration and structure borne vibration.

-

Gender

None

-

age-appropriate

None

PRODUCT DESCRIPTION

ATS Air Mount

[Product Features]

• Excellent anti-vibration efficiency against shock, vibration, and structure borne vibration

• With vertical natural frequency as 2.5~9.5Hz, minimized horizontal direction deformation

• No need of airline as to air injection type (2-6kgf/ ㎠) Isolator.

• Equipment stability is ensured by laterally reinforced steel, excellently durable elastomer(NR), stopper, and non-slip pad that doesn't require anchor for floor fixation

• Model No. : ATAM-50, ATAM-100, ATAM-150, ATAM-200, ATAM-300, ATAM-430

• With vertical natural frequency as 2.5~9.5Hz, minimized horizontal direction deformation

• No need of airline as to air injection type (2-6kgf/ ㎠) Isolator.

• Equipment stability is ensured by laterally reinforced steel, excellently durable elastomer(NR), stopper, and non-slip pad that doesn't require anchor for floor fixation

• Model No. : ATAM-50, ATAM-100, ATAM-150, ATAM-200, ATAM-300, ATAM-430

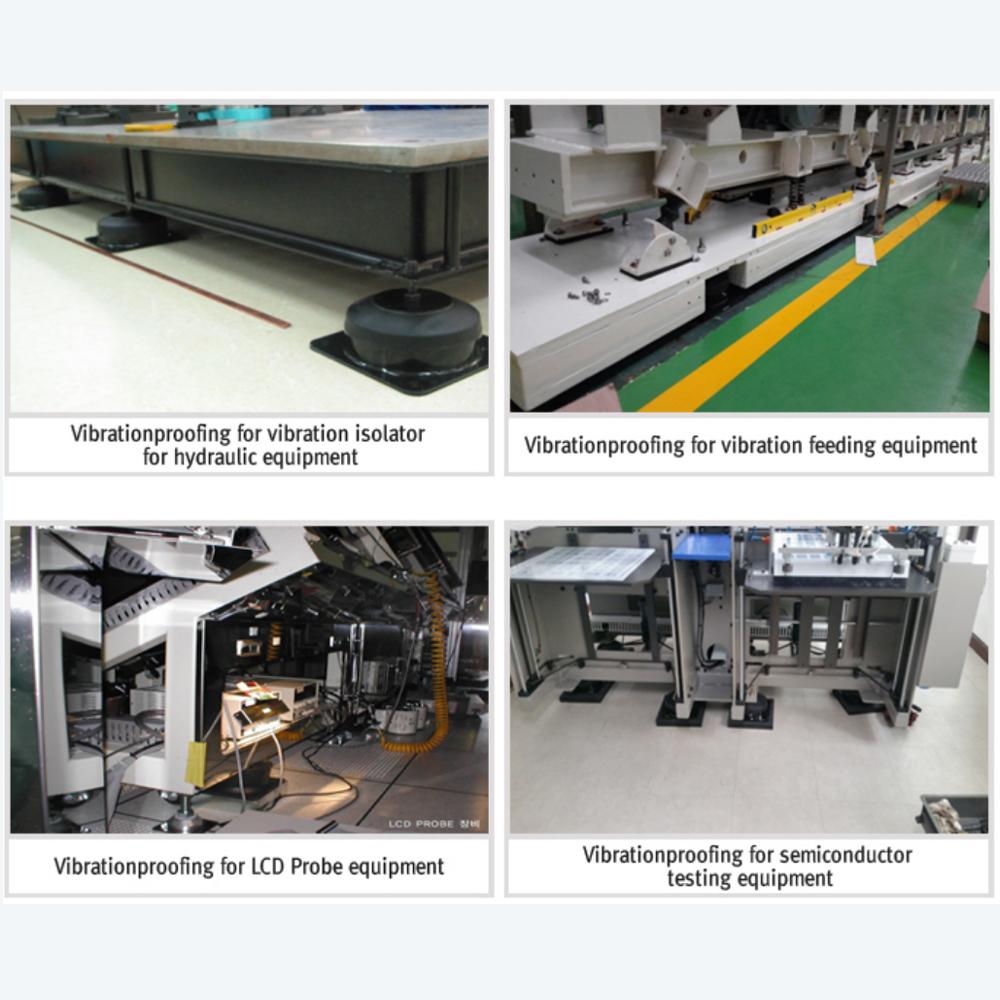

[Product Use]

• Dynamic load equipment for large machines (stamping press, forging hammer etc.)

• Precision measurement, optical, and testing equipment

• Semiconductor and LCD manufacturing equipment (Assembly, FAB)

• Rotating machines (turbine, air compressor etc), air-conditioner and isolation inertial mass

• Anti-vibration equipment for apartment-style factories ( sealing machine, printing machine etc.)

• Precision measurement, optical, and testing equipment

• Semiconductor and LCD manufacturing equipment (Assembly, FAB)

• Rotating machines (turbine, air compressor etc), air-conditioner and isolation inertial mass

• Anti-vibration equipment for apartment-style factories ( sealing machine, printing machine etc.)

[Product Specifications]

| Model | Load (kgf) | Pressure (kgf/cm²) |

Displacement (mm) |

Natural Frequency (Hz) |

Dimension (mm) | Weight (kgf) |

||||||

| L1 | L2 | D1 | D2 | H | M | PT | ||||||

| ATAM-50 | 10~40 | 3 | ±3 | 6.3~9.2 | 100 | 80 | Ø80 | Ø36 | 63 | M10 (12DP) |

Ø10 | 0.5 |

| ATAM-100 | 50~250 | 3 | ±3 | 6.0~7.0 | 140 | 110 | Ø114 | Ø56 | 65 | M12 (20DP) |

Ø12 | 0.5 |

| ATAM-150 | 100~550 | 3 | ±5 | 5.0~6.0 | 200 | 160 | Ø165 | Ø82 | 95 | M16 (24DP) |

Ø10 | 0.5 |

| ATAM-200 | 250~1100 | 3 | ±5 | 4.0~5.0 | 250 | 200 | Ø216 | Ø120 | 95 | M16 (24DP) |

Ø10 | 0.5 |

| ATAM-300 | 1000~3000 | 3 | ±5 | 2.5~3.7 | 390 | 330 | Ø356 | Ø204 | 95 | M20 (30DP) |

Ø10 | 0.5 |

| ATAM-400 | 2000~6500 | 3 | ±7 | 2.3~3.5 | 500 | 420 | Ø480 | Ø320 | 95 | M20 (30DP) |

Ø10 | 0.5 |

[Load and displacement test]

[Precautions for installation]

• Operating temperature : -10℃ to 80℃

• The product should be protected with a cover if any of high-temperature metal, oil, acids etc. are used.

• The product shall be kept in dark, dry locations at room temperature

• An adequate amount of air may be injected only after the product has been installed on equipment. Injecting air before its installation may damage the product.

• The user is required to consult our technicians as the installation must take into account allowed displacement, lateral stability, the position of center of gravity, resonance during equipment operate and stop.

• The product should be protected with a cover if any of high-temperature metal, oil, acids etc. are used.

• The product shall be kept in dark, dry locations at room temperature

• An adequate amount of air may be injected only after the product has been installed on equipment. Injecting air before its installation may damage the product.

• The user is required to consult our technicians as the installation must take into account allowed displacement, lateral stability, the position of center of gravity, resonance during equipment operate and stop.

Other Products

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- OT

- Telegraphic Transfer : T/T

- Name : So Gwon Kim

SHIPPING

Shipping from :

Republic of Korea

- 28 Mayu-ro 32beon-gil, Siheung-si, Gyeonggi-do (15116)

ATS Co., Ltd.

The person in charge

Seok-won KimAddress

28 Mayu-ro 32beon-gil, Siheung-si, Gyeonggi-do (15116)

ATS

ATS Co., Ltd.

Introduction

Envisioning a global maker of advanced and innovative anti-vibration and automation parts, ATS works toward the best value to turn the company's goals into global trends.

The company engages in all kinds of works of operations in designing, Analyzing, developing, testing, manufacturing, and selling ant-vibration products including Air Spring, Isolation Mount, Isolation Pad and automation parts including Air Picker, Inflatable Seal, Expansion Bladder, Lifting Bag. ATS is a company that provides solutions of advanced technology through hospitable customer support services with its excellent design from raw materials and world-class engineering.

[Our Service]

- 1) Product manufacturing

- 2) Product development

- 3) Noise&Vibration measurement and analysis

-

- Business Type :

- Manufacturer

-

- Main Product :

- Air Spring, Inflatable Seal

-

- Established :

- 2013-07-09

-

- Total Annual Revenue :

- 3~4 billion (KRW)

-

- Total Employees :

- 11~50 people

R&D CERTIFICATE

-

- ISO 9001:2015

- ICR_INTERNATIONAL CERTIFICATION REGISTRAR

- 2018.10.26

- 인증서보기

-

- ISO 14001:2015

- ICR_INTERNATIONAL CERTIFICATION REGISTRAR

- 2018.10.26

- 인증서보기

-

- ISO 9001:2015

- ICR

- 2018.10.26

- 인증서보기

-

- ISO 14001:2015

- ICR

- 2018.10.26

- 인증서보기

-

- Certificate of patent_NO.10-1787658

- Commissioner, Korean intellectual property office

- 2017.10.12

- 인증서보기

-

- Certificate of patent_NO.10-2386269

- Commissioner, Korean intellectual property office

- 2022.04.08

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~4 billion (KRW)

-

- Total export revenue (previous year in USD)

- 29

-

- Number of foreign trade employees

- 11~50 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- ATS Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★