AI inline appearance inspection

-

Payment

T/T

-

MOQ

Negotiable

-

Supply Details

Customization

Negotiable

-

Country of sale

Asia, Americas, Europe, Africa, World Wide

-

PRICE

-

FOB

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model LAON PEOPLELAON PEOPLE

-

origin

Republic of Korea

-

Size(Capacity)

Customization

-

Dimensions

Customization

-

Style

conveyor belt

-

Function

AI inline appearance inspection

PRODUCT DESCRIPTION

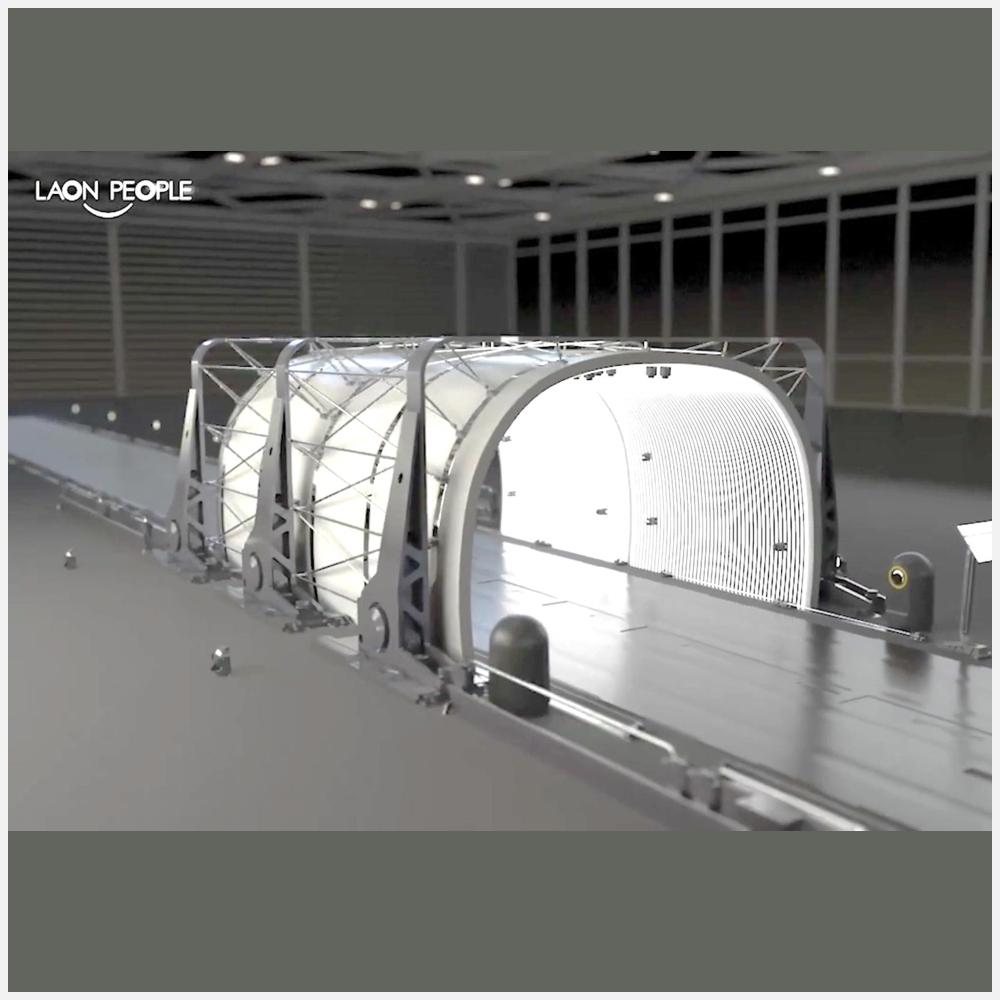

The AI inline finished car visual inspector is a machine for the visual inspection that investigates and photographs the lighting while the product is moving from the conveyor belt. This product enables faster and more accurate inspection compared to visual inspection with pattern optics and self-developed AI deep learning technology. By combining pattern lighting and AI deep learning technology, it can secure high detection power for a wide range of defects such as bad chip/painting condition, dent, scratch, foreign material, bubble, paint clumping/contamination, and dust on the surface of glossy products including automobiles, and significantly lower caustic defects.

The basic concept of the finished vehicle visual inspector proceeds in three stages: vehicle entry, pattern lighting investigation and inspection, and vehicle exit. In the vehicle entry stage, a trigger occurs when the vehicle enters, and when vehicle information is delivered to the system after vehicle recognition, the system prepares an inspection system according to the vehicle type inspection recipe. In the vehicle inspection stage, defects present on the vehicle painting surface are inspected. In the vehicle exit stage, triggers occur when leaving the vehicle, and the server stores and outputs results by number, location, and size of defects.

○ Features

- High speed defect detection and classification

- Available to inspect the gap and flush

- Available to track and manage through schematic detection

- Maximize detection power using the pattern lighting + deep learning algorithms

- Gain ROI through cost (labor cost) reduction and yield improvement

○ Application

- Car Tire

- Refrigerator

- Cell Phone Case

- Able to apply to various glossy products

PAYMENTS DETAILS

- Telegraphic Transfer : T/T

- Name : LAON PEOPLE

SHIPPING

- 723 Pangyo-ro Bundang-gu, Seongnam-si, Gyeonggi-do (13511)

LAON PEOPLE

Seller_MailThe person in charge

LAON PEOPLEAddress

723 Pangyo-ro Bundang-gu, Seongnam-si, Gyeonggi-do (13511)

-

- Business Type :

- Manufacturer

-

- Main Product :

- AI MACHINE VISION

-

- Established :

- 2010-01-18

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Please enter the text on the left image to prevent automatic input.

0 / 4000

CUSTOMER REVIEWS (0)

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- LAON PEOPLE Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★