ITEM SPECIFICS

-

Brand

3DEngineering

-

origin

Republic of Korea

-

Size(Capacity)

Refer to detailed description

-

Gender

ALL

-

Features

Manufacturing Metaverse Map for Virtual Manufacturing Experience

-

age-appropriate

Adult

-

Condition

Metaverse

PRODUCT DESCRIPTION

With 3DAUTOMATION's unique manufacturing metaverse platform where you can experience all manufacturing processes in the world virtually, you can virtually experience and experience manufacturing lines in various fields such as automobile parts manufacturing lines, cosmetics, aviation, and F&B.

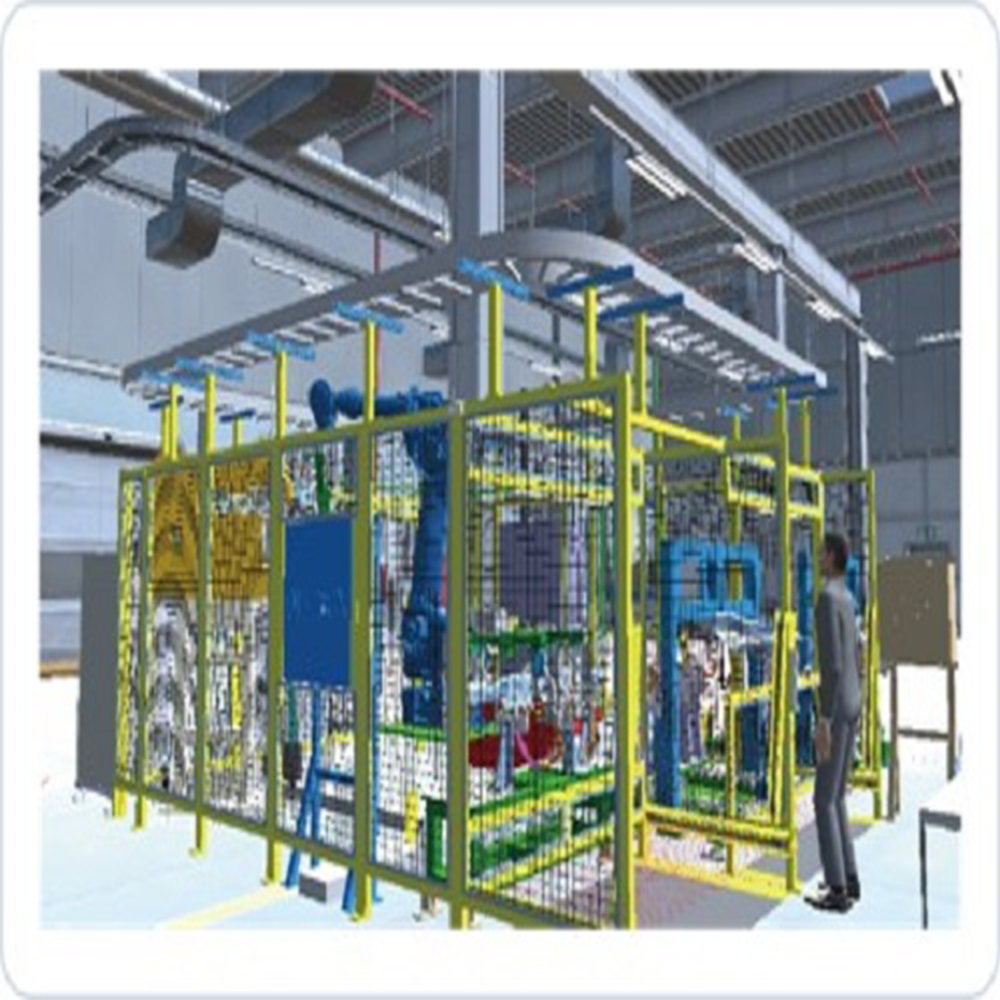

This is one of the digital engineering technologies that establishes the same virtual manufacturing process implemented in the virtual world as a factory in the real world and synchronizes it. Currently, about 40 manufacturing lines can be visited, and a virtual manufacturing environment is implemented by utilizing the process design 3D CAD data used to build the same factory in the real world.

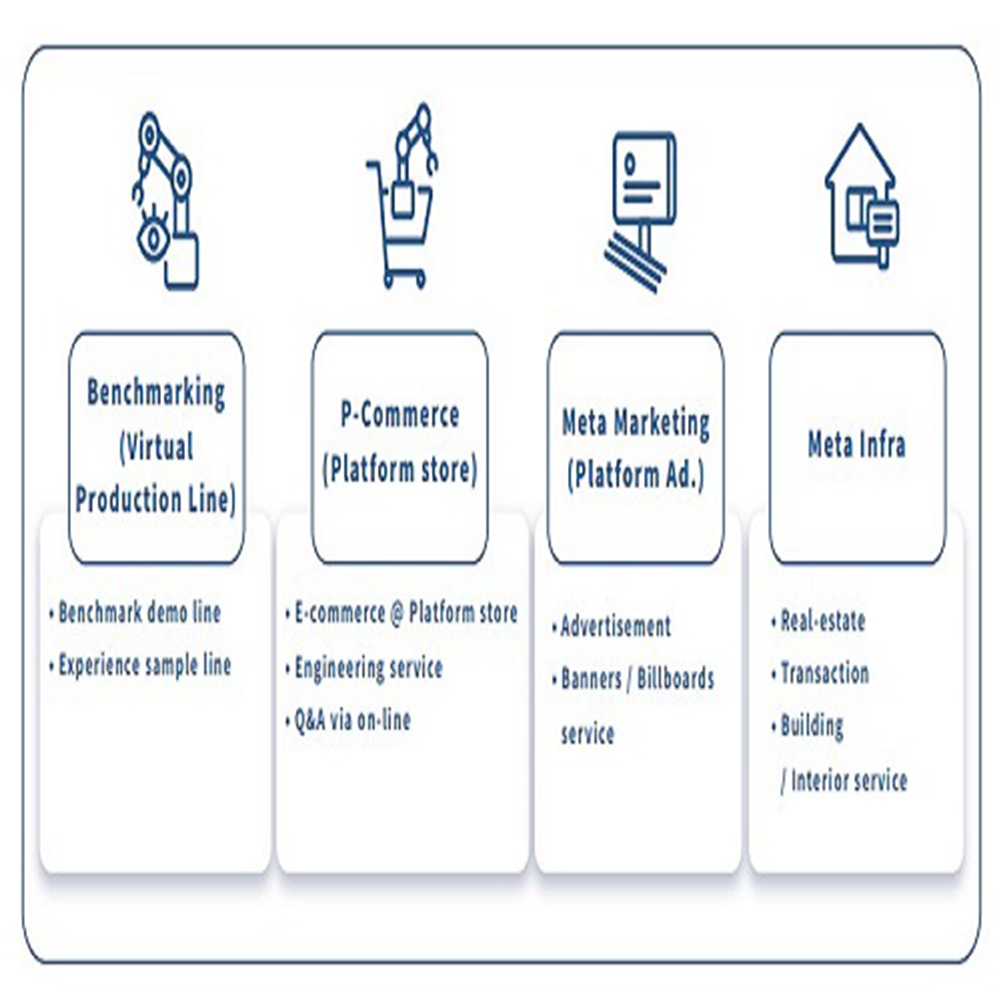

In the 3D metazone, small and medium-sized companies can easily benchmark or receive consultation so that they can easily improve their manufacturing lines or introduce new facilities. Benchmarking Zone, Enterprise Zone, and Metasandanzone are currently being developed.

This is one of the digital engineering technologies that establishes the same virtual manufacturing process implemented in the virtual world as a factory in the real world and synchronizes it. Currently, about 40 manufacturing lines can be visited, and a virtual manufacturing environment is implemented by utilizing the process design 3D CAD data used to build the same factory in the real world.

In the 3D metazone, small and medium-sized companies can easily benchmark or receive consultation so that they can easily improve their manufacturing lines or introduce new facilities. Benchmarking Zone, Enterprise Zone, and Metasandanzone are currently being developed.

The Benchmarking Zone is a place where companies that want to develop manufacturing lines visit and collect examples of manufacturing lines by industry group so that they can benchmark or gain insights for their own development manufacturing lines.

The company zone is an extension of the metaverse of the homepage, and is a place for promoting companies to directly tour and tour the existing 2D image or video-oriented products or manufacturing lines within the metaverse environment.

Metasandanzone is the next stage of smart industrial complex and is an extension of the metaverse of the industrial complex. It is an area configured to visit a specific industrial complex within the metaverse environment, tour various companies located in the industrial complex, and tour manufacturing lines. A manufacturing line is composed of various types of equipment and systems, and one is a complex, composed of multiple companies participating as suppliers.

By experiencing manufacturing lines virtually through the 3D Metazone, you can experience the optimal production manufacturing process with minimal cost and time, and it is possible to make quick decisions and reduce investment. In addition, it is possible to stably develop equipment and produce products because it is possible to select an optimal and verified supplier.

The company zone is an extension of the metaverse of the homepage, and is a place for promoting companies to directly tour and tour the existing 2D image or video-oriented products or manufacturing lines within the metaverse environment.

Metasandanzone is the next stage of smart industrial complex and is an extension of the metaverse of the industrial complex. It is an area configured to visit a specific industrial complex within the metaverse environment, tour various companies located in the industrial complex, and tour manufacturing lines. A manufacturing line is composed of various types of equipment and systems, and one is a complex, composed of multiple companies participating as suppliers.

By experiencing manufacturing lines virtually through the 3D Metazone, you can experience the optimal production manufacturing process with minimal cost and time, and it is possible to make quick decisions and reduce investment. In addition, it is possible to stably develop equipment and produce products because it is possible to select an optimal and verified supplier.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- WK

- OT

- Telegraphic Transfer : T/T

- Name : Hyogyeong Jeon

SHIPPING

Shipping from :

Republic of Korea

- 51 Hoam-ro, Buk-gu, Daegu (41585)

3DAUTOMATION

The person in charge

SANGJIN LEEAddress

51 Hoam-ro, Buk-gu, Daegu (41585)

QRCODE

3DAUTOMATION

Introduction

3DAUTOMATION is a company that specializes in providing DIGITAL ENGINEERING SERVICE to our customers. Our main product is Digital engineering service that is responsible for optimizing the the customers’ manufacturing process through visualization of the same virtual production process as the actual. We provide based on a 3D environment with five digital manufacturing technologies and five mena manufacturing element technologies in the virtual world.

This improves manufacturing processes, productivity and quality. Also it works in a 3D environment so enables high understanding of visualization, resulting in faster decision, making development period and unnecessary cost savings.

We provide a full-cycle of services from planning which is a preparation process stage for manufacturing, process design, element design, emulation, virtual commissioning, facility manufacturing/installation and mass production.

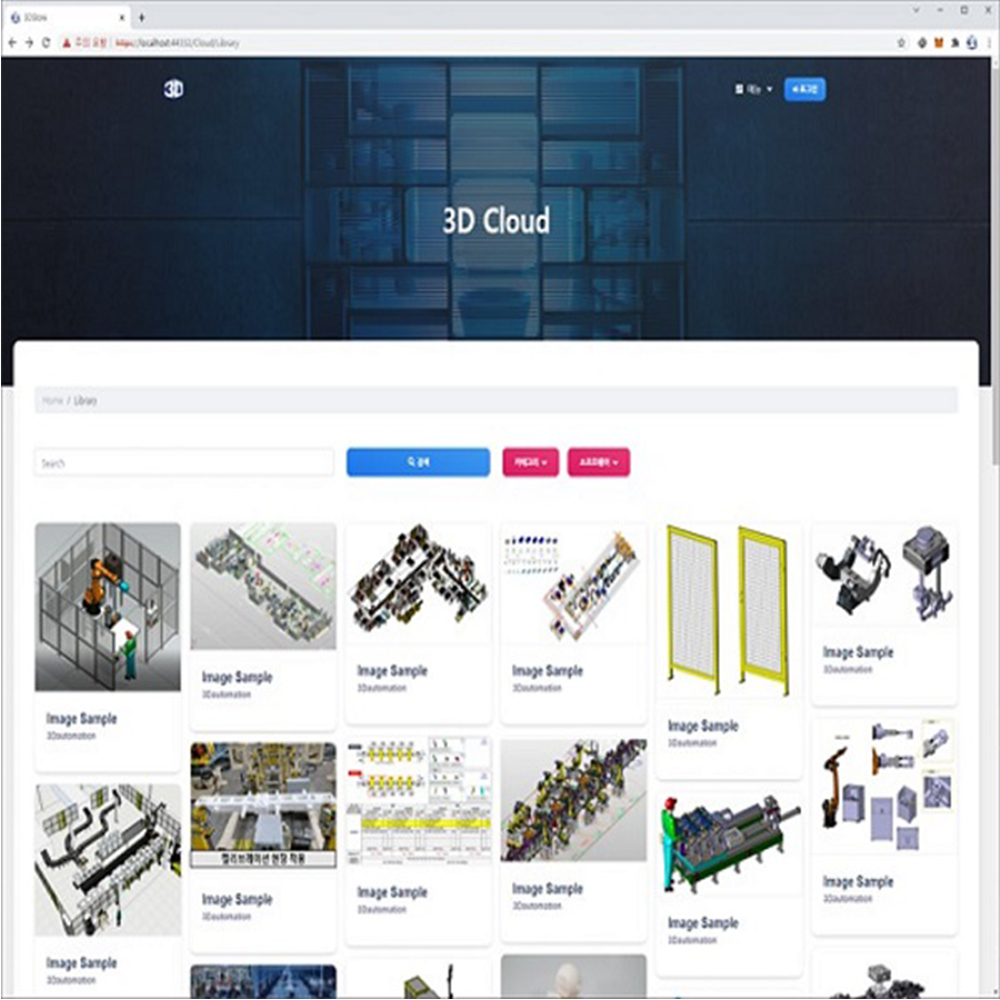

Our company also operates 3Dmetazone, a manufacturing metaverse platform that can experience demo production lines and benchmark by industry and product based on abundant 3D data. 3Dstore, a digital assetization and consignment management platform for 3D CAD data and 3Dremote, a manufacturing management subscription platform that can remotely manage manufacturing.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Digital Engineering service

-

- Established :

- 2017-02-03

-

- Total Annual Revenue :

- 1~2 billion (KRW)

-

- Total Employees :

- 5~10 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 1~2 billion (KRW)

-

- Total export revenue (previous year in USD)

- 0

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items